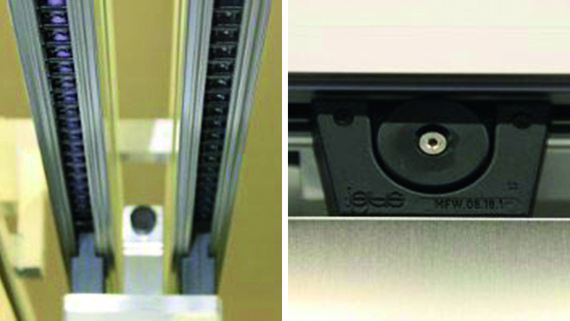

Maintenance-free cable guide for sliding control panel

Compact, quiet, maintenance-free: micro flizz e-chains prove themselves in packaging machines for ice cream

This visit to the trade show was worthwhile for the specialist machine builder. In the past, the company had designed and built its sliding control panels itself. Then they discovered a special energy chain solution called micro flizz, which is compact, quiet and maintenance-free, and which has since proven itself functionally reliable in highly complex packaging machines for ice cream. This saves at least a week of design time, allowing the company to concentrate on its actual task, machine designing.Profile

- What was needed: micro flizz energy chain system, chainflex cables

- Requirements: the packaging system operates six days a week with three shifts a day and had to function absolutely reliably, be durable and also fit in well with the overall appearance of the system.

- Industry: food, packaging systems

- Success for the customer: the micro flizz is particularly compact, quiet and maintenance-free. The design reduces the application of force and minimises friction and wear on the energy chain. The space-saving system is closed at the top so offers protection against dirt and dust.

Problem

Wilhelm Fischer Spezialmaschinenfabrik GmbH designs, constructs and produces complete lines for the packaging industry, including electronic control. The focus here is on customised complete solutions for the use of carton packaging.The prototype of a packaging machine for the premium ice cream "Magnum Temptation" from Langnese was to ensure precise folding of the carton for the premium product. This is done in a special part of the overall system, the so-called erector, which prepares the carton for the subsequent processes, such as the heating and pressing stations. As this is primary packaging, it must not be glued so no adhesive residues get into the packaging.

Wilhelm Fischer was particularly careful when selecting the components to be used due to the high demands of the system. Since the entire packaging line runs six days a week and three shifts a day, it has to function absolutely reliably, be durable and also fit in well with the overall appearance of the system.

A sliding control panel is used along the entire length of the erector. This allows the respective machine operator to follow all stations of the cutting process at any time, stop the system if necessary and intervene. All operating and programming elements are integrated into the panel, which can always be moved to the exact place where it is needed. For the mobile panel's guidance system, a cable solution was sought for the various data and power cables.

Solution

Whereas the sliding control panel used to be built by the operator with the help of a rail guide system in combination with an energy chain, today the so-called micro flizz system is used. The very compact, quiet and maintenance-free energy supply system provides energy to a movable consumer by means of a rolling or sliding carriage running underneath. It runs in a guide channel made of aluminium, which separates the upper run and the lower run of the energy chain to save weight. The low force minimises friction and wear. The space-saving system is closed at the top so offers protection against dirt and dust.The panel is suspended on a total of four rollers. They are so strong that the entire control element remains locked to the machine and does not wobble. As this is purely a machine operation, no high technical requirements are placed on the solution. It is only used for adjustment and maintenance work.

Wilhelm Fischer became aware of the system some time ago when he visited the "Motek" trade show. After the machine specialist realised that it completely covered the requirements for the control panel, the system was ordered with all cables fully harnessed, was installed and there has been no problems since then.

The cables are chainflex control, bus and data cables that are completely protected and not exposed to any mechanical influences. Ordered fully harnessed, the machine builder now saves at least a week of design time.

Ice cream production is now operating at full speed, so that a second packaging line is now in use. The micro flizz is used here too.

Rupert Greiter, CEO of Wilhelm Fischer Spezialmaschinenfabrik GmbH