Bearing technology for actuators and control elements

Easy lifting, lowering and adjustment with maintenance-free plastic components

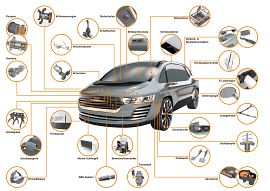

The automotive industry is responding to the increasing desire for comfort with more electrification in the vehicle. This also increases the number of actuators and control elements - for example in longitudinal, height and tilt adjustments of seats, in locking systems, window lifters, sliding roofs, rear view cameras or lighting systems. For these applications, we have plain bearings, lead screws and lead screw nuts as well as gears and gearing components in our product range. We would be happy to assist you in your selection.Requirements for products in actuators:

- No NVH

- High number of cycles > 1 million

- Resistance to lubricants

Advantages of igus bearing technology:

- Cost advantage compared to metallic rolled bearings and ball bearings

- Up to 80% weight savings

- Quiet operation

- Operates dry without lubrication

- Design freedom in injection moulding

Suitable products

iglidur J

Extremely low friction values in dry operation, very good wear resistance at medium temperaturesLearn more

iglidur H4

The automotive standard with high resistance to chemicals and temperatures between -40°C to +200°CLearn more

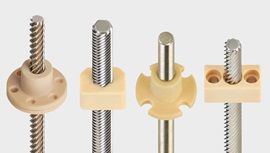

Lead screw technology

Maintenance-free linear technology with up to 30% longer service lifeLearn more

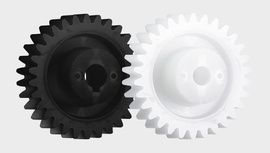

Gears

Lubrication-free, up to 4 times more wear-resistant than gears made of comparable plasticsLearn more

Further areas of application

Inside and outside: our dry-tech polymer bearing technology shows its advantages in many places in the car.Watch now

Go back to overview

To the introductory page with information on the advantages of our bearings and special servicesGo to overview