Reliable in continuous operation: Hygienic bearings in a high-speed bottling plant

From the cup dispenser to the finished product: iglidur enables a high number of cycles and continuous operation

This bottle-filling system for thin to viscous substances works quickly and precisely thanks to numerous bearing products. Up to 4,080 litres per hour can be filled into up to 14,400 cups, which are then sealed and labelled. In the machine areas of cup dispenser, filling and dosing, lid applicator and sealing as well as labelling and ejection, iglidur bearings and thrust washers as well as drylin shafts are used. This allows a high speed to be realised with almost no maintenance.Profile

- What was needed: iglidur plain bearings and drylin shaft guides

- Requirements: Bearing components were needed that work reliably in continuous operation and are completely lubrication and maintenance-free.

- Industry sector: Filling systems, packaging technology

- Success for the customer: By using iglidur plain bearings with incorporated solid lubricants, no external lubrication is required. They allow a high number of cycles under continuous operation.

Problem

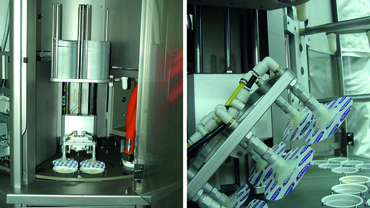

This fully automatic system from machine manufacturer Gujer Engineering GmbH in Kaltbrunn can quickly fill large quantities of viscous to liquid materials into cups such as yoghurt pots. With a cycle time of 1.5 seconds, the machine achieves an output of 1.7 litres, which corresponds to a maximum hourly output 4,080 litres or 14,400 cups. The machine comprises six different stations, from the cup feeder to the ejector, for which plain bearings, shafts and thrust washers are used for different tasks:A cup dispenser, which is equipped for eight different cup sizes, pulls the lowest cup from the magazine by generating a vacuum in order to position it for the filling process. The cups are lifted at the dosing and filling station, after which a rotary valve opens and lets the material into the cups. Before the filled cups can be sealed, a lid dispenser removes the individual lid from a magazine by means of a vacuum and performs a rotary movement to position it precisely on the cup.

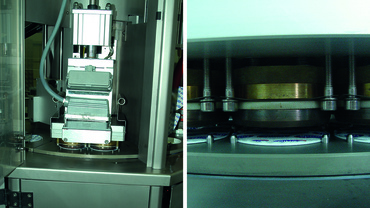

The packaging process is completed with the sealing step. A water-cooled tool holder enables sealing with high-precision positioning with a large usable space and high temperatures of up to 300°C.

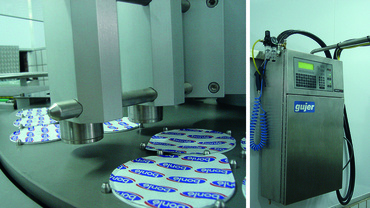

The lids are labelled in the next step. A 2-head inkjet device above the cups is responsible for this process.

Finally, the cups are conveyed upwards in a synchronised manner via a lifting unit. Once here, they are pushed onto a conveyor belt by a pusher and ejected from the process.

Solution

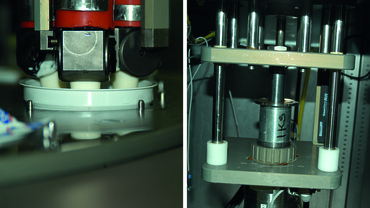

Cup dispenserIn the cup dispenser area, the individual cups are gripped with a vacuum and pulled into the turntable whilst being monitored. To move the grippers, JFM-1818-17 plain bearings are used on an SWM-16 shaft, which enable an impressive rate of 53 cycles per minute.

Dosing unit

In the dosing unit, the containers are first lifted from below using JFM-1618-17 slide bushings and SWM-16 shafts.

For the actuation of the rotary valve, which is positioned above the cup on the machine side and regulates the material output synchronised with the dosing unit, JSM-1012-10 slide bushings are used (shaft: part SWM-10). In addition, iglidur G thrust washers are used on an SWM-16 shaft.

Lid applicator

The lids are removed from the top of the lid dispenser using a vacuum. To rotate the lid gripper downwards and position it precisely above the containers, the manufacturer relies on JFM-1618-17 guide systems on an SWM-16 shaft. They enable high speeds.

Sealing

The sealing station is water-cooled to ensure maximum precision. For high quantities, up to 300°C can be set for sealing the containers. The high machine performance is supported by the JFM-1618-17 plain bearings and SWM-16 shafts, which build up a sealing force of up to 4284N.

Cup labelling

Labelling is carried out using a 2-head inkjet device. The heads can be moved down to the working position manually. This requires JSM-1618-17 plain bearings and SWM-16 shafts.

Ejector

Finally, the lifting unit of the ejector was implemented with the help of JFM-1618-17 plain bearings and SWM-16 shafts, which lift the filled cups to conveyor belt height and then eject them.