Robust plain bearings for heavy duty use in cultivators in agriculture

Lubrication-free iglidur plain bearings ensure maintenance-free operation and handle high loads

Equipment for ploughing, the so-called grubbers, which were primarily used earlier for weed control. Today, its main use is to loosen up the arable land to mix organic matter and prepare for the next season. The "Karat 9" of the company Lemken GmbH & Co. KG is an intensive cultivator. Lemken uses lubrication-free plastic plain bearings from igus in the bearing points, for which the subsequent lubrication can be eliminated completely.

Profile

- What was needed: iglidur plain bearings

- Requirements: Lubrication-free and maintenance-free as well as robust plain bearings that have to withstand high loads during pivoting movements

- Industry: Agriculture, agricultural machinery

- Success for the customer: Big savings in time and cost, since lubrication is not necessary for the iglidur bearings and they are durable.

Products used

Order a free sample

► iglidur plain bearings sample boxProblem

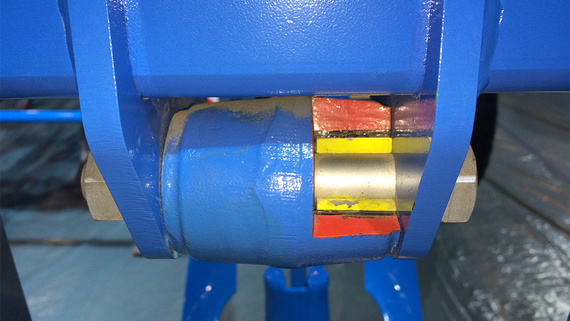

Lemken GmbH und Co. KG is a family-run company that specialises in the production of agricultural machinery for tillage, sowing and plant protection. One of the manufacturer's product areas is equipment for stubble cultivation, so-called cultivators and short disc harrows. These are now used mainly for conservation tillage and cultivation. With the "Karat 9", Lemken offers an intensive cultivator which penetrates between five and 30 centimetres deep into the ground and thus incorporates organic matter perfectly. During use, it is possible that large stones can be in the path of the tractor and its tillage equipment. For this reason, the Karat 9 has overload elements, whereby the tines, which work on the ground in normal operation, automatically dodge backwards and upwards and then automatically return to the working position. The metallic bearing solution used to move the tines had to be lubricated up to 1 hour a day, depending on the size of the cultivator, so that the bearings could do their job properly. If the numerous lubrication points, depending on the working width, were not sufficiently lubricated, the resulting lack of lubrication led to considerable problems with corrosion and greatly increased wear of the bearing point, which ultimately resulted in damage to shafts and housing holes.

Solution

Thanks to the use of lubrication-free igus plastic plain bearings, the overload element is now maintenance-free. The iglidur high-performance materials don't require a subsequent lubrication at all, because self-lubricating solid lubricants are already incorporated in the bearings. This saves valuable time for the farmer. Unlike metallic bearings, where the lubricants cannot be distributed evenly and only the same points on the bearing are always stressed, plain bearings made of plastic can demonstrate their advantages here. The pivoting movements cannot harm them as much and no lubricant can be displaced. Another advantage is the dry operation of the bearings, as no dirt can adhere to them. Together with the high stability of the plain bearings, which easily withstand the high forces in the overload element of the cultivator, this results in significantly increased dependability. In addition, Lemken also saved costs due to the lower procurement costs and the increased service life of the plain bearings.The igus range includes 47 catalogue materials for a wide variety of requirements, including heavy-duty applications such as those found in the agricultural sector. Plain bearings from the all-rounder iglidur G prove themselves in the cultivator Karat 9, by withstanding a compressive strength of 80MPa.

Lars Heier, Head of Marketing Lemken GmbH

Many years of successful cooperation

In 2008, the Karat was the first application by Lemken implemented with lubrication-free iglidur plain bearings. Earlier Lemken used DU bushings in its machines. "All laughed at us about the Karat cultivator in the beginning, because we wanted to use plastic at the bearing point," Lars Heier admits. "Today, the plastic plain bearings have to be replaced only every few years depending on the load, which accounts for, in addition to the lubricant saved, an additional cost advantage." After this pioneering project, numerous other equipment from Lemken were equipped with iglidur bearings. The collaboration between the two companies worked very well in the process: igus tested their own materials very extensively in the in-house test laboratory in Cologne, where various bearing materials are combined with different shaft materials in order to calculate coefficients of friction and wear as precisely as possible. Moreover, Lemken tests the products specifically for their needs at its own site.