Energy chains - chemical resistance of igumid materials

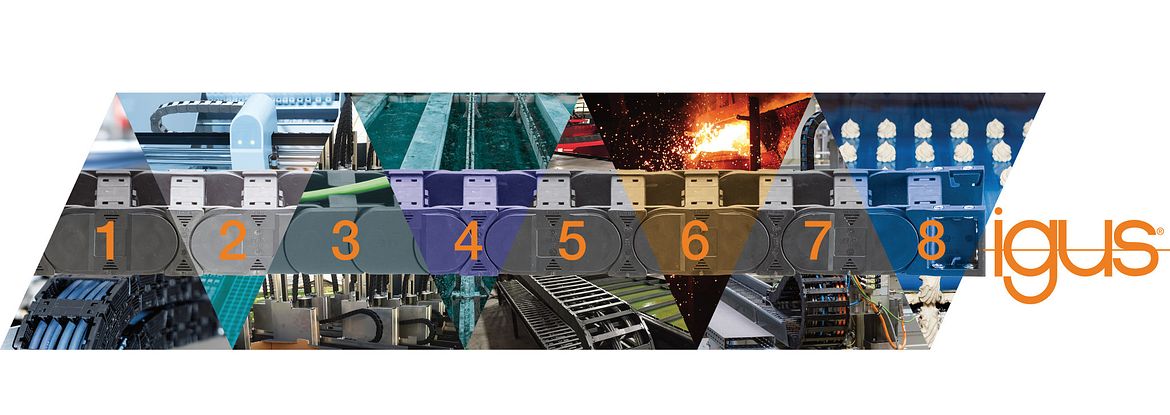

The materials from which energy chains are manufactured must withstand a great deal: compressive load and tensile strain, abrasion resistance, excellent toughness, high modulus of elasticity, high stability at high and low temperatures, suitable for outdoor use. To ensure this, igus energy chains are made from the high-performance polymer igumid. Numerous application examples, from refrigerator blocks to steel mills, prove this.

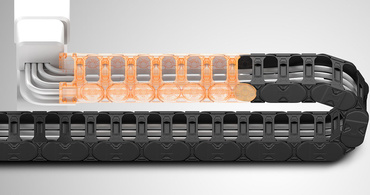

The e-chains® in this series are extremely easy to fill. Pliant split crossbars allow cables to be pressed in easily by hand. That is why a material that combines the necessary flexibility and stability has been selected.

The following list provides detailed information about the resistance of igus' igumid G, NB, and TE materials to many chemical substances. The values specified are values determined by laboratory tests and are material-specific. All specifications apply to black energy chains. If your chemical is not listed, contact us. We will be happy to carry out a test upon request.

igumid G - the base material for most applications

With the base material igumid G alone, most of the possible applications can be implemented. The cost-effective material fulfils even conflicting requirements. It can handle continuous temperatures ranging from -40°C to far above 100°C, allowing use in cold store or steel mills. Even applications in snow and ice run smoothly in practice. Discover energy chains made with igumid G.igumid NB gives easy chain® energy chains the required flexibility

Comparable performance values apply to igumid NB, the standard material for all energy chains of the type [link url=" /e-chains/linear-movement?sort=3&inch=false&recomechainspre=2&echainsyst=1" title="easy chain®"].The e-chains® in this series are extremely easy to fill. Pliant split crossbars allow cables to be pressed in easily by hand. That is why a material that combines the necessary flexibility and stability has been selected.

igumid TE

The igumid TE is used when still higher demands are placed on the permanent elasticity and flexibility of energy chain components. It is used, for e.g, in the connectors of the E6 chains developed for extreme dynamics or in the exceptionally tear-resistant and flexible lids of the zipper e-chains®.igumid EG+ - withstands even aggressive chemicals

The newest member of the chain material family is igumid EG+. The material is characterised by extremely low total moisture absorption and therefore also has a very high resistance to chemicals. The igumid EG+ has been specifically developed for applications with aggressive chemicals, such as those used, for e.g. in galvanisation or fertiliser production, and is used there both for energy supply chains and trough systems. Where expensive stainless steel was previously necessary as a trough material, igumid EG+ now offers a cost-effective alternative. The material can be recognised immediately because of its blue colour and can be used for most e-chain® series in a temperature range from 0°C to +100°C. It is free of halogen and silicone and RoHS-compliant.igumid HT protects against red-hot swarf

