iglidur® HSD350 – material data

Technical data

| General specifications | Unit | iglidur® HSD350 | Testing method |

| Density | g/cm³ | 1,39 | DIN EN ISO 1183–1 |

| Colour | beige | ||

| Max. moisture absorption at 23 °C/50% r.h. | % weight | 0,6 | ISO 175 |

| Max. total moisture absorption | % weight | 1,2 | ISO 62 |

| Coefficient of friction, dynamic, against steel | µ | 0,07 - 0,23 | |

| pv value, max. (dry) | MPa · m/s | 0,30 | |

Mechanical properties | |||

| Flexural modulus | MPa | 2.150 | DIN EN ISO 178 |

| Flexural strength at +20°C | MPa | 67 | DIN EN ISO 178 |

| Compressive strength | MPa | 44 | |

| Max. recommended surface pressure (+20°C) | MPa | 30 | |

| Shore-D hardness | 77 | DIN 53505 | |

Physical and thermal properties | |||

| Max. application temperature long-term | °C | +180 | |

| Max. application temperature short-term | °C | +210 | |

| Min. application temperature | °C | -40 | |

| Thermal conductivity | [W/m · K] | 0,24 | ASTM C 177 |

| Coefficient of thermal expansion (at +23 °C) | [K-1 · 10-5] | 7 | DIN 53752 |

Electrical properties | |||

| Specific volume resistance | Ωcm | > 1013 | DIN IEC 93 |

| Surface resistance | Ω | > 1014 | DIN 53482 |

Table 01: Material properties table

Download datasheet

iglidur HSD350 was specially developed for use in applications where decontamination by steam (e.g. in autoclaves) is necessary. iglidur® HSD350 offers an excellent price-performance ratio.

Mechanical properties

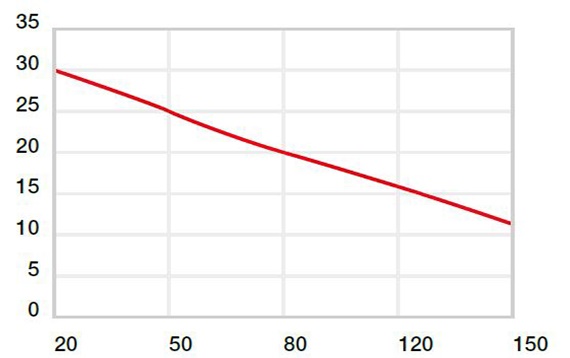

With increasing temperatures, the compressive strength of iglidur® HSD350 plain bearings decreases. The diagram 02 shows this inverse relationship. The recommended maximum surface pressure is a mechanical material parameter. No conclusions regarding the tribological properties can be drawn from this.

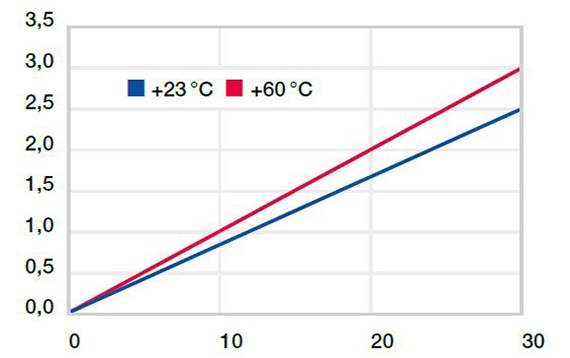

Diagram 03 shows the elastic deformation of iglidur® at radial loads. At the maximum recommended surface pressure of 30 MPa, the deformation is less than 2%. A possible deformation could be, among others, dependant on the duty cycle of the load.

Maximum running speed

| m/s | Rotating | Oscillating | linear |

| Long-term | 1,1 | 0,8 | 3,0 |

| Short-term | 1,2 | 1,0 | 3,2 |

Table 02: Maximum surface speeds

Permissible surface speeds

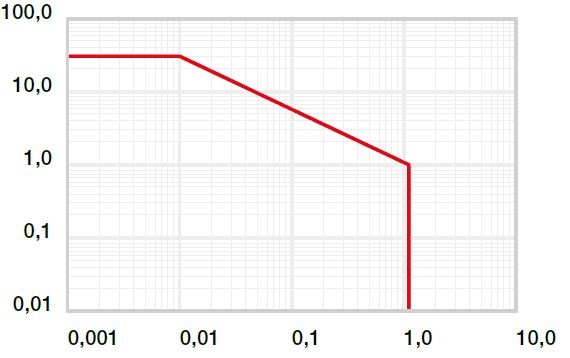

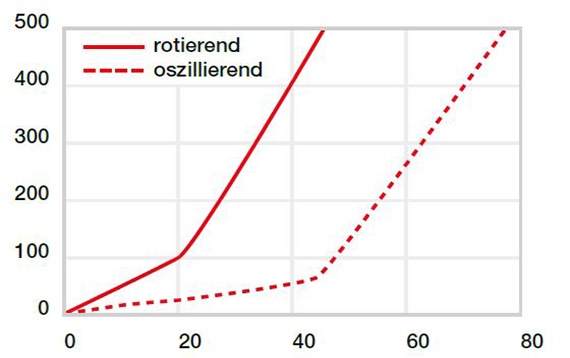

Due to its rather good thermal conductivity and thermal resistance, iglidur HSD350 is suitable for speeds in the medium range. The permissible surface speed decreases with increasing surface pressure.| iglidur® HSD350 | Application temperature |

| Minimum | -40°C |

| Max. long-term | +180°C |

| Maximum, short-term | +210°C |

| In addition secure axially from | +130°C |

Table 03: Temperature limits

Temperature

The ambient temperatures strongly influence the properties of plain bearings. According to its field of application as autoclavable material, iglidur® HSD350 offers good thermal resistance. For temperatures over 130°C an axial securing of bearings is required.

