Maintenance-free polymer bearings for robust sweeping vehicles

"Our sweeping machines do not surrender to any requirement," explains Dipl.-Ing. (BA) Helmut Schmeh, CEO of FAUN Viatec GmbH, a member of the German Kirchhoff Group, at the Grimma location. "They cover every working area and guarantee a convincing sweeping performance even under the most difficult conditions. " Whether as a road sweeper for the daily work in communities or in the heaviest use on construction sites, as an airfield sweeper for cleaning runways or as a manoeuvrable sweeper for smaller sites: they prove their robustness worldwide. They even show their efficiency in steel works, coal mining or oil spill removal. Niches such as rail cleaning or weed removal are also addressed with suitable attachments.

Problem

Extreme conditions such as moisture, salt, grit, coarse construction site dirt and oil spills make life difficult for the bearings used in the sweeping vehicle. Vibrations, shock loads and dynamics also have a strong influence on their service life. Bearings that can withstand these operating conditions are required.Solution

With plain bearings made of the materials iglidur Q, iglidur Z and iglidur W300, it was possible to cater to the individual application areas. Thanks to the maintenance-free operation and improved service life, costs have been significantly reduced. The media resistance of the plain bearings makes it easy to clean the affected areas. Previously, certain bearing points had to be lubricated to prevent failure, replacement or welding of components. With the plastic bearings from igus, wear only occurs in the bearing itself, which means that only the bearings need to be replaced.Helmut Schmeh, CEO of FAUN Viatec GmbH

No compromises on service life

The daily operating time of the vehicles is usually high. Customers demand efficient machines that must be efficient and durable in continuous use. No municipality and no service provider can afford long downtimes. But the fact is that the components installed are also tremendously stressed by the enormous amount of dirt accumulation. "If metallic bearings, for instance, are not lubricated regularly, they wear out very quickly," Dipl.-Ing. (FH) Gerhard Gräbel of the design department points out. "This limits not only daily working time, but comes with a cost. And lubricant also pollutes the environment." For these reasons, the company began looking for a low-maintenance solution in the field of bearing technology a number of years ago, which does not require any compromises in terms of service life.

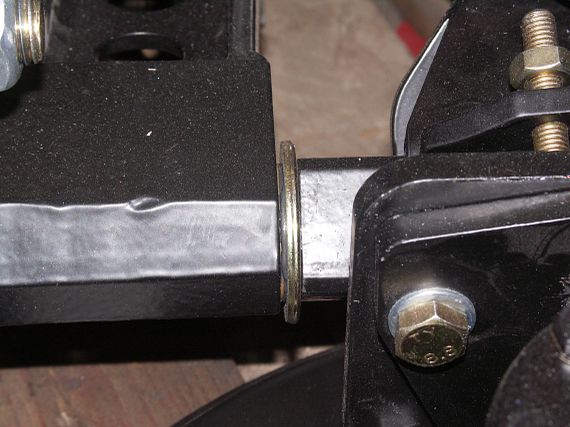

Neuralgic points: Rear lid and circular brush

To ensure the long-term durability of the sweeping vehicles, the company decided to use lubrication-free and therefore maintenance-free polymer plain bearings from igus. Plain bearings made of various iglidur® materials are used above all at the neuralgic points such as the circular brush, which for example is almost continuously exposed to high impact loads when sweeping the kerbs, and in the area of the rear lid, which is exposed to high forces when opening and closing. Added to this is the extreme accumulation of dirt at both points, which affects all areas.The particularly wear-resistant iglidur W300 and iglidur Q for maximum loads are used in the lifting joints of the circular brushes. In addition, iglidur Z, the material with the maximum surface pressure currently available, ensures outstanding wear resistancein the hinge and locking mechanism of the tail gate. "Dirt is unloaded via the tailgate. It gets really dirty and sometimes even wet. Since we have been using the polymer bearings, there is no longer any need for welding in case of repairs," Gerhard Gräbel points out. "If a defect should occur in a vehicle today, only the plastic bushings need to be replaced. This is simple by comparison. And we have the bushings in stock in our spare parts store."

"The test results clearly show that the brittle new material is likely to withstand everyday stresses and strains even better in the long term," says the designer confidently. "Thus the advantages for the machine operator are obvious. The robust sweeping machines are economical to operate in the long term while at the same time reducing maintenance and service costs," adds the CEO.

The cooperation between the two companies works very well. "We started our search for wear-free materials at a trade show a few years ago and subsequently made our first attempts with plastic plain bearings," Gerhard Gräbel recalls. "Our contact person on site is always available. We attach great importance to this. We also need samples or spare parts at short notice in order to maintain the value stability of the sweepers. And when it comes to new and further developments, we are now thinking in terms of plastics."

Polymer bearing for front brush

Further applications of the plastic bearings are already planned. For example, metal bearings are currently still being used in front brushes. They, too, must be lubricated regularly in order to remain functional in the long term. The first trials with lubrication-free plastic bearings are already underway.

Each year, around 250 sweeping vehicles are built at the site in a wide variety of volume production. The guidelines are clear. "Our customers demand efficient machines - with tight economic specifications," concludes the CEO. "We score points with German craftsmanship. With our robust and high-quality sweeping vehicles of all sizes, a wide range of cleaning tasks can be covered. In addition, we are sure that in the long run the lubrication-free plain bearings will prove themselves or prevail in other areas and ensure the required service life. “