Offshore chain OSC

Strongest energy chain - double-protected - flexible

The igus offshore chain OSC is used under the toughest conditions, where safety, a long service life and harsh environmental influences are decisive criteria for the function of the system. The OSC combines the advantages of a plastic energy chain with those of a high-strength pull rope, which is guided in both chain links. Tensile forces are absorbed by the plastic fibre rope and transmitted to the mounting brackets. The interior separation can be modularly adapted to the project and cable package. The e-chain offers a bend radius of 750mm for cables and hoses.Request offshore chain OSC now

Tech up

- Modular system, easy to open if necessary

- All components are individually replaceable

- Interior separation can be individually adapted to project and cable package

- Maximum cable/hose outer diameter up to 80mm or 750mm bend radius

- Resistant to dirt

Cost down

- Turnkey solutions (with plug-in connectors and/or connector housings including electrical testing)

- Integration of i.Sense condition monitoring systems possible for remote scheduled maintenance and operation

- Mounting brackets for easy and fast installation

- Energy chains with 36-month guarantee

Proof

- Permitted operating load of the plastic rope of 187kN

- Operational reliability due to secondary locking tension of all bolted connections possible

- Protects against impact due to robust PU outer body

- Delivery time from 10 weeks

Sustainability

- Recycle integrated energy chain via the igus Chainge program free of charge

- More on the igus contribution to Plastic2Oil

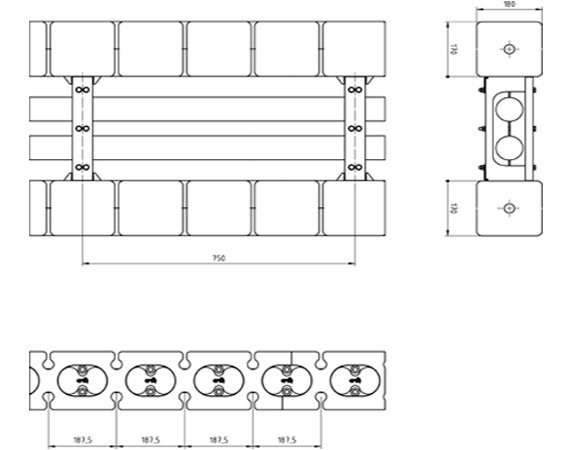

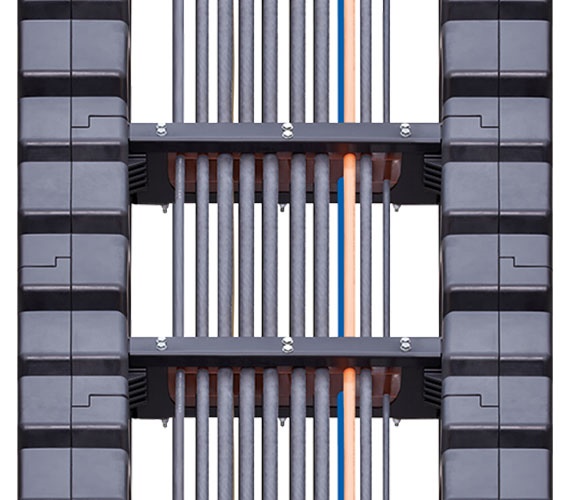

Structure of the offshore chain OCS

Interior separation

The interior separation of the energy chain can be individually adapted to the project and the cables/hoses to be used. The cables are arranged side by side and separated from each other by a PU body (in the form of a comb). The interior separation block is inserted into a steel frame and closed from above with screws and extender crossbars.Chain link

The chain links of the OSC are made of a foamed-on PU material and are therefore shock-resistant. The plastic rope runs inside the chain links and is clamped several times in each chain link. All parts are screwed together and can be double secured if necessary.Plastic fibre rope

The high-strength plastic fibre rope absorbs any tensile forces that occur and transmits them to the mounting brackets. This keeps the cables free from any tensile strain. The pull rope can take up tensile forces up to 187kN.Mounting brackets

The plastic fibre rope ends in the two steel mounting brackets. The strain relief of the cables is also located at this point. The mounting bracket can be screwed to the customer structure using through holes.Product range

| Cable diameter | Max. 80mm |

| Hi [mm] | Max. 80mm |

| Ha [mm] | 180 mm |

| Pitch [mm] | 187,5 / 750 |

| Bend radius [mm] | 750 mm |

| Weight [kg/m] | 40kg/m |

| Work load [kN] | 187kN |

Request a project consultation now

The most exciting projects with the OSC offshore chain

Shore-side power cable management system for floating storage unit in Bahrain

Offshore chain OSC is used in the floating storage unit at the Liquefied Natural Gas (LNG) terminal.

Find out more

Strong cable guidance on a wind farm drilling rig

Offshore chain in what is currently the largest offshore drilling rig with integrated pull ropes

Learn more

The offshore chain OCS can be used in the following industries:

Questions and answers

How can I supply energy in heavy-duty applications safely and reliably? What alternatives are there to service loops and umbilical's?

igus has developed the offshore chain so that cables even with large cross sections and heavy weight can be guided safely in hanging applications. This energy chain is the strongest and most robust energy chain from igus. Specially developed to withstand high cable weights or even wind loads. Due to the installed plastic ropes inside the chain links, the energy chain can absorb tensile loads of up to 187kN.

How does the OSC absorb forces?

The new energy supply system from igus is built around a high-tensile plastic rope that absorbs the tensile forces on the system. The rope is composed of a synthetic plastic fibre and is therefore shatterproof, weather-resistant, flexible and corrosion-free. This enables the e-chain to carry tensile loads of up to 187kN.

igus has developed the offshore chain so that cables even with large cross sections and heavy weight can be guided safely in hanging applications. This energy chain is the strongest and most robust energy chain from igus. Specially developed to withstand high cable weights or even wind loads. Due to the installed plastic ropes inside the chain links, the energy chain can absorb tensile loads of up to 187kN.

How does the OSC absorb forces?

The new energy supply system from igus is built around a high-tensile plastic rope that absorbs the tensile forces on the system. The rope is composed of a synthetic plastic fibre and is therefore shatterproof, weather-resistant, flexible and corrosion-free. This enables the e-chain to carry tensile loads of up to 187kN.

Is it possible to exchange cables in the OSC?

The e-chain is openable from above by loosening the screws on the crossbar. This gives you access to the cable package and you can swap accordingly. Another possibility is to pull the cables lengthwise through the OSC.

How does igus deliver the OSC and how does the installation process work?

The delivery of the OSC chain depends on the chain length. Usually the OSC chain is delivered pre-assembled, with final assembly at the customer's site. Our installation team is happy to take care of the assembly.

How do you prevent chain parts from coming loose and falling down?

All parts of the chain are bolted together, secured with wedge washers and glued. If required, these connections can also be made captive with a cotter pin as a double screw lock.

The e-chain is openable from above by loosening the screws on the crossbar. This gives you access to the cable package and you can swap accordingly. Another possibility is to pull the cables lengthwise through the OSC.

How does igus deliver the OSC and how does the installation process work?

The delivery of the OSC chain depends on the chain length. Usually the OSC chain is delivered pre-assembled, with final assembly at the customer's site. Our installation team is happy to take care of the assembly.

How do you prevent chain parts from coming loose and falling down?

All parts of the chain are bolted together, secured with wedge washers and glued. If required, these connections can also be made captive with a cotter pin as a double screw lock.