Maintenance-free plain bearings for reliable tipping device on forklift trucks

iglidur plain bearings enable precise tilting devices for the further processing of fruit without maintenance work

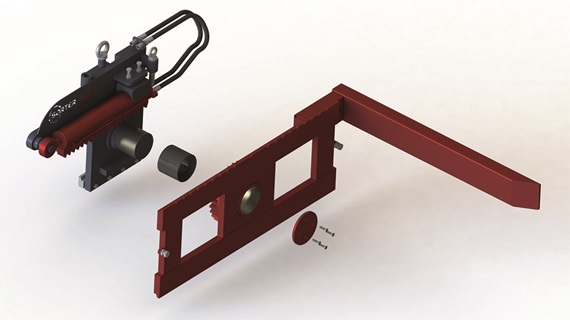

With this tipping device, large collection containers can be emptied with ease. The device is fitted on a forklift truck and can lift, turn and tip out containers weighing up to 600kg. As it is primarily used in the processing of fruit, the bearings used in the device are exposed to moisture. The use of metallic bearings was not possible due to their susceptibility to corrosion and the need for a lubricant. Therefore, only the lubrication-free and maintenance-free iglidur plain bearings were used.Profile

- What was needed: iglidur G plain bearings

- Requirements: Dusty, dirty and damp ambient conditions require resistant and corrosion-free plain bearings, no lubrication wanted, long service life and reliability

- Sector: Mechanical engineering, sorting, packing and palletising solutions

- Success for the customer: igus plain bearings fulfil the requirements for simplicity and reliability, the material performs maintenance-free under difficult environmental conditions and under high weight loads

Problem

The company Sorter in Poland focuses on the design and sale of a range of technologically advanced machine solutions, from sorting machines to packing and palletising solutions.One such solution is a special piece of equipment - a so-called 'tippler', which is mounted on a specially designed forklift truck. As the name suggests, this application performs a 180° tipping movement, which is used to empty the contents of pallet boxes. Such systems are primarily used in the further processing of fruit, for example to safely feed poor quality apples into a collection container. The appliance picks up the fruit in the collection containers and ensures that the fruit can be tipped out without great impact force thanks to the lateral tipping movement.

However, the problem with the design of the tipping device was that there were high demands on the bearings in this system. It was important to ensure high process accuracy and minimise friction. Until now, only regular lubrication of the system was able to guarantee continued machine operation, but this was not desirable.

All individual parts must also be able to withstand high loads. This means that pallet boxes weighing up to 600kg may well have to be turned.

In addition, the system usually works in a dusty, dirty and - due to the processing of fruit - sometimes damp environment. Other systems tended to corrode after only a short time. In addition, the diameter of the main drive shaft must be as large as possible in order to be able to move the load on it at all.

Solution

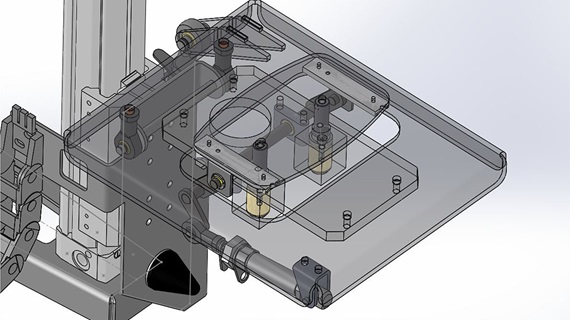

Sorter's design engineers considered various systems during the project planning phase. However, metallic bearings confronted the planners with various problems ranging from susceptibility to corrosion to the need for regular lubrication of the system. After searching for other solutions that were more compatible with the environmental conditions and the high durability requirements, they finally found what they were looking for in bearings, sleeves and guides from igus. Specifically, iglidur G plain bearings of type GSM-110115-110 are used as bearings today. iglidur G is the decathlete among iglidur materials. It performs exceptionally well in all technical disciplines and is the classic all-rounder, especially in terms of its general, mechanical, thermal and tribological properties.

The iglidur plain bearings bring several advantages to the machine concept. Firstly, they solved the lubrication problem. The iglidur G material saves the user further time and costs, as it is completely lubrication and maintenance-free. The bearings are also insensitive to dust and dirt, making them perfect for use in the working environment envisaged by Sorter. However, the solution also fulfils all other requirements that were set during the project planning phase and primarily related to the simplicity and reliability of the design.

In particular, the very good coefficient of friction of the plain bearings plays into the idea of component longevity. The bearings work reliably and allow the system to operate properly, even under high weight loads.