iglidur® G1 - Material data

Technical data

| General specifications | Unit | iglidur® G1 | Testing method |

| Density | g/cm³ | 1,58 | |

| Colour | grey | ||

| Max. moisture absorption at 23 °C/50% r.h. | % weight | 0,2 | DIN 53495 |

| Max. total moisture absorption | % weight | 1,7 | |

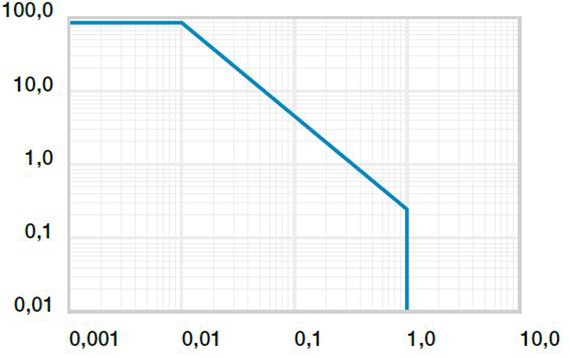

| Coefficient of friction, dynamic, against steel | µ | 0,10 - 0,29 | |

| pv value, max. (dry) | MPa · m/s | 0,60 | |

Mechanical properties | |||

| Flexural modulus | MPa | 11.486 | DIN 53457 |

| Flexural strength at +20°C | MPa | 178 | |

| Compressive strength | MPa | 115 | |

| Max. recommended surface pressure (+20°C) | MPa | 91 | |

| Shore-D hardness | 81 | DIN 53505 | |

Physical and thermal properties | |||

| Max. application temperature long-term | °C | +180 | |

| Max. application temperature short-term | °C | +220 | |

| Min. application temperature | °C | -40 | |

| Thermal conductivity | [W/m · K] | 0,25 | ASTM C 177 |

| Coefficient of thermal expansion (at +23 °C) | [K-1 · 10-5] | 3,7 | DIN 53752 |

Electrical properties | |||

| Specific volume resistance | Ωcm | > 109 | DIN IEC 93 |

| Surface resistance | Ω | > 109 | DIN 53482 |

Table 01: Material properties table

Download datasheet

The requirement profile is demanding: Comprehensive further development of the successful all-round classic iglidur® G. This has been achieved above all with regard to moisture absorption, thermal specifications and consistently improved wear resistance. Only with shock, impact and edge loads, the robustness of iglidur® G could not quite be achieved.

Mechanical properties

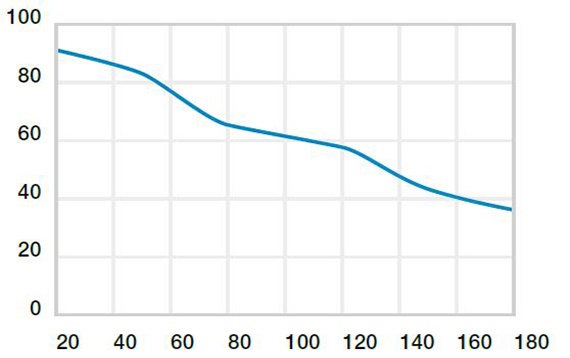

With increasing temperatures, the compressive strength of iglidur® G1 plain bearings decreases. The diagram 02 shows this inverse relationship. With the long-term permitted application temperature of +180°C, the permitted surface pressure still amounts to 40 MPa. The recommended maximum surface pressure is a mechanical material parameter. No conclusions regarding the tribological properties can be drawn from this.

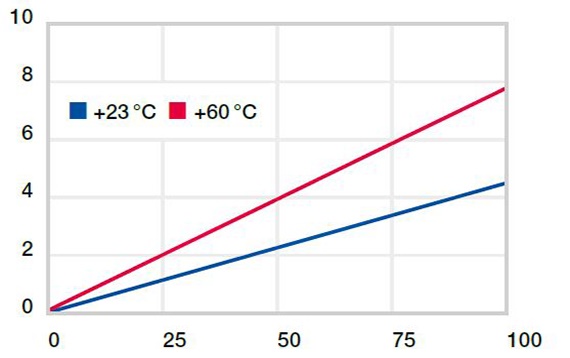

Diagram 03 shows the elastic deformation of iglidur® G1 at radial loads. The plastic deformation is minimal up to a pressure of approximately 100MPa. However, it is also dependent on service time.

Maximum running speed

| m/s | Rotating | Oscillating | linear |

| Long-term | 1,3 | 1,0 | 5,0 |

| Short-term | 2,5 | 1,8 | 6,0 |

Table 02: Maximum surface speeds

Permissible surface speeds

iglidur® G1 has been developed for low to medium surface speeds. The maximum values shown in table 03 can only be achieved at low pressures. At the given speeds, friction can cause a temperature increase to the maximum continuously permissible level. In practice, though, this level is rarely reached due to varying application conditions.| iglidur® G1 | Application temperature |

| Minimum | -40°C |

| Max. long-term | +180°C |

| Maximum, short-term | +220°C |

| In addition secure axially from | +120°C |

Table 03: Temperature limits

Temperature

The ambient temperatures strongly influence the properties of plain bearings. The temperatures prevailing in the bearing system also have an influence on the wear. With increasing temperatures, the wear increases and this effect is significant when temperatures rise over +120°C. For temperatures over 120°C an additional securing of the bearings in the housing is required.

