Receive long-lasting bearings in special dimensions for ergometers after just 4 days

Maintenance-free plain bearings as a fast and economical solution for ergometers from ergoline GmbH

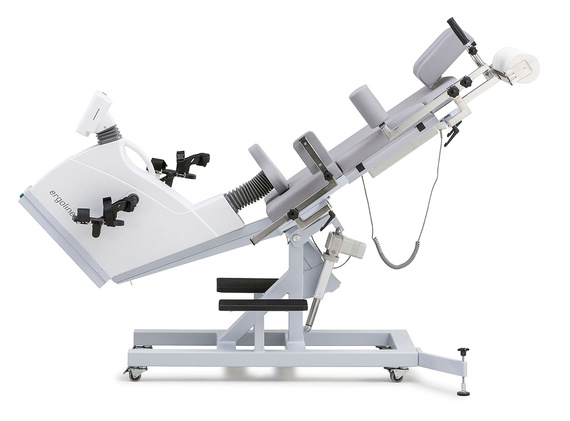

Ergometers are not only popular in gyms or as exercise machines at home - they are also used in medical technology for diagnosing heart diseases. One of its leading manufacturers is ergoline GmbH. In its tilting/recumbent ergometer, it relies on highly wear-resistant and lubrication-free iglidur plastic plain bearings in a special custom dimension. So that the company could quickly start production of its new series, it used the cost-effective FastLine injection moulding service from igus. Within four days, the appropriate tool had been manufactured, injection moulding had started and the first plain bearings were at the customer's premises.Profile

- What was needed: Plain bearing made of iglidur P210

- Requirements: A durable and lubrication-free bearing should be found that can withstand loads such as acceleration and heavy weight. The bearings were custom and required at short notice so that production could start quickly.

- Industry: medical equipment

- Success for the customer: Even with loads, the bearings are extremely wear-resistant. In addition, they are rated high due to their freedom from lubricants and maintenance as well as their long service life. This is why customers have been placing their trust in our motions plastics for 13 years now.

Discover all products for medical technology

Problem

According to the RKI, cardiovascular diseases are the leading cause in Germany for about 40 percent of all deaths. One of the most important examinations for the diagnosis of these diseases and for the control of an initiated therapy is the performance of a stress ECG. Medical ergometers are used for this purpose to ensure replicable stress for the patients. Ergoline GmbH from Bitz near Albstadt is the leading manufacturer of these ergometers. The company has already deployed over 60,000 ergometers worldwide.One of the special devices manufactured by ergoline GmbH is the ergoselect 1200 model. This reclining ergometer was developed for special examination of the heart: dynamic stress echocardiography. The angle of the inclination of the device can be electrically adjusted between 0 and 45°. This allows special ultrasound examinations of the heart during an ergometric stress of the patient.

This adjustment in height and for tilting of the ergometer is exactly what, Dominik Huber, the Head of Design at ergoline, was looking for in a plain bearing. These must be durable and withstand a wide range of loads such as acceleration and high weight. In addition, the high hygiene requirements must be guaranteed by the products. Finally, there was a tight time frame for production. In order to bring the product out, time and money needed to be saved.

Solution

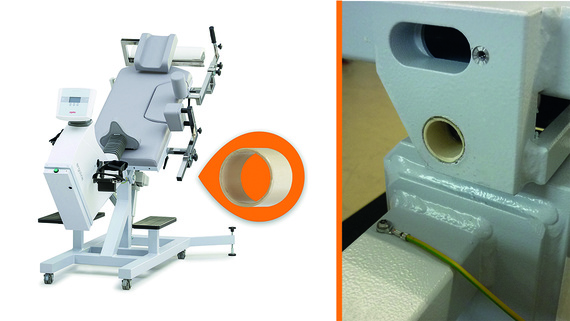

After consultation, the customer decided on plain bearings made of the material iglidur P210, which are ideal for pivoting movements on various shaft materials. Especially for loads up to 20MPa, it is extremely wear-resistant, and it is also well suited for edge loads. By dispensing with external lubricants, the plastic bearing also meets the highest hygiene requirements in medical technology. In the ergometer application, iglidur P210 has the maximum service life, which is also shown by the service life calculation that igus offers with the calculator.As the bearings selected from the catalogue had too much bearing clearance, another solution was required for the start of volume production.

Here we offered the FastLine service to the customer. Due to investment in our production line for custom parts with CNC technology, we were able to produce plain bearings for ergoline in the required shape in a very short time. It took just four days from order to delivery. And the price was also much lower than the customer expected.

The bearings proved themselves from both an economical and a technical perspective. The polymer bearings are lightweight, rust-free and insensitive to dust and dirt.

The ergoline GmbH has been relying on our motion plastics for 13 years and has already installed thousands of plastic bearings in its equipment. And in other ergometer models, too, the specialist relies on our other products in addition to the plain bearings. For instance, using drylin W linear guides for the seat adjustment in the sitting ergometer, ergoselect 600.

Dominik Huber, Head of Design at Ergoline GmbH