Lubrication-free lead screw technology in maintenance-free stands for surgical microscopes

drylin lead screw technology in stands for medical microscopes saves space and runs smoothly

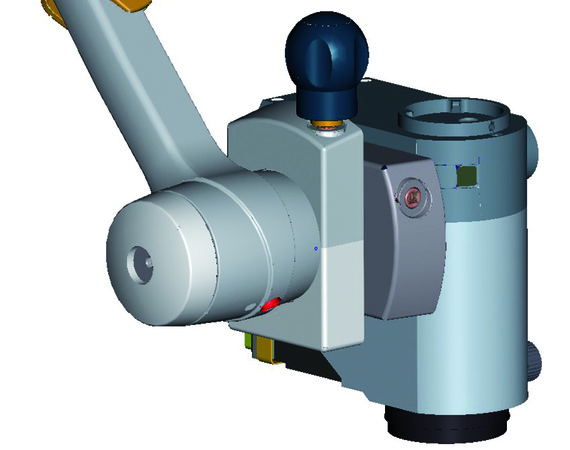

This stand for surgical microscopes from Leica Microsystems can be rotated smoothly. This is made possible by a so-called AB carriage. A new carriage had to be developed for a new stand in the dental sector, as existing systems with two linear guides and a lead screw were too large. The problem was solved by replacing one of the two linear guides with a compact drylin trapezoidal lead screw.Profile

- What was needed: drylin lead screw technology

- Requirements: For the stand of microscopes in the dental sector, the company was looking for a linear guide system that was as compact and lubrication-free as possible.

- Industry: Medical technology

- Success for the customer: The new system consisting of drylin trapezoidal lead screw and lead screw nut is so compact that several cables could be fed through the centre of the AB carriage. This was not possible before. A clearance-free and low-friction movement also ensures maintenance-free and lubrication-free use over the entire service life.

Discover all products for medical technology

Problem

Some of the stands for surgical microscopes from LEICA Microsystems AG are equipped with a so-called "AB carriage". This is located between the support arm and the microscope. It consists of two carriages which are arranged at right angles to each other and have the task of moving the centre of gravity of the microscope including the accessories into the rotary axis so that the microscope can be rotated in a balanced manner. The process is either manual or motorised.For a new tripod for dental applications, there were special design requirements and the desire to find a construction that was as compact as possible. A new AB carriage had to be developed to meet these requirements. This is because existing systems were previously always equipped with two linear guides and a lead screw in each of the A and B carriages and were therefore too large.

Solution

When developing a new solution that can be used for dental applications, one of the two linear guides was replaced by a drylin trapezoidal lead screw (TR 10x2) made of stainless steel with a drylin lead screw nut. The system is so compact that several cables were able to be fed through the centre of the AB carriage. This would not have been possible with the previous concept due to a lack of space. The new concept with just one linear guide and one lead screw has solved this problem. The good operating properties of the material also allow the lead screw to be used both as a guide and as a drive unit. Play-free and low-friction movement ensures maintenance-free and lubrication-free use over the entire service life, whereby lubricants are not permitted in this area anyway.