Robust bearing technology for unscrewing and emptying bottles

Reliable plain bearings in confined installation spaces and continuous operation in Rink beverage machines

The designers of Rink GmbH & Co KG select all moving machine components with great care. The bearing and drive elements are subjected to heavy loads. This is because Rink manufactures machines for the fully automated uncorking or unscrewing of caps of returnable bottles that work at a speed of up to 60,000 bottles per hour. Under these conditions, iglidur plastic bearings prove their worth - among others in the new carousel-type machines with increased throughput capacity.Profile

- What was needed: drylin R linear bearings with drylin linear liner and drylin R linear shafts, iglidur plain bearings, iglidur guide rings

- Requirements: A Rink machine uncorks a million returnable bottles in just two-and-a-half eight-hour shifts, so all components must be capable of performing under continuous operation, and in a very compact installation space. In the beverage industry, they must also be free of lubricants.

- Industry: Beverage industry, fluid technology

- Success for the customer: The linear and rotary plain bearings are characterised by very good sliding properties with a long service life and are also ideally suited for use in the beverage industry because they are maintenance-free and do not require lubricants.

Problem

Rink GmbH & Co. KG develops and produces systems that prepare returnable bottles for reuse. Up to 60,000 corks are removed or caps are unscrewed per hour. Within just two and a half eight-hour shifts, a machine uncorks a million returnable bottles, and does so in a very compact installation space. All moving parts reach very high cycle numbers within a very short time and are subjected to very high stress.Rotary machines for unscrewing bottles:

At present, rotary machines that unscrew individual bottles are in great demand. Although these machines need more space in the overall plant, the user is more flexible. Because this requirement increasingly applies to higher throughputs, Rink has now expanded the rotary machine range and developed a new machine type for unscrewing up to 30,000 individual bottles per hour. Among other things, a linear bearing of the tool head was required for the new rotary machines, which moves the rotary unscrewing device up and down in a wave-like manner.

Unscrewing of bottles in small packs:

In another project, the developers at Rink also optimised the bearing position. This is a new and very compact unscrewing head that dips into boxes with small divisions for small barrels. In the linear unit for the immersion movement

Valve for emptying bottles:

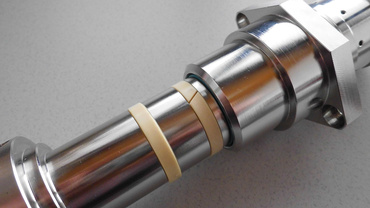

In a third application example, the designers dealt with a valve that is used in the systems for emptying bottles. The machine head with the valves moves into the box, the valves seal, build up pressure and press the liquid out. Due to the height adjustment, a vertical movement of the valves with corresponding sealing is required. Originally, Rink used classic piston guide rings for the hydraulic cylinders for this task, which often did not provide the desired stability.

Solution

The fact that plain bearings from our bearing range were used in the design of these plant components is something that is self-evident for the Rink engineers. Our plain bearings offer very good sliding properties with a long service life and are therefore ideally suited for use in the beverage industry because they are maintenance-free and do not require lubricants.The designers at Rink use very different bearings in almost all machine types:

drylin R linear bearings with linear liner and stainless steel shaft.

In the smaller rotary machines, plain bearings made from the all-round material iglidur J are used.

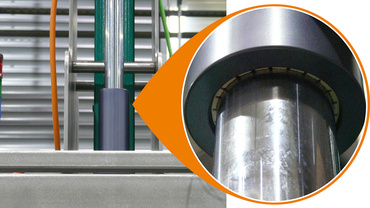

For the new larger models, the designers tested alternatives such as iglidur J200 and iglidur E7 and both aluminium and stainless steel shafts to optimise running performance. Today, used here are the drylin RJUM linear bearing complete with JUM-01 linear liner and a precision stainless steel shaft of the AWMP type (see picture 1 below). The result is a very cost-effective coefficient of friction. The service life could also be tripled.

iglidur Z plain bearings

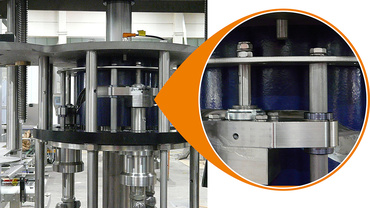

Plain bearings made of iglidur Z are now used for the insertion movement of the unscrewing head, after the first unscrewing heads were equipped with bearings made of iglidur J and iglidur W300 (picture 2). The headrest is extremely wear-resistant and the users are very satisfied.

Guide ring made of iglidur J

Finally, a guide ring made of iglidur J is used to support the valve head when emptying bottles. The high-performance polymer is resistant to chemicals and is characterised by low moisture absorption (picture 3). In addition, the guide ring made of iglidur J is easy to install and is reverse compatible. This allowed the surrounding structure to remain unchanged. These bearings have now been the Rink standard for some years - especially as they are available quickly and cost-effectively as catalogue parts.

Olaf Staave, Design Manager at Rink GmbH & Co. KG