Automation of worm breeding with reliable bearing and cable technology

Self-developed robots and driverless transport vehicle automate worm farming.

The Langhoff family breeds giant red worms that are used by anglers, for example, as feed worms for animals, for hunting or as a natural fertiliser producer for gardens and greenhouses. For around ten years, Martin Langhoff has been developing his own machines, which facilitate the everyday work of the family business by improving the breeding process and making it more effective. For use in areas where there is water, soil and dirt, the robust components from igus have become a reliable partner in this time.Profile

- What was needed: drylin® ZLW toothed belt axes, E4 e-chain®, E6 e-chain®, igubal® ESTM pillow block bearing, igus® stepper motors

- Requirements: Wear-resistant and reliable components for cable guidance and bearing points that can be used in the presence of dirt and moisture

- Industry: agriculture

- Success for the customer: drylin toothed belt axes pull the 120 kg containers effortlessly, are exceptionally light, require only low power for operation and are insensitive to shocks and dirt, igubal pillow block bearings withstand the high radial loads, are self-lubricating and thus maintenance-free in use, the E4 and E6 e-chains guide all cables safely and easily cope with the sometimes fast travel speeds of the system

Discover all products for the agricultural industry

Problem

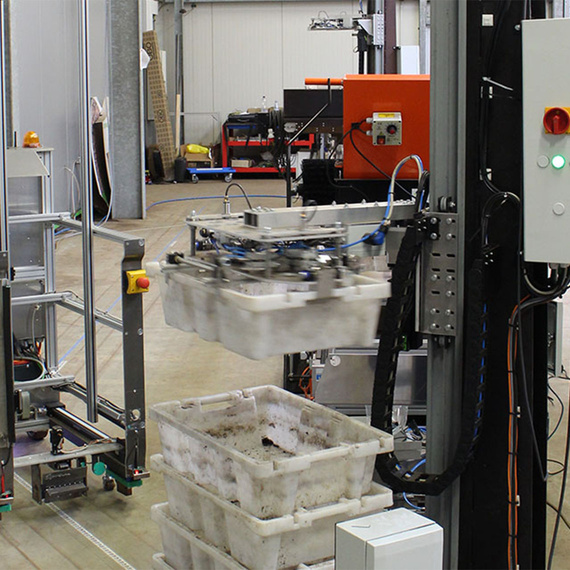

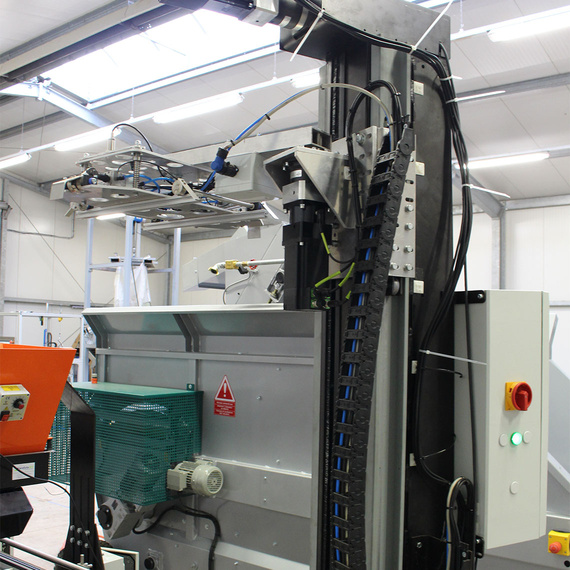

The Langhoff family breeds giant red worms that are used by anglers as feed for the fish. To fully automate the feeding and watering process, Martin Langhoff, owner of Superwurm, developed a completely new machine. This includes two robots, a conveyor belt and an automated guided vehicle (AGV). With the system, feeding and irrigation can be carried out around the clock, even when staff are not present.The AGV picks up the euro-containers filled with soil and worms in stacks from the warehouse and takes them to the new feeding and watering facility. Arriving at the new feeding and watering facility, the AGV moves the containers to the first robot, which places them one by one from the trolley stack onto a conveyor belt. On the conveyor belt, the containers are then automatically watered and fodder is strewn on the soil. At the other end of the assembly line, a second robot lifts the watered and fed containers off the conveyor belt and onto a trolley, which the AGV picks up and returns to the warehouse.

For the system, Langhoff was looking for components that would function reliably and permanently under difficult operating conditions with dirt, soil and moisture, as the machine was designed for 24-hour continuous operation. In addition, they had to function without lubrication so that worms and soil remained uncontaminated. Soil and moisture contaminate bearing points particularly in this machine.

Solution

Today, two synchronously driven and parallel drylin® ZLW toothed belt axes are used in the AGV, which pull the container stacks on a wheeled carriage into the transport vehicle. For this purpose, toothed belt axes with stepper motors were necessary, which can pull containers weighing 120 kg. This complete system is very light, requires only low power to operate and is resistant to shock and dirt.For the movement of the toothed belt axes, the cables are guided by means of an E6 e-chain® . Their service life is increased and they are protected from external influences. When the containers are completely retracted into the AGV, a barrier closes via an igus® stepper motor to provide additional safety during transport.

For the opening and closing of the robot gripper shafts are supported by igubal® ESTM pillow block bearings. They withstand high radial loads, are self-lubricating and maintenance-free. In order to guide the cables safely during the fast movements of the robot and to ensure long-lasting cables, an E4 series energy chain is used. In addition, igus® stepper motors with gearboxes are used so that the gripper can move the containers onto the conveyor belt.

In the meantime, the drylin® R quad blocks with solid plastic bearings and the E4 e-chains® have been in continuous operation successfully for ten years now - without any maintenance or cleaning being necessary.