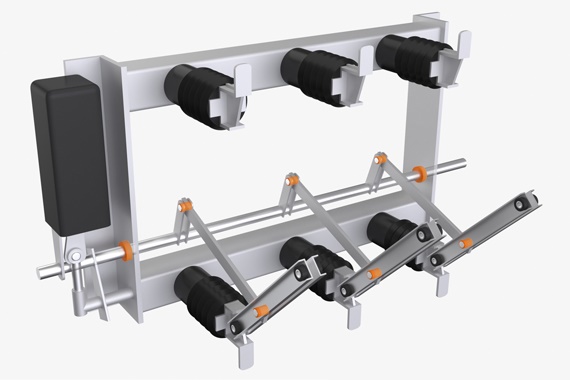

Low-maintenance parts for circuit breakers and earthing switches

Profile

- What was required? linear drive systems, lead screws and gears for circuit breakers and earthing switches

- Manufacturing process: injection moulding, 3D printing (selective laser sintering)

- Requirements: weather-resistant and robust components

- Material: iglidur J, iglidur I6

- Industry: railway technology – infrastructure

- Success for the customer: durable, low-maintenance components; dispensing with additional lubricants, individually manufactured gear

Along the railway line and in the train itself there are circuit breakers and earthing switches. Whether with medium or high voltage - a safe mechanical separation and connection must be guaranteed in the switches at all times. To make this possible even under demanding weather conditions, drylin drive systems and lead screw are used. With both, tribologically optimised high-performance polymers enable the movement without additional lubricants. The reason are incorporated solid lubricants, which contain both sliding elements of the drylin drive systems and the lead screw nut of the lead screw. Therefore, they are particularly low-maintenance in use.

Both in circuit breakers and in earthing switches there are additional bearings that can be optimised with iglidur plain bearings. They also already contain solid lubricants and hence reduce maintenance costs. Due to the versatile range of different iglidur materials, even electrically conductive plain bearings can be designed. There is also a suitable material for high loads and hard impacts.

Metallic gears can be replaced with 3D printed plastic gears. These are produced in a selective laser sintering procedure and are characterised by extremely high wear resistance and cost-effective manufacturing. Shape and size of the gear can be determined individually.