iglidur plain bearings - Temperatures

![Overview of the long-term and short-term upper application temperature limits [°C]](/contentData/wpck/images/global/multi_column/sizes/iglidur_intro_a10_570.gif)

The temperature resistance of high-performance polymer plain bearings is usually underestimated. Data is often found in the literature about the continuous operating temperature. The continuous operating temperature is the highest temperature, which the plastic can withstand for a period of time without a reduction in the tensile strength of the material above or below a pre-specified value. This standardised test however yields only a less relevant characteristic value, as bearings are almost always subjected to a load. The application temperatures of the materials are more revealing.

Table 01: Temperature at which additional securing of the iglidur plain bearing is required

| Material | Temp. [°C] |

| iglidur® G | +100 |

| iglidur® J | +60 |

| iglidur® M250 | +60 |

| iglidur® W300 | +60 |

| iglidur® X | +135 |

| iglidur® K | +70 |

| iglidur® P | +90 |

| iglidur® GLW | +80 |

| iglidur® J260 | +80 |

| iglidur® J3 | +60 |

| iglidur® J350 | +150 |

| iglidur® L250 | +55 |

| iglidur® R | +50 |

| iglidur® J200 | +60 |

| iglidur® D | +50 |

| iglidur® V400 | +100 |

| iglidur® X6 | +160 |

| iglidur® Z | +145 |

| iglidur® UW500 | +150 |

| iglidur® H | +120 |

| iglidur® H1 | +80 |

| iglidur® H370 | +100 |

| iglidur® H2 | +110 |

| iglidur® A180 | +60 |

| iglidur® A200 | +50 |

| iglidur® A350 | +140 |

| iglidur® A500 | +130 |

| iglidur® A290 | +110 |

| iglidur® T220 | +50 |

| iglidur® F | +105 |

| iglidur® H4 | +110 |

| iglidur® Q | +50 |

| iglidur® UW | +80 |

| iglidur® B | +50 |

| iglidur® C | +40 |

Application temperatures

The minimum application temperature is the temperature below which the material is so rigid and hard that it becomes too brittle for standard applications. The maximum continuous application temperature is the temperature which the material can endure without the properties changing considerably.The maximum, short-term application temperature is the temperature above which the material becomes so soft, that it can only withstand small external loads.

"Short term" is defined as a period of a few minutes. If the plain bearings are moved axially or axial forces occur, there is more opportunity for the bearing to lose press-fit. In these cases, axial securing of the bearing is necessary in addition to the press-fit.

The table 01 shows the temperature at which additional securing of the iglidur® plain bearing is required, even under low axial loads. The greater the forces, the more reasons to engage such a fastening.

Temperature and load

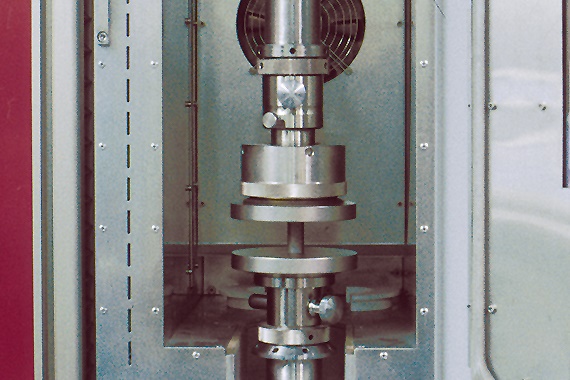

The diagrams 02 and 03 show the maximum recommended surface pressure [p] of the iglidur plain bearings as a function of temperature. With increasing temperature, this value decreases continuously.

With plain bearings it is important to note that, due to the friction, the bearing temperature may be higher than the ambient temperature.

Coefficient of thermal expansion

The thermal linear expansion of polymers is about 10 to 20 times higher than that of metals. In contrast to metal, this expansion is non-linear in plastics. The coefficient of thermal expansion of the iglidur plain bearing is a significant reason for the bearing clearance. At the given application clearance, seizing of the bearing to the shaft does not occur at high temperatures. The coefficient of thermal expansion of iglidur plain bearings was examined for significant temperature ranges and the results are given in the individual materials tables, at the start of each chapter.