80% less working time thanks to readychain

Pre-harnessed energy chains save space and weight in this machine tool series.

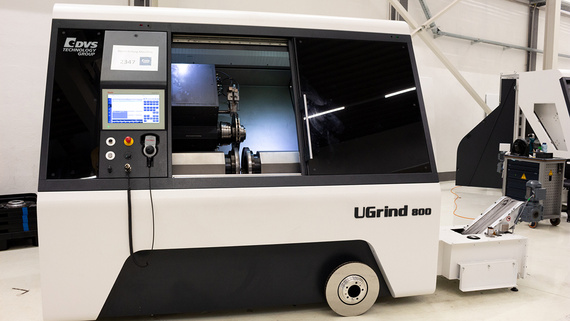

A universal machine for the workshop has always been the goal towards which DVS Universal Grinding GmbH has striven. The UGrind turns and grinds workpieces quickly, easily and cost-effectively. The company offers user-friendly machine tools for manufacturing everything from high-precision rotor shafts for electric drives to tools to hard-coated brake disks for sports cars. The focus is on the manufacture of small and medium-sized batches. For reliable energy supply, DVS Universal Grinding GmbH uses a ready-to-connect energy chain system that reduces working time by 80%.Profile

- What was needed: E4.1L energy chains, E4/light energy chain, both designed as pre-assembled readychain, chainflex cables

- Requirements: as the machine only takes up seven square metres of space, the chains also had to be incorporated in a tight installation space. It also had to be assembled quickly.

- Industry: Machine tool manufacturing

- Success for the customer: the pre-assembled chains save 80% of the client's working time during installation. The first machine with readychain has been in use 24 hours a day, six days a week for more than 18 months, operating without any problems.

Problem

Internal, external and face turning as well as internal, external and face grinding: this is what the DVS UGrind of DVS Universal Grinding GmbH can do. The company has specialised in hard-fine machining and developed a machine that can be used for all turning, measuring and grinding applications, on indoor and outdoor surfaces, in a single operation. The goal was to develop a simple, easy-to-operate machine that can produce even small workpiece quantities flexibly and cost-effectively.The UGrind 800 can be used to manufacture small to medium-sized batches, such as hollow shafts for electric drives or brake disks, with only one clamping. The machine can be operated with a touchscreen for controls, and in-depth programming knowledge is not necessary. Manufacture, including measurement and rework, is at the touch of a button, eliminating the necessity of active intervention on the part of the operator.

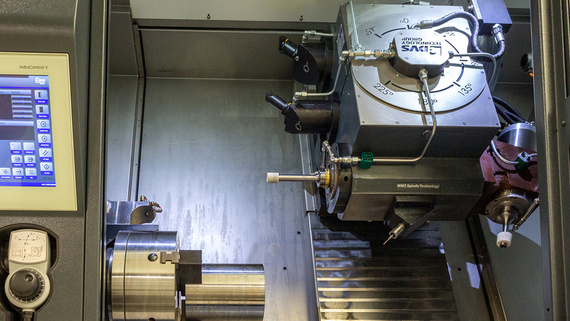

The heart of the UGrind is the multi-function turret, developed in-house, that can be equipped with up to five tools to support the application in question. The turret has an action radius of 270 degrees (±2″). With the proper tools, the UGrind can perform internal and external grinding, face grinding, cone grinding and various hard-turning processes. A measuring probe checks sizing and final dimensions, eliminating time-consuming rework. The multifunction turret can be configured depending on the user, and is easy to retrofit. In addition, the end user doesn't have to purchase several machines, which would take up valuable space.

Speaking of space, the system requires just seven square metres. To achieve this, all components must be ideally adapted to the installation space. An example is the energy supply system, which ensures that the multifunction turret is reliably supplied from cables, hoses and hydraulics. It also had to be assembled quickly.

Solution

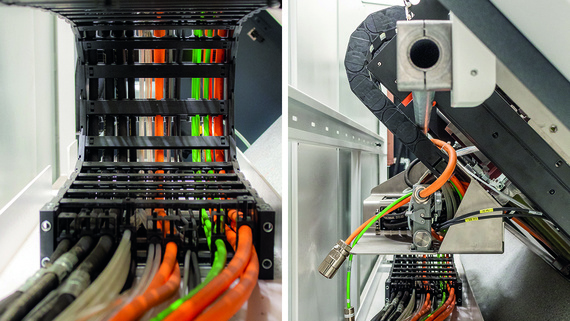

To supply energy and data, we offered the customer readychain - a complete energy chain system, which is ready to connect. While machine experts previously had to put together individual chain links themselves and thread cables laboriously, this work is a thing of the past with our harnessed system. Altogether, the manufacturer can save about 80% of working time. The energy supply system contains servo and encoder cables from the chainflex cable product range as well as hydraulics and coolant hoses. All components are already harnessed with the right plug-in connectors. The cables and hoses are specifically designed for use in the energy chain and are tested under real-world conditions in our in-house 3,800 square metre laboratory. Customers are offered a guarantee on the complete system.DVS Universal Grinding GmbH currently offers the machine series in two sizes. The UGrind 800 for workpieces with centre distances of not more than 1,200 millimetres and the UGrind 1500 for sizes of up to 1,800 millimetres. For the larger, functionally identical machine, the chain system merely had to be extended by three chain links. The readychain system installed in the machines today consists of three harnessed energy chains. In the Z-axis, two lightweight E4.1L energy chains (E4.38L series) supply the multifunction turret with the appropriate cables and hoses. They can be assembled quickly and are cost-effective. An E4/light energy chain (14240 series), which is also very lightweight and cost-effective, is used in the X-axis. Reduced side link thickness and a thinner crossbar gives the chain more room in its interior for cables. DVS Universal Grinding GmbH is also convinced of the quality of the energy chain systems. The first machine with the readychain has been in use for a customer in high-volume production 24 hours a day, six days a week for more than 18 months, without any problems.

Sabri Akdemir, CEO of DVS Universal Grinding GmbH