Flexible 3D energy chains as cable guidance for riveting robots for aircraft construction

In aircraft construction, e-chains carry a high cable weight during fast robot movements.

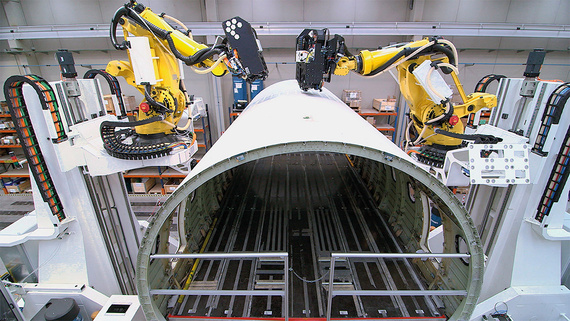

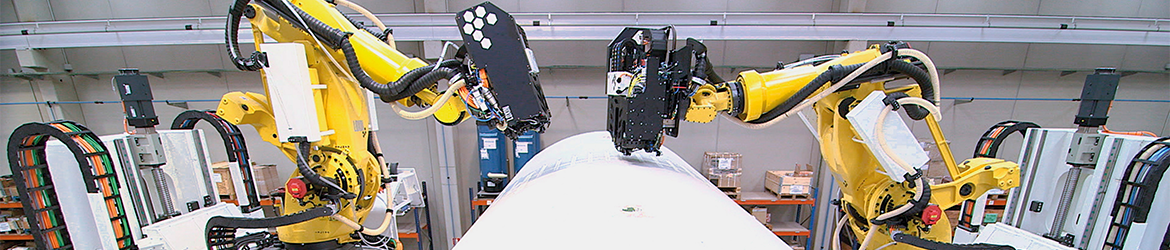

The company Loxin 2002 succeeded in automating the riveting process. The multi-axis robots stand to the left and right of a large aircraft manufacturer's jacked-up aircraft fuselage in production. The robots are mounted on platforms that can be moved to a height of several metres using linear units. Once at the right height, the robot moves to the working point via six axes with millimetre precision. It drills a hole in the metal, mills a recess for the rivet head, vacuums up the dust, applies a sealant and sets the rivet.Profile

- What was needed: 3D energy chain system triflex R with retraction system triflex RSE, twisterchain

- Requirements: Reduce the number and weight of cables, avoid downtime and cable breaks

- Industry: Aerospace, aircraft construction

- Success for the customer: Thanks to triflex 3D cable guides, the robots achieve better mobility, which leads to savings in assembly times.

Problem

The ARITEX Group company LOXIN was looking for a suitable solution for the energy supply of the multi-axis robots. The problem, however, was to find a cable solution that was at the same time reliable, robust and trustworthy. This was made more difficult by the high number and the resulting high weight of the cables to be guided. The tools on the robot's end effector are connected to numerous energy, pneumatic and data cables. These cables must be able to follow the arm's contortions perfectly, even at high speeds. LOXIN had used conventional corrugated tubes in the past, but these did not turn out to be a solution. Due to the rapid wear caused by friction, they broke in many places, which would have led to the entire tube being replaced during operation, including the disassembly of the cable. The result was machine downtime for several days.Solution

LOXIN chose our triflex range. The hose-like protective cages made of wear-resistant plastic follow even the most extreme 3D movements of industrial robots. The cables are protected against mechanical stress due to tensile load, torsion and expansion. With the triflex RSE retraction system the energy chains move close to the arm and therefore do not hit the aircraft. If the robot arm returns to its starting position after a movement, the mechanical system pulls the chain back. The robot arm is guaranteed complete freedom of movement without parts of the chain rubbing against each other or loops forming in the process. If a chain link reaches the end of its service life, it can be replaced quickly and easily.We use another energy chain system on the robot arm, the twisterchain . It protects cables from the base of the robot arm to the first axis and moves in a guide trough. If the robot arm turns, the chain folds as the upper run of the chain rests on the lower run.

In this way, a circular movement of up to 540° is achieved at speeds of up to 1m/s. The twisterchain is extremely wear-resistant and has a proven service life of over one million cycles.