Technical data:

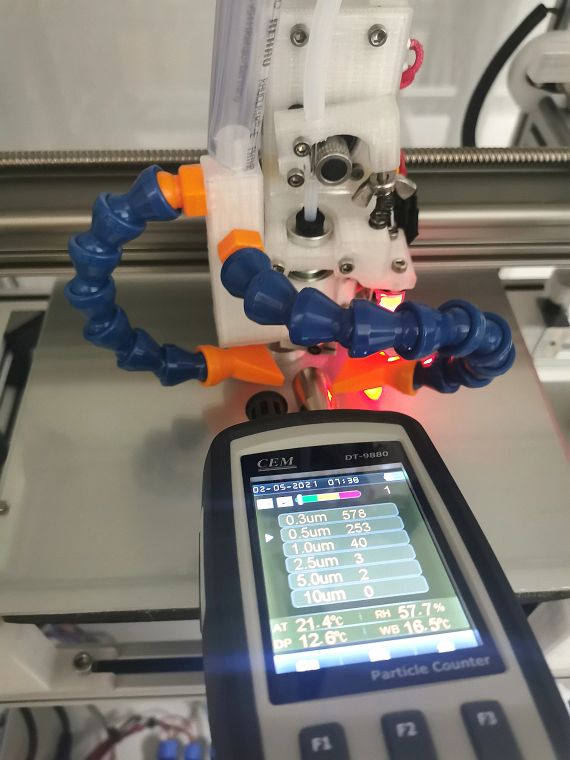

- What was needed: A precise, reliable cleanroom 3D printer for processing thermoplastics

- Requirements: No lubrication or maintenance, long service life, suitable for clean rooms, no abrasion, cost-efficient

- Products used: Simple encapsulated stepper motors with coupled dryspin® high helix lead screws and flange lead screw nuts with spanner flats made of iglidur® A180, encapsulated stepper motors with coupled trapezoidal lead screws and flange lead screw nuts made of iglidur® A180, igus WSX double rail, drylin® W single rails, drylin® R aluminium shafts, igubal® pillow blocks and flanged bearings, xiros® radial deep groove ball bearings

- Success for the customer: drylin® bearings with replaceable liners provided design freedom on all linear guides. This significantly accelerated the VIVECube – Clean Precision design process. The liners effectively prevent unwanted particle release while providing process stability. There were other advantages from using suitable rail and shaft guides for system implementation.

High helix and trapezoidal lead screws with high efficiency for all drive axes were the ultimate solution to the problem of VIVECube – Clean Precision cleanroom capability. It was the only suitable solution for low-abrasion linear drives that was also cost-effective.

Go to application

VIVECube – Clean Precision cleanroom 3D printer

Application description. What is the function of the application? Where is the application used?

VIVE-MedTech GmbH develops and manufactures customisable, user- focused medical devices. The product range extends from surgical instruments and catheters to artificial lungs for use during temporary lung replacement therapy. The products must meet high standards of safety and performance - especially with respect to cleanliness and purity from foreign substances. Here, VIVE-MedTech uses a 3D printing production, developed in-house, in the cleanroom: The VIVECube - Clean Precision is a precise, reliable cleanroom 3D printer for processing thermoplastics.

What are the usage/environmental conditions at the end user's location? What challenges did you have to overcome to adapt to those conditions?

Medical device production places its own requirements on the purity and cleanliness of the production materials and auxiliary materials used. The machines must operate without lubrication as far as is technically possible while remaining reliable and durable. Special challenges arose in linear drive train implementation and material selection.

What requirements did the bearings have to meet?

It is especially important that our production equipment's bearings are low-abrasion and durable. In order to control the unavoidable residual abrasion, however, bearings and drive elements must be made of materials that are largely harmless. Of course, all components had to remain cost-effective and reasonably available.

Which igus solutions are used?

In the VIVECube - Clean and precise polymer bearings are used at various points.

X-axis plain bearings: An igus WSX double rail is used here as "bridge axis". This offers very good flexiiblity and stiffness for our application. A bespoke designed carriage with drylin® fixed and floating bearings and liners made of iglidur® A180 runs on the rail.

Y-axis plain bearings: drylin® W single rails run parallel on both sides of the bridge axis. On each of them, a bespoke-designed carriage with drylin® fixed and floating bearings and iglidur® A180 liners are also used.

Z-axis plain bearings: Four parallel drylin® R aluminium shafts are used for robust printing platform guidance. The printing platform is guided with a bespoke-designed carriage featuring drylin® fixed and floating bearings and iglidur® A180 liners on the shafts.

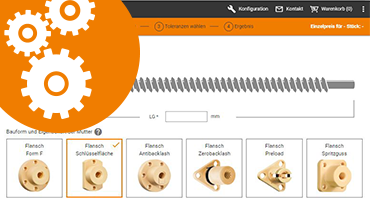

X/Y-drive train: Simple encapsulated stepper motors with coupled dryspin® high helix lead screws are used on the bridge axis in the x-direction and on both parallel individual rails in the y-direction. The X-axis carriage and both Y-axis parallel carriages are then driven with matching dryspin® flanged lead screw nuts with spanner flats made of iglidur® A180. The high helix lead screws are each guided at the end with igubal® pillow block and fixed flange bearings.

Z-drive train: Two synchronously operating stepper motors with coupled trapezoidal lead screws are used to raise and lower the printing platform. The printing platform is driven with a flange lead screw nut made of iglidur® A180.

Print head filament feed: The print head's filament feed uses a xiros® radial deep groove ball bearing made of xirodur B180 as a pressure element.

Products used

drylin® W WSX double rail

drylin® W single rail

Do you have questions about drylin® lead screw technology?

Our expert Thorben Hendricks will answer all your questions about drylin lead screw technology. Just fill out the contact form, and we will take care of your issue. We are looking forward to your message!► Request contact online

► Make an appointment

► Expert support upon request by phone or with the video chat function

► Order a free sample