If energy, signals and media need to be moved flexibly in machine tools, the use of e-tubes is ideal. Their closed design prevents swarf from getting inside them. Tubes made of the special igumid HT material also ensure that swarf as hot as 850°C does not stick. All R2, R4, and RX series tubes are available in a heat-resistant HT version. Manufacturers of foundry machines and other metal processing plants thus have the opportunity to replace metal energy supply systems with more flexible and significantly lighter energy chains made of high-performance plastic.igumid DT is magnetically detectable

The development of the plastic compound igumid DT was intended in particular for applications throughout food production. The basic material was modified so that a fragment of just 1mm can be detected by all commonly used detection systems. In this way, any splinters can be detected and automatically removed. Request now.igumid ESD: protection against electrostatic charges

ESD-compliant solutions and tools are used in many industries to protect sensitive electronic components from electrostatic discharges. This is especially important for moving parts such as energy supplies. The igumid ESD gives the igus® product range a material that was designed specifically for this challenging application and that can discharge electrostatic charges immediately in a controlled manner. Unlike applied conductive surface coatings or volatile incorporated antistatic agents, the additives used offer long-lasting conductivity that makes maintenance unnecessary. The igumid ESD is also the perfect material for energy chains used in zones that are susceptible to gas or dust explosion and thus in explosion risk areas. Such work environments occur primarily in the chemicals industry, but also wherever there are filling processes for powdery or dusty goods. The igumid ESD's ability to discharge static charges can mean the elimination of potential ignition sources in environments that are susceptible to explosion in such applications. The plastic, tested with over 10 million cycles, even exceeds the standard igumid G material in some mechanical requirements.igumid XXL is meant for large unsupported lengths and higher fill weights

Up to seven metres of unsupported length, without guide troughs and supports: this requirement for the optimal e-chain® solution can be met with the igumid XXL material. Alternatively, greater fill weights can be achieved with the same unsupported length. This also saves installation time and cost, since gliding applications generally require longer chains, additional guide troughs, and more installation space. The material is used primarily in applications involving handling and conveyor systems, construction and other heavy machinery, and large robots. Request now.The following list provides detailed information about the resistance of igus' igumid G, NB, and TE materials to many chemical substances. The values specified are values determined by laboratory tests and are material-specific. All specifications apply to black energy chains. If your chemical is not listed, contact us. We will be happy to carry out a test upon request.

Legend:++ = resistant | + = conditionally resistant | - = non-resistant | Sat. aq. sol. = saturated aqueous solution