Friction and wear

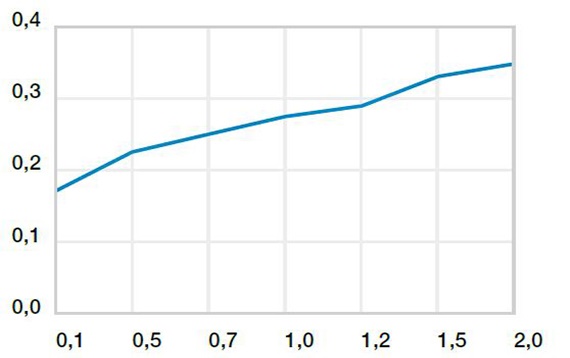

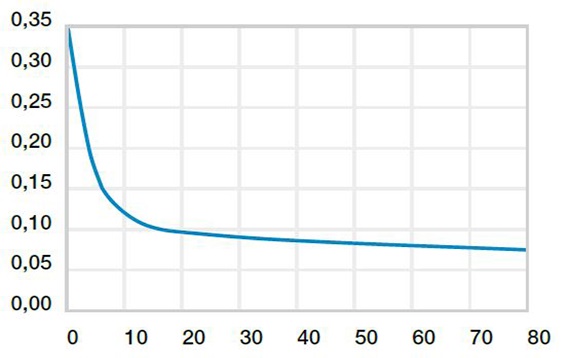

The coefficient of friction μ of a plain bearing among other factors is influenced by the surface speed and the load (diagrams 04 and 05).| iglidur® G1 | Dry | Greases | Oil | Water |

| C. o. f. µ | 0,13 - 0,32 | 0,09 | 0,04 | 0,04 |

Table 04: Coefficient of friction against steel

(Ra = 1 µm, 50 HRC)

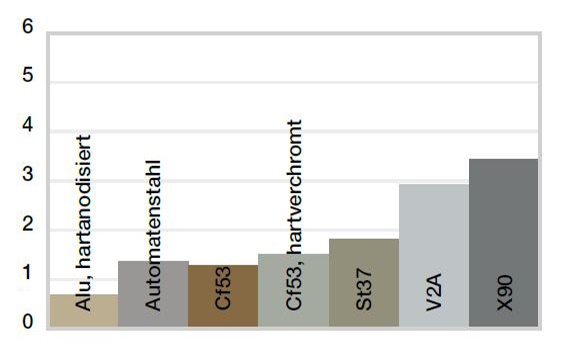

Shaft materials

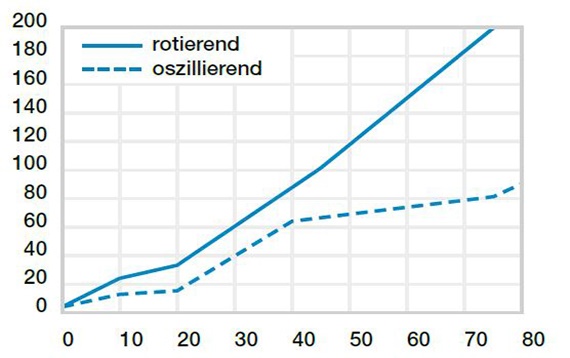

The friction and wear are also dependent, to a large degree, on the shaft material. Shafts that are too smooth, increase both the coefficient of friction and the wear of the bearing. For iglidur® G1 a ground surface with an average surface finish Ra = 0.8 µm is recommended. Diagram 06 shows results of testing different shaft materials with plain bearings made from iglidur® G1. It can be observed that iglidur® G1 achieves good to very good wear results with all shaft materials. The results for stainless steel types are most likely slightly lower. Diagram 07 compares the wear in rotating and pivoting applications. As with many of the iglidur® materials, wear rate is better in pivoting applications.Shaft materials

| Chemicals | Resistance |

| Alcohol | + up to 0 |

| Hydrocarbons | + |

| Greases, oils without additives | + |

| Fuels | + |

| Diluted acids | 0 to - |

| Strong acids | - |

| Diluted alkalines | + |

| Strong alkalines | 0 |

All information given at room temperature [+20°C]

Table 04: Chemical resistance

Moisture absorption

The moisture absorption of iglidur® G1 plain bearings in ambient conditions is approximately 0.2 % weight. The saturation limit in water is 1.7 %weight. This must be taken into account for these types of applications.Radiation resistance

Plain bearings made from iglidur® G1 are resistant up to a radiation intensity of 3 · 10² Gy.UV resistance

iglidur® G1 plain bearings are permanently resistant to UV radiation.Vacuum

In vacuum, any present moisture is released as vapour. Use in vacuum is only possible with dehumidified iglidur® G1 bearings.Electrical properties

| Specific volume resistance | > 109 Ωcm |

| Surface resistance | > 109 Ω |

| Ø d1 [mm] | Housing H7 [mm] | Plain bearing F10 [mm] | Shaft h9 [mm] |

| to 3 | +0,000 +0,010 | +0,006 +0,046 | -0,025 +0,000 |

| > 3 to 6 | +0,000 +0,012 | +0,010 +0,058 | -0,030 +0,000 |

| > 6 to 10 | +0,000 +0,015 | +0,013 +0,071 | -0,036 +0,000 |

| > 10 to 18 | +0,000 +0,018 | +0,016 +0,086 | -0,043 +0,000 |

| > 18 to 30 | +0,000 +0,021 | +0,020 +0,104 | -0,052 +0,000 |

| > 30 to 50 | +0,000 +0,025 | +0,025 +0,125 | -0,062 +0,000 |

| > 50 to 80 | +0,000 +0,030 | +0,030 +0,150 | -0,074 +0,000 |

| > 80 to 120 | +0,000 +0,035 | +0,036 +0,176 | -0,087 +0,000 |

| > 120 to 180 | +0,000 +0,040 | +0,043 +0,203 | +0,000 +0,100 |

Table 05: Important tolerances for plain bearings according to ISO 3547-1 after press-fit