Technical data:

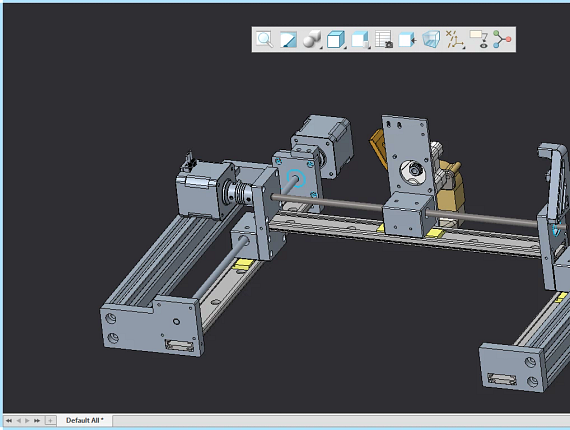

- What was needed: A precise and quiet 3D printer that meets the conditions for "Made in India"

- Requirements: 100% freedom from lubrication and maintenance, precise, quiet and vibration-free operation, smooth dry operation

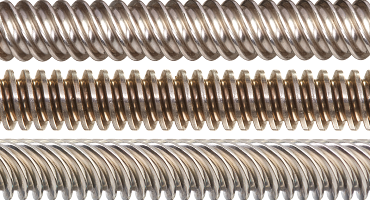

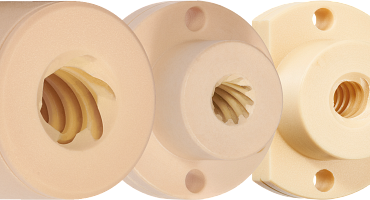

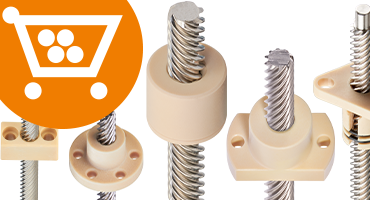

- Products used: dryspin® lead screws and lead screw nuts, iglidur® plastic plain bearings, energy chains for medium loads E2, also drylin® T rail guide, drylin® N low profile guides and drylin® W profile guides with corresponding carriages and pillow block bearings

- Success for the customer: Fabforge Innovations is a 3D printer manufacturer based in South India with operations nationwide. It used to use linear rails from other manufacturers, but to meet the "Make in India" conditions, Fabforge Innovations changed the design and used igus® products.

Do you need more information? Contact us here

Problem

Fabforge Innovations, an Indian company, develops 3D printers. To achieve "Make in India", components must be sourced from India. In the past, the linear systems and plain bearings used were sourced from manufacturers that were not exclusively from India. This, of course, included lubrication, maintenance and problematic runs. Also, the parts must have a certain pretension and have different colours.Solution

For the 3D printer, the engineers use numerous components from igus® India that enable lubrication-free, low-maintenance, precise and quiet dry operation: dryspin® lead screws and lead screw nuts, iglidur® plastic plain bearings, E2 energy chains for medium loads, also drylin® T rail guides, drylin® N low profile guides and drylin® W profile guides with appropriate carriages and pillow block bearings.Products used

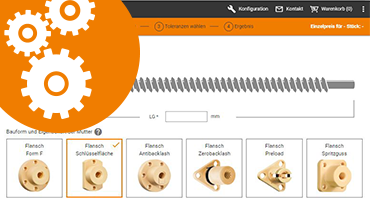

Do you have questions about drylin® lead screw technology?

Our expert Thorben Hendricks will answer all your questions about drylin lead screw technology. Just fill out the contact form and we will take care of your issue. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample

Request expert support here