Technical data:

- What was needed: A lead screw drive that is fitted on the outside of the vehicle, which is exposed to water and dirt and nevertheless functions perfectly

- Requirements: No maintenance needed, corrosion-free, resistant to spray water, high helix thread with maximum efficiency, resistant in salt spray test, special design of the nut with clip function on the outer diameter, lightweight

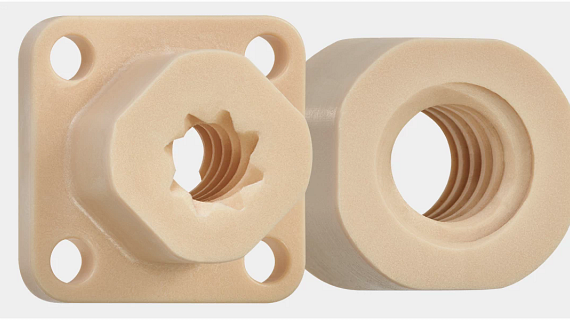

- Products used: dryspin® lead screw nut made of iglidur® J in special design with clip function for easy assembly, dryspin® high helix lead screw with thread DS6.35X25.4. Material 1.430

- Success for the customer: Very short development time as special lead screw and lead screw nut are matched to each other at igus. Outstanding emergency operating characteristics thanks to solid lubricants integrated into the iglidur J plastic nut.

To the automatic front spoiler

On a level road, the spoiler extends downwards at a speed of 60 km/h or more. It guides the airflow over the vehicle in such a way that no uncontrolled turbulence occurs underneath the vehicle. In the case of a pick-up truck or SUV, this means a considerable improvement of the aerodynamics and therefore less fuel consumption. If the speed drops below 60 km/h or the road suddenly becomes uneven, the front spoiler is pulled upwards.In the development phase and during validation, the lead screw drive was exposed to unusual kinds of stress. Test runs in Alaska in winter at temperatures down to -40°C, salt spray tests to test resistance to corrosion, also severe stress due to slush and spray water. Then in summer, the heat and dust in the Nevada deserts The lead screws and nuts from igus® withstood all of this, without any maintenance or additional lubrication.

What is the difference between dryspin® lead screw drives and those with standard geometries?

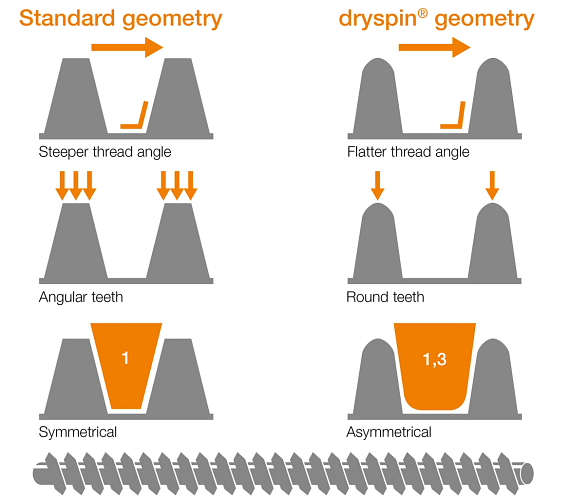

High efficiency and low wear

The patented dryspin high helix thread technology was developed by igus in 2013 and offers numerous advantages compared to conventional high helix threads. Due to the flat thread angle, it converts the exerted power efficiently into a translational movement. With properties and shapes matching the polymer nut and lead screw, dryspin thereby provides an even longer service life and more efficiency for high helix threads. Due to the rounded tooth geometry, the contact area between lead screw and nut is reduced, and the lead systems operate quietly and without vibration under load.

The larger spaces between the individual dryspin threads result in a higher share (factor 1.3) of tribologically optimised polymer in the threads. More wear-resistant material and higher levels of efficiency are crucial for a service life that is up to five times longer compared to conventional high helix threads.

Take advantage of our machining service - we manufacture ready-to-fit lead screws based on your requirements. For this, use our lead screw configurator or send us a drawing. We will then provide a quotation.

The larger spaces between the individual dryspin threads result in a higher share (factor 1.3) of tribologically optimised polymer in the threads. More wear-resistant material and higher levels of efficiency are crucial for a service life that is up to five times longer compared to conventional high helix threads.

Take advantage of our machining service - we manufacture ready-to-fit lead screws based on your requirements. For this, use our lead screw configurator or send us a drawing. We will then provide a quotation.

Further details:

Free dryspin® lead screw sample

Own lead screw drive with bundled information

- If you want to test the dryspin technology, you can request a free sample of a lead screw drive here.

- All the important information and advantages are briefly summarised for you again on the sample sleeve.

- You can get in touch with us quickly

Request sample here

Configure easily online

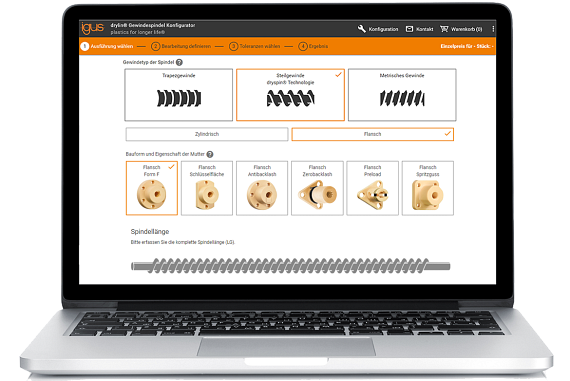

Customer-specific solutions configurable online

The expert can quickly help engineers find the right lead screw system part for their application and will also predict service life.

The configurator enables engineers to quickly find the right lead screw and machine the pins from both sides. The application generates a dimensioned drawing of the configuration for you.

The configurator enables engineers to quickly find the right lead screw and machine the pins from both sides. The application generates a dimensioned drawing of the configuration for you.

Configure here

Get in touch directly

Fast processes and short delivery times

Our experts do everything to ensure that you receive your perfect solution within a very short time. 4,150 employees in Germany and 35 international subsidiaries and offices in more than 80 countries guarantee fast processes and speedy delivery all over the world. For prototypes and samples as well.

Contact us here

Other drylin® lead screw technology application examples:

| Beverages industry | Wood industry | Camera technology | Food industry | Medical technology | Model making |

| Furniture & industrial design | Robots | Solar power technology | Textile industry | Packaging industry | and many more

dryspin® lead screw drives in vehicles

Five reasons why dryspin® technology is used in automobiles

With the dryspin lead screw technology, it is easy to design individual lead screw nuts and lead screws exactly according to the wishes of the customer. Our experts will be happy to help you choose the right lead screw drive and will ensure that deliver times are short. The wide choice of materials and complete absence of a need for lubrication or maintenance mean that the lead screw drives can be used in almost any area of the automotive industry. They are ideal for small installation spaces and operate almost silently even when the drive torque is low. Uncomplicated integration into your vehicle or assembly is also an aspect that speaks in favour of the cost-effective alternative to conventional lead screw drives made of metal.To the overview page