| Medium | Concentration weight % | igumid G and NB | igumid TE |

|---|---|---|---|

| Acetone | 100 | ++ | ++ |

| Formic acid (aqueous) | 2 | + | ++ |

| Ammonia (aqueous) | 10 | ++ | ++ |

| Gasoline | 100 | ++ | ++ |

| Benzene | 100 | ++ | ++ |

| Bitumen | 100 | + | - |

| Boric acid (aqueous) | 10 | ++ | + |

| Butyric acid | 100 | + | - |

| Calcium chloride (aqueous) | Sat. aq. sol. | ++ | ++ |

| Chlorinated hydrocarbons | ++ | + | |

| Chlorine water | Sat. aq. sol. | - | - |

| Chromic acid (aqueous) | 1 | + | - |

| Diesel oil | 100 | ++ | ++ |

| Acetic acid | 2 | ++ | + |

| Colour | ++ | ++ | |

| Greases, cooking fat | ++ | ++ | |

| Fluorinated hydrocarbons | ++ | ++ | |

| Formaldehyde (aqueous) | 30 | + | + |

| Hydraulic oils | ++ | + | |

| Caustic potash | 10 | ++ | ++ |

| Potassium carbonate (aqueous) | 60 | ++ | ++ |

| Potassium sulphate (aqueous) | 100 | ++ | ++ |

| Methyl acetate | 100 | ++ | ++ |

| Milk | ++ | ++ | |

| Mineral oil | ++ | ++ | |

| Sodium carbonate (aqueous) | 50 | ++ | ++ |

| Oil, lubricating oil | ++ | ++ | |

| Oil, cooking | ++ | ++ | |

| Oleic acid | 100 | ++ | ++ |

| Paraffin oil | ++ | ++ | |

| Perchloroethylene | 100 | ++ | - |

| Polyester resins (with styrene) | ++ | ++ | |

| Propane gas | ++ | ++ | |

| Mercury | ++ | ++ | |

| Hydrochloric acid | pH2 | + | - |

| Hydrochloric acid | 2 | - | - |

| Hydrochloric acid | 10 | - | - |

| Ink, printing ink | ++ | ++ | |

| Vaseline | ++ | ++ | |

| Tartaric acid | + | ++ | |

| Zinc sulphate (aqueous) | 10 | ++ | - |

Selected application examples with energy chains

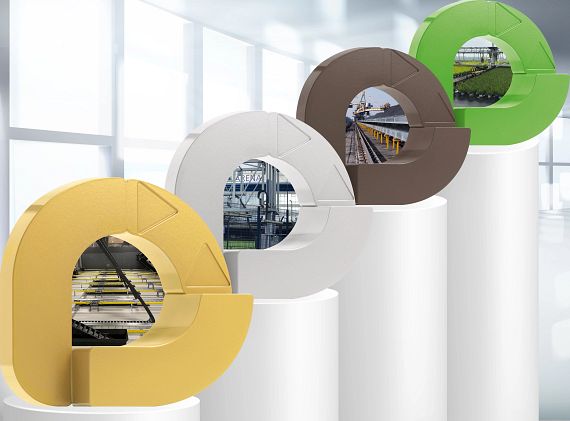

Innovative applications of the 2022 vector award

Discover the winners of the 2022 vector award with their innovative applications:

- Golden vector: Multi-purpose hall, GEPBER-Szinpad Kft.

- Silver vector: Turf lighting system, RHENAC GreenTec AG

- Bronze vector: Bucket wheel equipment, Talwandi Sabo Power Limited

- Green vector: Precision watering trolley, Dercks Gartenbau GmbH

Discover vector applications now

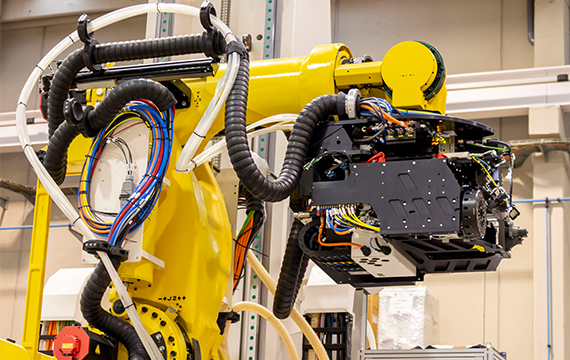

Robot end effector

LOXIN chose motion plastic specialist igus, whose triflex range carried the right solution. These hose-like protective cages made of wear-resistant plastic follow even the most extreme 3D movements of industrial robots. The cables are protected against mechanical stress due to tensile load, torsion and expansion.

Learn more

Lignite excavator

Travels of 615m and in operation without failure since 2008

Compared to the previously installed festoon systems, e-chain systems of the 5050RHD series reduce the necessary cable lengths and the installation space needed. The 5050RHD series is used in the large lignite excavator in the Czech Republic. The travels amount to 615m.

Learn more

Palletiser

Short installation time, long service life

Beyer Maschinenbau GmbH was looking for an energy supply system that provides the stability and durability needed in its machines for the beverage industry. The E4.1L energy supply system from igus meets more than these requirements. Due to its design, it is easy to fill and assemble while being cable-friendly at the same time. It therefore shortens assembly times and ensures long-lasting cables.

Learn more

Laser cutting machines

Everything from one source, tested reliability and fast installation

Thanks to a Kanban procedure, the customer receives the ready-to-install energy chain systems just-in-time at the installation location, as a result of which installation times are reduced and parts do not have to be stored.

Learn more

Production line conveyor

Avoiding machine failures

An automotive supplier from Austria relies on igus smart plastics for these assembly lines in order to increase dependability and implement predictive maintenance.

Learn more

More information

Energy chains shop

With more than 100,000 products: From small to mid-sized to large energy chains to special solutions.To the shop

Energy chain knowledge base

Find important information, questions and answers regarding energy chains.Go to the knowledge base

Online seminars

Benefit from the knowledge and experience of our experts.Go to the online seminars

Tested!

Every year, 3,000 e-chain tests are performed in order to ensure that they can withstand the hardest of conditions.

Go to the Energy Chains test laboratory