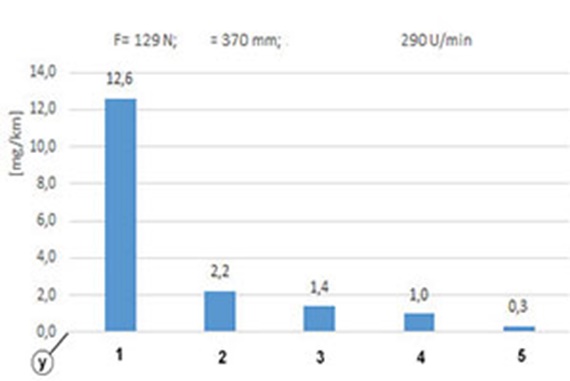

iglidur® tribo-filament and iglidur® bar stock in comparison

In the test, a drylin® SHT lead screw linear system was set up vertically and the drive nut was subjected to a load of 129N (Image 1). The stroke length amounted to 370mm and the spindle speed to 290rpm. A dryspin® DST high-helix lead screw was used, which is specially tailored to the lubrication-free iglidur® high-performance polymers and thus guarantees a longer service life.

Wear-resistant drive nut

Y = Wear rate [mg/km]

Stroke = 370 mm

Lead screw speed = 290 rev/min

1 = ABS printed

2 = iglidur® i180 printed

3 = iglidur® J260 printed

4 = iglidur® R bar stock

5 = iglidur® J bar stock

Stroke = 370 mm

Lead screw speed = 290 rev/min

1 = ABS printed

2 = iglidur® i180 printed

3 = iglidur® J260 printed

4 = iglidur® R bar stock

5 = iglidur® J bar stock