Ankle joint prosthesis without corrosion

In this prosthesis, the polymer bearings have to withstand high impact loads and salt water.

This joint for use in prostheses is a new development from Adaptive Sports Ankle Prosthetics. Plain bearings made of iglidur J material and igubal spherical bearings are installed in it. The prosthetic joint was specially designed for use with high abrupt forces, such as those that can occur in sports. Emphasis was placed on the highest possible mobility, but also on special features such as resistance to seawater.Profile

- What was needed: iglidur plain bearings, igubal spherical bearings

- Requirements: Bearings with a very low coefficient of friction were needed, which could be used in or near salt water and were easy to install. They should also be manufactured in accordance with ISO 9001 certified QMS requirements and exceed the test conditions for dynamic and static loads in accordance with ISO 10328.

- Industry: Medicine

- Success for the customer: Due to their material composition, the polymer bearings are extremely wear-resistant, resilient and self-lubricating. The bearings, which require no external lubrication, are therefore also completely maintenance-free.

Problem

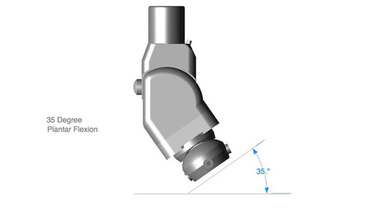

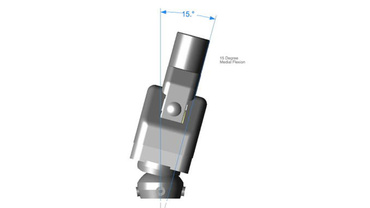

This new development is the only multi-axial ankle joint prosthesis in the world that has been specifically developed for high impact resistance and can sometimes be used in water sports or with high impact loads, such as in equestrian sports, without any problems. The joint drive force of the joint prosthesis component is provided by a spring torsion force, whereby the spring is enclosed in a titanium sleeve.There were high requirements for various spherical and plain bearings that were to be used in the prosthesis. So it needed a shaft bearing that had a very low coefficient of friction. It also had to be corrosion-free when used in or near salt water. It also had to be easy to assemble without the need for fasteners. In addition, it should be manufactured according to ISO 9001 certified QMS requirements and exceed the test conditions for dynamic and static loads according to ISO 10328.

In addition to the shaft bearing, a ball and socket joint is used which can pivot radially during articulation. This should also be corrosion-free, maintain a low coefficient of friction, allow for easy assembly and be CE marked.

Solution

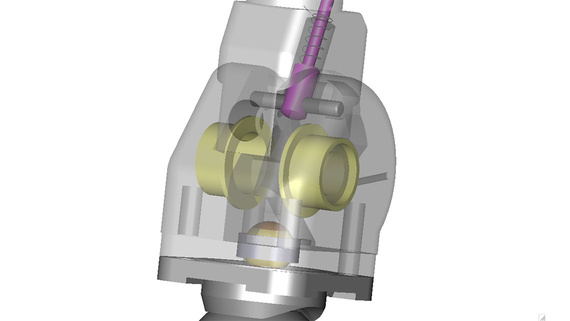

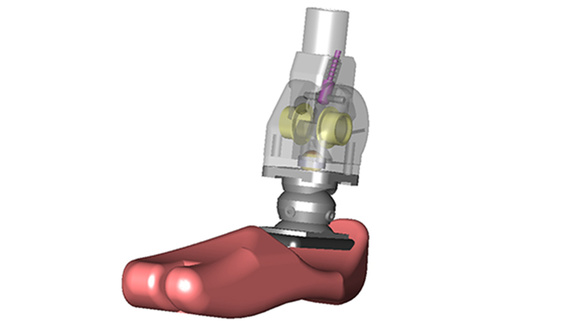

In the newly developed component for ankle joint prostheses, it was decided to use two iglidur J plain bearings as well as one igubal spherical bearing, which allow a high flexibility of the prosthesis.Plain bearings made of the iglidur material are characterised by some special properties, which bring some advantages for this application. Due to their special composition, the polymer bearings are extremely wear-resistant, resilient and self-lubricating. The bearings, which require no external lubrication, are therefore completely maintenance-free.

Equally central to the prosthesis is the use of the igubal spherical bearing, a ball and socket joint that is also designed to pivot radially in use. The polymer spherical bearings, which are economical compared to metal bearings, are the perfect solution for the novelty of the prosthesis, just like the iglidur plain bearings, due to their lightness, simple assembly, dry operation without lubricants or also their corrosion resistance.