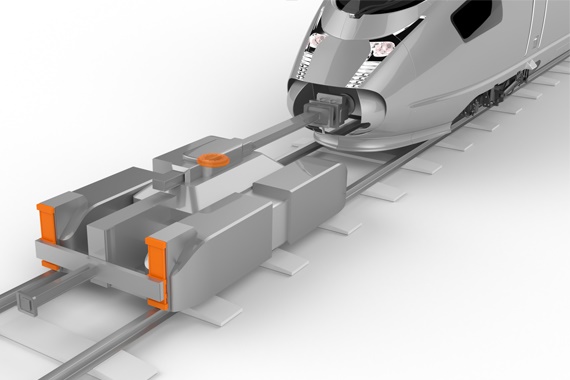

Bearings in a shunting locomotive made maintenance-free

Profile

- What was required? versatile components for bearings

- Manufacturing process: injection moulding

- Requirements: weather-resistant

- Industry: railway technology - special vehicles

- Success for the customer: maintenance-free slewing ring bearings and bar stocks

igus offers a variety of solutions for shunting locomotives. From the drylin drive technology and PRT slewing ring bearings to bar stock plates and tribotape. All these components contain high-performance polymers and are optimised for low wear and friction to guarantee a long service life. Therefore, igus components are used with high tensile forces and compressive strengths in shunting locomotives. Due to their incorporated solid lubrication, the igus components no longer require additional lubrication and are therefore maintenance-free. To adjust the coupling to the height of the wagon, drylin linear guides are used. In the joints of a screw coupling iglidur plain bearings can achieve a long service life without time-consuming maintenance and PRT slewing rings enable a smooth adjustment by hand or motor. With metallic parts such as coupling hooks that cause friction between each other, wear can be significantly reduced due to iglidur bar stock plates or even thinner tribotape.