Friction and wear

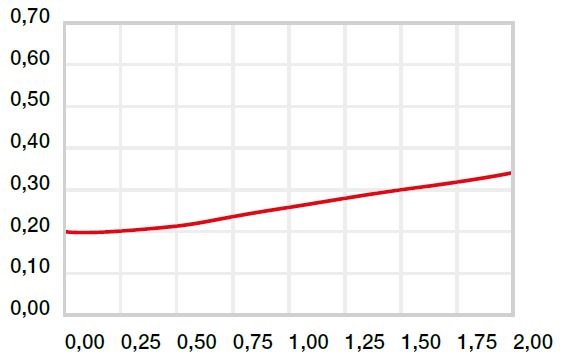

The coefficient of friction increases constantly and slowly over the speed, but remains below 0.3 μ up to a speed of 2.0 m/s.| iglidur® HSD350 | Dry | Greases | Oil | Water |

| C. o. f. µ | 0,07 - 0,23 | 0,09 | 0,04 | 0,04 |

Table 04: Coefficient of friction against steel

(Ra = 1 µm, 50 HRC)

Shaft materials

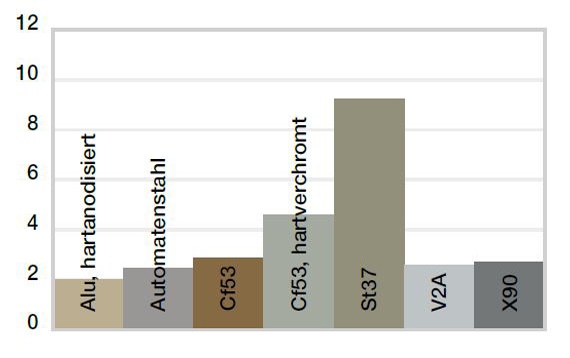

Diagrams 05 and 06 display a summary of the test results with different shaft materials conducted with plain bearings made from iglidur® HSD350. At 0.3 m/s and 1 MPa surface pressure, a wide variety of shafts are suitable and provide good wear results. Hard-anodised aluminium, free cutting steel, hard-chromed Cf53, 304 stainless steel and high grade steel exhibit low wear. If the shaft material you plan on using is not shown in these test results, please contact us.Shaft materials

| Chemicals | Resistance |

| Alcohol | + up to 0 |

| Hydrocarbons | + |

| Greases, oils without additives | + |

| Fuels | + up to 0 |

| Diluted acids | + |

| Strong acids | 0 |

| Diluted alkalines | + |

| Strong alkalines | 0 |

All information given at room temperature [+20°C]

Table 04: Chemical resistance

Moisture absorption

The moisture absorption of iglidur® HSD350 plain bearings is approximately 0.6% weight in standard climatic conditions. The saturation limit in water is 1.2 %weight. These values are so low that a moisture expansion need to be considered only in extreme cases.Radiation resistance

Plain bearings made from iglidur® HSD350 are resistant up to a radiation intensity of 3 · 10² Gy.UV resistance

When subjected to UV radiation, iglidur® HSD350 plain bearings change colour. However, hardness, compressive strength and wear resistance of the material do not change.Vacuum

In vacuum, the moisture content is released as vapour. Due to its low moisture absorption, use in a vacuum is possible.Electrical properties

| Specific volume resistance | > 1013 Ωcm |

| Surface resistance | > 1014 Ω |

| Ø d1 [mm] | Housing H7 [mm] | Plain bearing F10 [mm] | Shaft h9 [mm] |

| to 3 | +0,000 +0,010 | +0,006 +0,046 | -0,025 +0,000 |

| > 3 to 6 | +0,000 +0,012 | +0,010 +0,058 | -0,030 +0,000 |

| > 6 to 10 | +0,000 +0,015 | +0,013 +0,071 | -0,036 +0,000 |

| > 10 to 18 | +0,000 +0,018 | +0,016 +0,086 | -0,043 +0,000 |

| > 18 to 30 | +0,000 +0,021 | +0,020 +0,104 | -0,052 +0,000 |

| > 30 to 50 | +0,000 +0,025 | +0,025 +0,125 | -0,062 +0,000 |

| > 50 to 80 | +0,000 +0,030 | +0,030 +0,150 | -0,074 +0,000 |

| > 80 to 120 | +0,000 +0,035 | +0,036 +0,176 | -0,087 +0,000 |

| > 120 to 180 | +0,000 +0,040 | +0,043 +0,203 | +0,000 +0,100 |

Table 05: Important tolerances for plain bearings according to ISO 3547-1 after press-fit