Change Language :

igus cleanroom laboratory for ISO class 1 components

Innovative igus cleanroom technology successfully put to the test! Guaranteed particle-free!

igus is one of the leading manufacturers of energy chains in the area of cleanroom technology and has successfully had its products tested since 1997. To develop new cleanroom-compatible products more quickly, Fraunhofer IPA, acting as a development and certification partner on behalf of igus, has designed and built a customised cleanroom laboratory with an ISO Cleanroom Class 1 system in Cologne. In the new laboratory, the plastics specialist can perform customer tests and new developments in advance under real-world conditions in the shortest possible time.

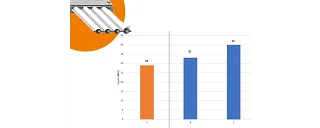

Sound measurement of the e-skin flat

e-skin flat has a noise level of only 29dB(A).

This test shows how quiet the igus e-skin flat (A) cable guidance system is. Compared to ribbon cables (B) and (C) from competitors, the e-skin flat only has a noise level of 29dB(A) - tested in the igus laboratory, Cologne at 1.5m/s unsupported, on standard support for noise measurement (damped plate, without guide). 1m distance from the measuring device.

Endurance test of the e-skin corrugated tube

The corrugated tube e-skin has been specially developed for cleanroom applications. In the laboratory, it withstood more than 6.4 million double strokes at 3m/s under realistic conditions.

Tested, proven, tried and tested - our products

EN ISO 14644: Standard for determining the cleanroom classification

EN ISO 14644 (DIN EN ISO 14644 in Germany) is an internationally recognised standard for cleanrooms and cleanroom areas. The standard can be used to categorise rooms into cleanroom classes (ISO 1-9). The standard also takes into account aspects relating to the planning, operation and monitoring of cleanroom facilities.

Originally developed in the semiconductor industry, EN ISO 14644 replaced the old US FED STD 209E standard in 2001. It has since become established in numerous industries, including the aerospace, optical, pharmaceutical, food, medical technology and healthcare sectors.

To categorise cleanrooms into cleanroom classes, EN ISO 14644 focuses on the concentration of particles in the air. The standard specifies limit values for the maximum permissible particle concentration per cubic metre of air. It also categorises the degree of cleanliness into cleanroom classes ISO 1-9. ISO Class 1 cleanrooms achieve the highest level of cleanliness. This means that a maximum of ten particles with a maximum size of 0.1 micrometres may be present in one cubic metre of air.

In order to determine the concentration uniformly, the standard specifies recognised test methods in addition to particle limit values. Modern particle measuring devices are often equipped with a laser diode for the most accurate measurement possible. The minimum number of measuring points per area can be found in a table. The room fulfils the requirements if the average value of each measuring point does not exceed the limit values.

More information

Consulting

I look forward to answering your questions

Bastian Lenz+49 172 3969697Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm