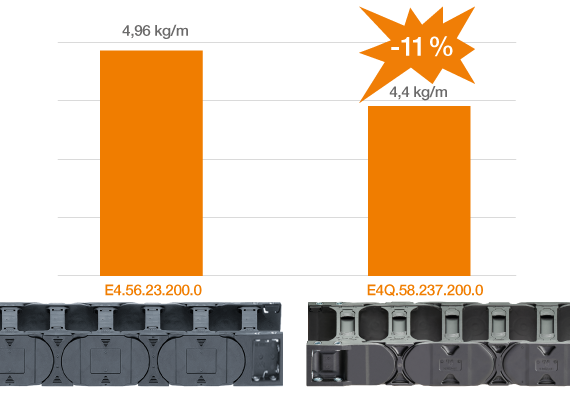

Weight-saving energy chain systems

It is evident that the lower weight of the moving components is good for the overall performance of the machine. Less weight means lighter moving masses, heavier filling and also reduction of the drive power needed, which in turn leads to lower energy costs. Save weight in your application with the help of better energy chain systems.

Saving weight with igus energy chains in the milling machine for bicyles from SHW Werkzeugmaschinen GmbH

In the new development of the PowerForce 8, a total of 15 energy chains from igus were used in all travel axes, the lifting cabin and the tool changer. By using igus energy chains, SHW Werkzeugmaschinen GmbH was able to reduce the weight by 40%.Learn more

Recommended weight-saving energy chains

Up to 10% less weight

To the product

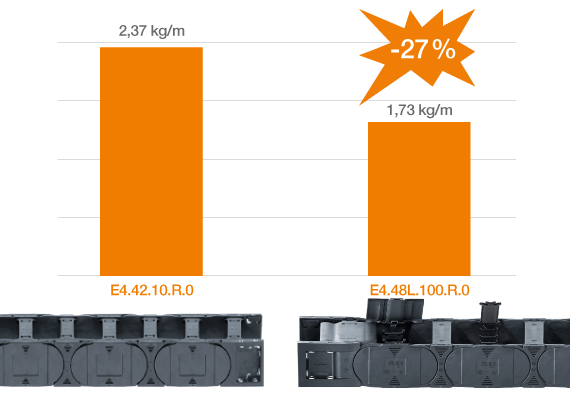

Up to 27% less weight

To the product

Up to 30% less weight

To the product

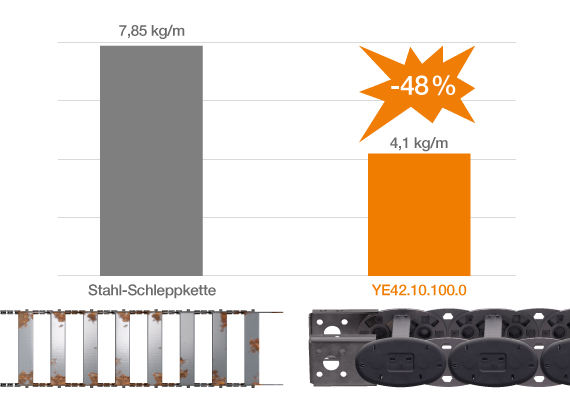

Up to 48% less weight

To the product

Expert tips

Valuable tips on how to plan your own energy chain project for a wide variety of applications, optimise the chain, and design it for the longest possible service life. These tips should never be considered a substitute for advice from igus® experts. Our technical consultants in the field and in the office will be happy to support you - a.o. during measurement, design, installation and commissioning on site.Heavy components lower the payload

Solutions for telescopic work platforms

Customers rely on energy chains

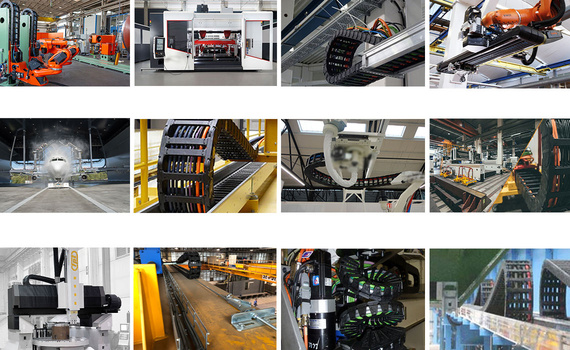

Discover more energy chain application examples

You might also be interested in

Cost down

Cost down now