Maintenance-free bearings in bottling plant

drylin and iglidur bearings in bottling plant for dairy products replace susceptible metal bearings

This facility folds, glues, fills, sterilises, and seals milk cartons. Important for use in a dairy: To prevent the milk from being contaminated, bearings and linear guides should be lubricant-free. They must also be resistant to disinfectants and high temperatures. This was achieved with drylin linear guides and iglidur plain bearings.Profile

- What was needed: iglidur plain bearing, drylin R linear bearing

- Requirements: The system's environment is highly corrosive. In addition, light alkaline and acidic solutions, disinfectants and hot water are often used for cleaning.

- Industry: Food industry

- Success for the customer: The new bearing technology made of iglidur plastics is not only completely maintenance and lubrication-free, it is also cheaper to purchase and to operate. After two years of use, the results have been so positive for the customer that the new bearings are also to expected to be used in other machine types.

Problem

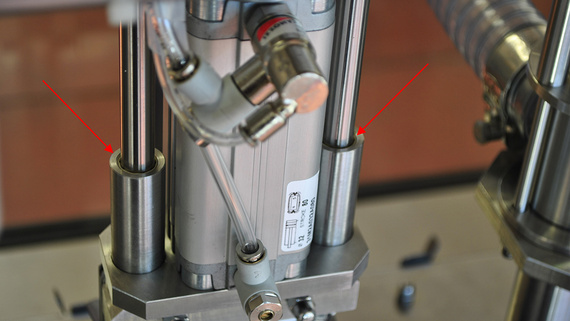

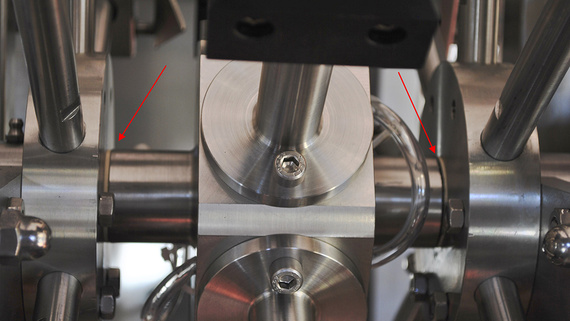

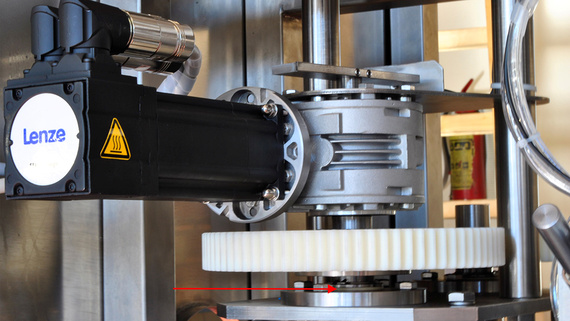

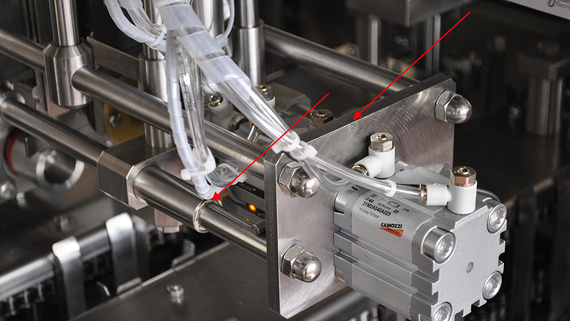

The РР20 is a rotating linear monoblock designed for filling and sealing pasteurised milk and milk drinks in gable top cartons with a polyethylene coating. Several successive actions take place within an automatic cycle. Once the unfolded cardboard blanks have been fed in, the adhesive is applied to the cardboard and the cardboard base is glued on. The machine also automatically places the cap on the milk carton, disinfects it using UV rays, fills the product into the containers and seals them.The existing metal bearings for the various format adjustments and rotating movements in the system were to be replaced by new products, as the high demands of the machine could not be met by the current components.

The environment in the facility is highly corrosive, making metallic components in particular susceptible. Equally problematic is the frequent use of mild alkaline and acidic solutions, disinfectants and hot water for cleaning.

Solution

The various conflicts mentioned in the APP20 for filling and packaging pasteurised milk in the food industry were solved by exclusively using our linear bearings and bushings. They are an alternative to steel bearings and ball sleeves, as they adapt perfectly to the specific working environment.Specifically, sleeve bearings made of the high-performance material iglidur, drylin R linear bearings as well as iglidur double flange bearings were installed, which bring several advantages to the bottling plant. By switching from metal bearings to plastic bearing components, it was possible to find a cost-effective alternative that also saves costs during operation. This eliminates the need to use elements to seal the rotating and moving parts. It was particularly important to the operator to enable economical operation. In addition to the increased reliability of the machine, the new bearings also make cleaning and maintenance easier. It is also important in the food industry that the plastic bearings are completely lubrication-free, which eliminates the risk of contamination of the product.

Two years after the introduction of the new components, the results for the customer are so positive that the iglidur and drylin bearings are also to be used in other machine types, such as in vertical tubular bag machines for liquid products in soft packaging.