Sensors for smart chainflex® cables

smart plastics news 2023 ...

... experience now all smart plastics 2023 new products like the breakage monitoring for robot chains i.Sense TR.B or for the first time the new smart all-round service superwise right here:Industry 4.0: 2023 smart plastics News - overview

Cable quality monitoring CF.Q

- Avoid unplanned system downtime due to cable failures when using chainflex® cables outside the chainflex® guarantee conditions!

- Detect mechanical stress of chainflex® cables under extreme operating conditions at an early stage.

- Plan maintenance work cost-effectively in advance

Request CF.Q

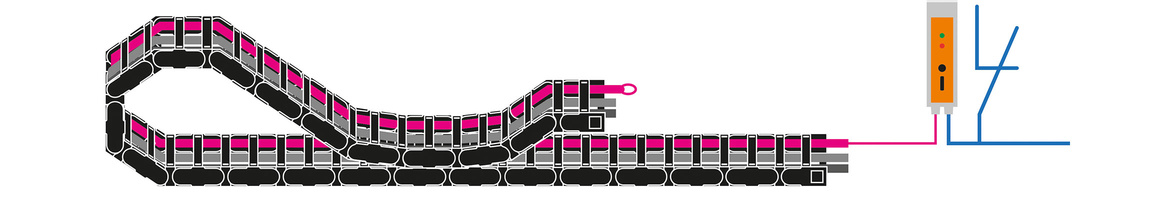

How CF.Q works

The isense CF.Q module is used for the early detection of the change in electrical specifications of chainflex® cables due to the mechanical loads during operation in an igus® e-chain system®. For this purpose, the electrical resistance of a dedicated conductor loop is measured during operation. Temperature-related resistance changes are compensated for by means of PT100 measurement at the installation location of the cable. Microprocessor-based, continuous data evaluation is carried out by own algorithms of igus®. These form arithmetic as well as sliding average values of the measured resistance values approx. 50 times per second and evaluate them in a temporal context.

If the system detects a permanent change in the electrical specifications, it recommends replacing the cable as soon as possible by switching a potential-free contact. If the cable is not replaced, the system switches off the system as a precaution in the event of a complete core rupture.

For later investigations, the system logs all measured values that led to the warning and shutdown.

Options to integrate CF.Q:

Option 1

as a sacrificial cable

In this option, space is still needed to route an additional cable in the e-chain® because the CF.Q is routed as a "sacrificial cable" in the e-chain®.All cores of the cable are "connected in series" and connected to the measuring input of the module.

Advantage: All cores are measured, which means that there is no need to select the most frequently used cores.

Disadvantage: Regardless of the production batch and the assembly method, even cables from the same production batch can achieve different service life durations.

Option 2

unused cores of a cable

In a monitored cable, two unused cores are defined as measuring cores and, if necessary, routed to the measuring connections of the CF.QA module by means of a shielded extension cable.This often requires a modification of the connector assembly, as the two cores must be led out of the connector on the distributor side at the cable entry.

Advantage: The cable actually used by the customer is monitored

Disadvantage: The original cable often has to be replaced by a variant with two additional cores, which usually increases the cable diameter, and the apparently "weakest" cores should be chosen.

An I4.0 success story from the field

- Application: Bread wrapping machine

- What was required: smart energy supply system

- Requirements: Preventive cable monitoring

- Product: CF.Q DIN rail module

- Field of application: Automation of any kind

- Success for the customer: The company GHD Georg Hartmann Maschinenbau was looking for a reliable energy supply system for one of its automatic packaging machines, including preventive monitoring to avoid machine failures

Go to the application report

Do you want to put together your own smart plastics package?

Then download the digital version of our smart plastics Domino now and put together your very own configuration.Afterwards, you can look forward to a playful treat from smart plastics.

Arrange a personal visit

Download smart plastics Domino (PDF)