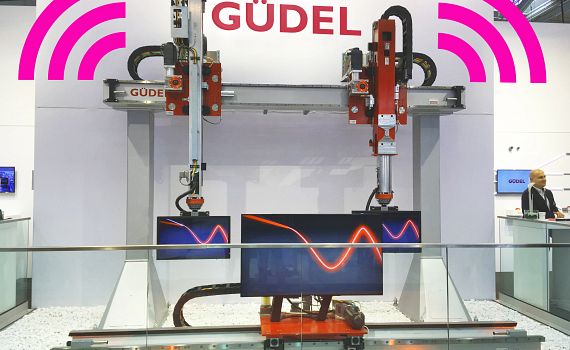

Güdel relies on condition monitoring for the energy chains on linear robots

No surprises thanks to the measurement of movement, temperature and wear in real time.

More and more manufacturers of machines and systems are offering solutions with their own condition monitoring tools. Customers of the Swiss automation expert Güdel, for example, can monitor their linear robot on a central platform - the Güdel Condition Monitoring Computer. For example, the cloud evaluates data from the guide rollers on the linear robots. Güdel also relies on condition monitoring for the energy chains and installs our "i.Sense EC.W" sensors on its linear robots. In this way, the movement and wear of the four energy chains can be measured and maintenance measures can be planned in advance.Profile

- What was needed: Condition monitoring sensors EC.W for real-time condition monitoring (measurement of movement, temperature, wear)

- Requirements: Simple integration of the sensors into Güdel's existing condition monitoring system; output of predictive maintenance recommendations for the e-chains

- Industry: Automation technology; material handling

- Success for the customer: The sensors for the e-chains send the measured values to Güdel's condition monitoring computer and are perfectly integrated into the system architecture. The AI uses extensive data and knowledge from our in-house laboratory to recommend maintenance measures at the right time.

Request smart plastics

Products used

Order a free sample

► i.Sense EC.W (e-chain + sensors)The challenge

The Swiss company Güdel develops and constructs linear technology and drive systems such as traversing axes or linear robots for logistical processes in a wide variety of industrial sectors. What counts here are absolutely reliable systems and a high level of predictability.For this reason, Güdel also offers its own condition monitoring system, which monitors the guide rollers of the linear robots, sends data to a cloud and provides the user with valuable information in real time.

For the energy chains that the automation expert installs in its linear robots, sensors should also be installed that directly record data such as movement parameters and other status information and feed them into the same cloud. The main focus was to find sensors for the energy chains that could be seamlessly integrated into the data infrastructure of the existing condition monitoring system.

Solution

The automation specialist Güdel uses our sensor technology i.Sense EC.W for the energy chains installed on its linear robots. These measure the movement, temperature and wear of the four e-chains used and send the measured values via the icom data concentrator to Güdel's condition monitoring computer. This means that Güdel can offer its customers integrated condition monitoring that can be viewed via a central platform. With the tool, the user can quickly and clearly see the condition of the energy chains and rollers used during operation.Since the i.Sense EC.W sensors are connected to the igus cloud, the data from the energy chains are also evaluated using AI and machine learning. Extensive data and findings from our in-house laboratory are used. The solution automatically recommends maintenance measures to the day. Maintenance can be planned and failures during operation are avoided.

Find out more about the i.Sense EC.W service life sensor