Change Language :

drylin® N - Design rules

Compensation of misalignments in mm

| Floating bearing | NW-17 | NW-27 | NW-40 | NW-80 |

|---|---|---|---|---|

| LLY | 0.6 | 0.45 | 0.4 | 0.6 |

| LLZ | 0.5 | 0.8 | 1 | 0.8 |

| LLYZ | Y: 0.6, Z: 0.5 | Y: 0.3, Z: 0.4 | Y: 0.4, Z: 2.0 | Y: 0.6, Z: 0.8 |

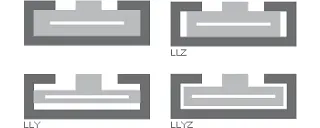

Schematic representation of the floating bearing variants

- LLZ floating bearing in z-direction

- LLY floating bearing in y-direction

- LLYZ floating bearing in yz-direction

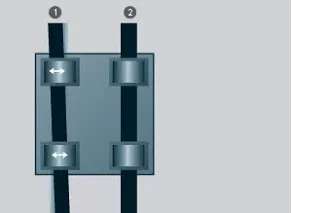

Floating bearings for guide systems

Automatic equalisation of parallelism errors,

1st floating bearing, 2nd fixed bearing

When using systems with two parallel guides, one side must be designed as a floating bearing. There is a suitable locating/non-locating bearing solution for every installation position, whether horizontal, vertical or lateral. This installation method prevents stiffness or jamming of the guide in the event of parallelism deviations between the guides. The floating bearing is realised by the controlled extension of the clearance in the direction of the anticipated parallelism error. This creates an additional degree of freedom on one side.

During installation, it is important to ensure that the floating bearing has approximately the same amount of clearance in both directions. The design of the locating/non-locating bearing system recommended by us can be found in the illustrations in the individual chapters of the systems. The connection surfaces for the guidance and carriages should have good evenness (e.g. milled surface) in order to avoid tension in the system. Minor unevenness in the connection surfaces can be compensated to a certain extent by floating bearings.

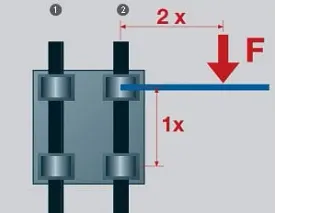

Eccentric forces

The 2:1 rule,

1st floating bearing, 2nd fixed bearing

A few recommendations must be observed for the successful use of maintenance-free drylin® linear bearings: If the distance between the driving force and the fixed bearing is more than twice the bearing distance (2:1 rule), a static friction coefficient of 0.25 theoretically leads to jamming of the guidance.

The principle is not dependent on the load or the drive force. It is a product of friction and always relates to the locating bearing. The further away the drive is from the guide bearing, the greater the wear and the drive force required.

If the 2:1 rule is not observed when using linear plain bearings, the result is uneven movement or even blocking of the system. This can often be remedied with relatively simple modifications.

If you have any questions about the design and/or installation, please contact our application consultants.

Consulting

I look forward to answering your questions

Michael Hornung+49 2203 9649 0Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Chat-Service

Monday to Thursday from 8 am - 6 pm.

WhatsApp-Service:

Monday to Thursday from 8 am - 4 pm.