smart bearing technology

smart plastics news 2023 ...

... experience now all smart plastics 2023 new products like the breakage monitoring for robot chains i.Sense TR.B or for the first time the new smart all-round service superwise right here:Industry 4.0: 2023 smart plastics News - overview

smart plain bearing technology

iglidur isense plain bearing

- Avoid sudden failures

- Detect and monitor maintenance requirements via remote diagnostics

- Available as an FDA-compliant all-rounder

- High wear resistance

- Resistance to dust and dirt

Go to smart plain bearings

A defective plain bearing can ruin the day, not only for farmers but for any machine operator.

Smart plain bearings are great for especially sensitive or hard-to-reach spots on a machine, since they allow the bearing's condition to be assessed at any time.

Smart plain bearings are great for especially sensitive or hard-to-reach spots on a machine, since they allow the bearing's condition to be assessed at any time.

3D printed smart plain bearings

- Wear-resistant parts with sensors produced by means of multi-material 3D printing

- Warning when wear limit is reached

- Warning before overload occurs ► Avoid damage

- Predictable service life

- No minimum order quantity

- No lubrication necessary

3D i.sense - 3D printing with integrated sensors

Test & creation of the 3D printing i.Sense bearing

Video contents:- The bearing is printed from 2 materials: igus tribo filament (white) and an especially conductive material (black)

- The wear of the bearing is measured on the black material.

- Printed with a multi-material printer

- The i.Sense technology can be implemented on any wear-resistant part with a minimum wall thickness of 2.5mm

- The test rig shows a test where the bearing displays different wear conditions and a service life prediction also becomes possible

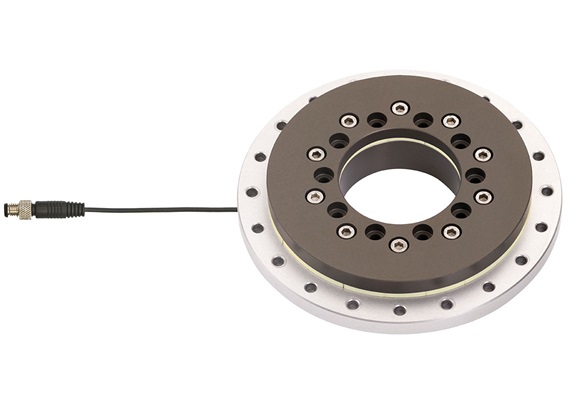

smart iglidur® PRT slewing ring bearings

- Easy to install with replaceable sliding elements

- High wear resistance

- For high loads, high rigidity

- Housing made of aluminium

Submit an enquiry now

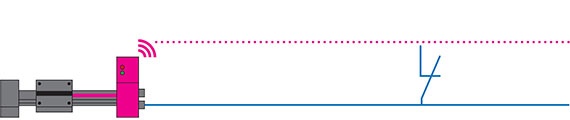

smart linear technology

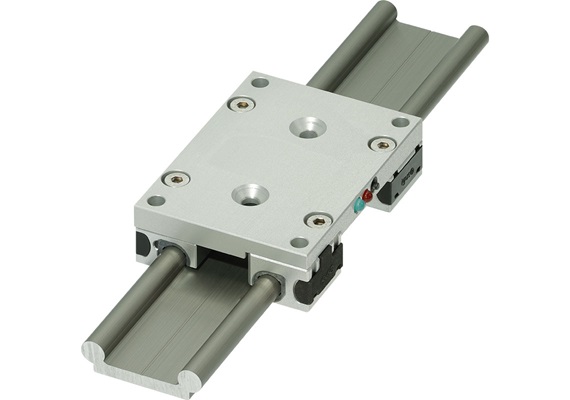

The smart drylin® W carriage

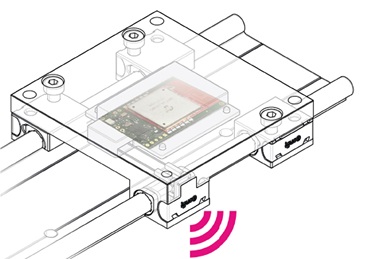

In addition to condition monitoring, with the help of the drylin W LED carriage it is also possible to fit a drylin W carriage for predictive maintenance.This not only indicates that the liners have become worn but also the best time to carry out a replacement. Therefore you always use the products with the maximum service life as you never replace them too early or too late.

Submit an enquiry for smart carriages

drylin® W linear carriage with LED

- Fast offline check

- Easy handling and visualisation by LED

- For drylin® W profile guides and linear modules

- Available in 2 installation sizes: 10 and 16

- Set of spare bearing liners available from stock

- Bearing replacement with practical mounting tool

to the drylin® W carriage

smart bearing technology sensors

DLT.W

Sensor for wear in drylin T linear systems

- Allows predictive maintenance (i.Cee)

- Integrated into the liner

- Reports wear of the liner in good time

- Predictable replacement of the sliding elements

DLW.W

Wear monitoring with the DLW.W sensor

- Allows predictive maintenance (i.Cee)

- A sensor measures the wear of the linear bearing in the drylin W linear guide

- If the limit is reached, it sends a signal to indicate that the bearing liner should be changed

PRT. W

Sensor for wear of iglidur® PRT slewing ring bearing

- Allows predictive maintenance (i.Cee)

- Sensor measures the abrasion of the sliding elements

- Predictable replacement of the sliding elements

isense plain bearing

Integrated wear measurement

- Allows predictive maintenance (i.Cee)

- Integrated sensor system measures wear