After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

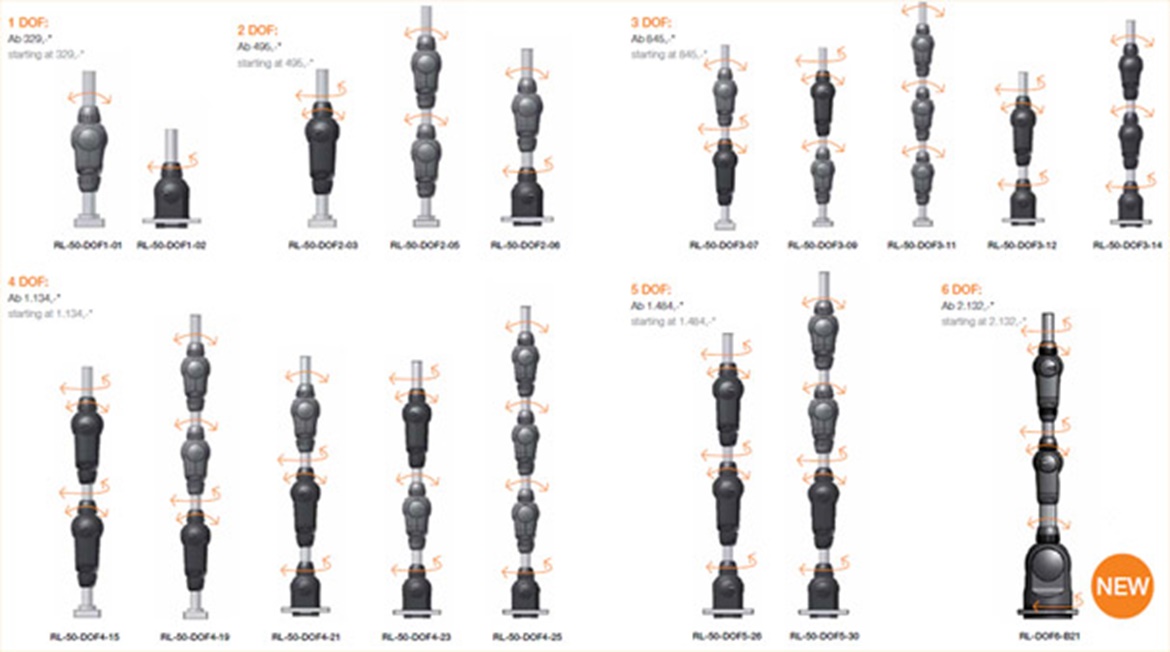

| Order number | Number Cables |

Pivot angle |

Angle of rotation |

Weight | Max. load | ||||

|---|---|---|---|---|---|---|---|---|---|

| Own drive |

Possible lead- through |

Standard (with stop dog) |

Option (*without stop dog) |

Standard (with stop dog) |

Option (*without stop dog) |

[gr] | Pivoting [Nm] |

Rotating [Nm] |

|

| 1. Pivot joint RL-50-PL1 |

2 | 4 | 180° (±90°) | 210° (±105°) |

- | - | 235 | 12 | - |

| 2. Rotating joint RL-50-TL1 |

2 | 8 | - | - | 340° (±170°) |

540° (±270°) |

245 | - | 5 |

3. 2-axis |

4 | 4 | 180° (±90°) |

210° (±105°) |

340° (±170°) |

540° (±270°) |

345 | 12 | 5 |

4. 2-axis |

4 | 4 | 180° (+130°/-50°) |

240° (+135°/-105°) |

340° (±170°) |

540° (±270°) |

345 | 12 | 5 |

| 5. 2-axis joint RL-50-003 |

4 | 4 | 180 ° (+180°/0°) |

235° (+180°/-55°) |

340° (±170°) |

540° (±270°) |

400 | 12 | 5 |

| 6. Basic joint RL-90-BL1 |

4 | 8 | 180° (±90°) |

190° (±95°) |

180° (±90°) |

- | 1250 | 20 | 10 |

Pneumatic hose (gripper)

2Quadruple Bowden cable

3Sensor cable - joint 2

44 wires move freely in the tub

5Single Bowden cable for rotation

68 wires move freely in the tub

Assembled joint made of plastic (PA 2200), incl. bearing locations (hard-anodised aluminium = Standard)

Dyneema wires

Aluminium rods (Standard = 100 mm included in each case, special lengths upon request)

Angle sensors as option (-WS), 3 m sensor wire, fitted and tested. Wire nipples as connecting material free of charge as agreed on with customer.

All joints preassembled in accordance with point 7)

All wires taken through with special Bowden cable segments in accordance with point 5)

Aluminium tubes between the joints, customised according to customer wishes

Mounting plate at the base of the arm

Sensor wires taken through (option -WS), 3 m sensor wire fitted and tested in each case. Wire nipples as connecting material free of charge as agreed on with customer.

igus® stepper motors, number corresponding to the number of axes of the arm

Planetary gearbox for each motor

"Drive wheel" for connection of the wires to the drive

"Tensioning tool" for easy re-tensioning of the drive wheels

Different versions of the housing in which the motors are fitted and on which the arm is mounted are available

Gripper (optionally available from igus®, other products also adaptable)

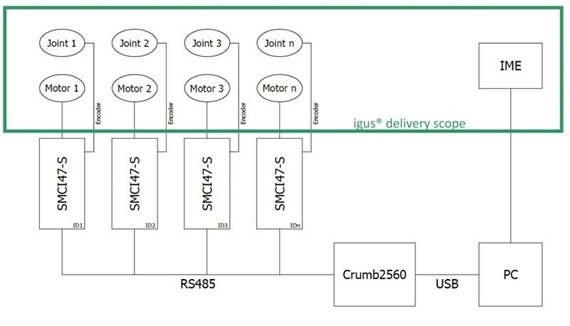

Control components

Motor cables (optionally available from igus®)

4,640 signals / 360° in the case of all rotational movements of joint size RL-50

(29 pole pairs x 160 signal / pole pair) ≈ 0.078°

4,960 signals / 360° in the case of all pivoting movements of joint size RL-50

(31 pole pairs x 160 signals / pole pair) ≈ 0.073°

9,920 signals / 360° in the case of all movements of joint size RL-90 ("Base")

(62 pole pairs x 160 signals / pole pair) ≈ 0.036

Hall sensor for rotating motion

2Encoder for rotating movement

3Encoder for pivoting movement

4Hall sensor for rotating motion

Stepper motor

2Planetary gearbox

3Tensionable drive wheel