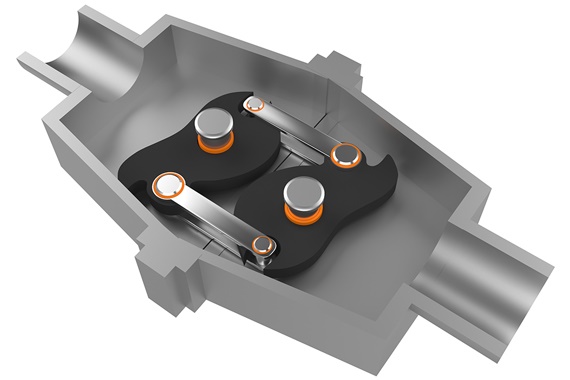

Coupling with maintenance-free bearings

Profile

- What was required? coiled plain bearings for train coupling

- Manufacturing process: injection moulding

- Requirements: weathering resistance, problem-free functionality with large amounts of dirt and snow

- Material: iglidur G, J and X

- Industry: railway technology - exterior

- Success for the customer: coupling works despite high loads and environmental impacts without maintenance

There are various application possibilities for iglidur plastic bearings in electric and pneumatic couplings. Due to their wear resistance, they contribute to a safe connection of the wagons. iglidur plain bearings are also used in shock absorbers and centre units. In Scharfenberg couplings, for example, they are used in the main pin so that the hooked plate can turn during coupling.

No matter whether a pivoting or linear movement is carried out, for both cases there are suitable iglidur plain bearings (coiled or injected) and thrust washers made of high-performance polymers. Both plain bearings and thrust washers are available in a variety of materials with different properties, so that plain bearings can be precisely tailored to the application conditions.

If bearings in couplings are equipped with iglidur plain bearings or thrust washers, this has further advantages in addition to wear resistance. They enable perfect functionality despite shocks and dirt and are corrosion-free. All iglidur materials contain incorporated solid lubricants, which make additional lubrication and maintenance redundant. By doing without additional lubrication, the plain bearings are very weather-resistant and perfectly suited for use in couplings. Functionality is always guaranteed, even with large amounts of dust or snow. In addition, they are characterised by high load capacity and a long service life, which can be precisely calculated with the free igus online tool.