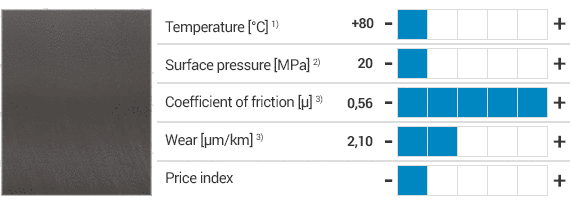

iglidur® M250 - Material data

The most important specifications at a glance

- Extremely resistant to edge pressure

- Very resistant to shocks and impacts

- Particularly resistant to dirt and dust

- Fogging behaviour according to DIN 75201-B

When do I use this material?

- When the bearings are exposed to severe

dirt - When high vibration dampening is necessary

- For low to medium speeds

- When mechanical reaming of the bore is necessary

- Resistant to edge pressure

- High impact resistance

- Thick walled according to DIN 1850

When do I use a different material?

- For applications in wet areas iglidur®

H, sleeve bearing, mm - When very high precision is required

iglidur® P, sleeve bearing, mm - For very smooth shafts

iglidur® J, sleeve bearing, mm - When a cost-effective bearing with maximum

wear resistance is required

iglidur® R, sleeve bearing, mm

Maximum surface speed

| m/s | Rotating | oscillating | Linear |

| Constant | 0,8 | 0,6 | 2,5 |

| Short-term | 2 | 1,4 | 5 |

Permitted surface speeds

As a standard, iglidur® M250 is manufactured as a thick-walled bearing. iglidur® M250 is best suited for low to medium surface speeds. The maximum permitted surface speeds in the dry operation are 0.8 m/s (rotating) and 2.5 m/s (linear) respectively. In practice these limit values are not always reached due to interactions.

Friction and wear

The coefficient of friction µ of a bearing is, among other things, influenced by surface speed and load (Fig. 04 and 05).| iglidur® M250 | Dry | Grease | Oil | Water |

| Coefficients of friction µ | 0,18 - 0,40 | 0,09 | 0,04 | 0,04 |

Table 04: Coefficients of friction for iglidur® M250 against steel (Ra = 1 μm, 50 HRC)

Shaft materials

The friction and wear are also dependent, to a large degree, on the counter partner. If you observe the coefficient of friction, then the ideal shaft surface finish for iglidur® M250 bearings is Ra = 0.6mm. Diagrams 06 and 07 display a summary of the results of tests with different shaft materials executed with plain bearings made of iglidur® M250. Up to loads of 2MPa the shaft material plays a relatively small role for rotational movements. Therefore, a suitable shaft material must be considered for higher loads. These are hardened shafts, such as Cf53 or hard-chromed. Diagram 07 shows that iglidur® M250 is much better suited for rotational motion than for pivoting movements. However, it must be mentioned that pivoting movements often cause high vibrations, which act on the bearing. This is where iglidur® M250 can show off its special dampening specifications. In our test, these vibrations are excluded for clarity so that the comparison between rotation and pivoting operation is accurate.Shaft materials

| Diameter

d1 [mm] | Shaft h9

[mm] | iglidur® M250

D11 [mm] | Housing H7

[mm] |

| Up to 3 | 0 - 0,025 | +0,020 +0,080 | 0 +0,010 |

| > 3 to 6 | 0 - 0,030 | +0,030 +0,105 | 0 +0,012 |

| > 6 to 10 | 0 - 0,036 | +0,040 +0,130 | 0 +0,015 |

| > 10 to 18 | 0 - 0,043 | +0,050 +0,160 | 0 +0,018 |

| > 18 to 30 | 0 - 0,052 | +0,065 +0,195 | 0 +0,021 |

| > 30 to 50 | 0 - 0,062 | +0,080 +0,240 | 0 +0,025 |

| > 50 to 80 | 0 - 0,074 | +0,100 +0,290 | 0 +0,030 |

Table 07: Important tolerances for iglidur® M250 bearings according to ISO 3547-1 after the press-in.

Installation tolerances

iglidur® M250 bearings require relatively large bearing clearances for optimum performances. These ensure that the bushings work reliably even with thermal expansion and water absorption. The disadvantages of the bearing clearance are again compensated by the vibration dampening properties. The bearings are designed for press-fit in a housing with h7 tolerance. After the installation in a housing with nominal diameter, the inner diameter of the bearing automatically adjusts to the D11 tolerance. The shaft should have at least an H9 tolerance.Additional properties

| Medium | Resistance |

| Alcohols | + to 0 |

| Hydrocarbons | + |

| Fats, oils, without additives | + |

| Fuels | + |

| Diluted acids | 0 to - |

| Strong acids | - |

| Diluted bases | + |

| Strong bases | 0 |

All specifications at room temperature [+20℃]

Table 05: Chemical resistance of iglidur® M250

Electrical properties

iglidur® M250 bearings are electrically insulating.

iglidur® M250 bearings are electrically insulating.

| Specific forward resistance | > 1013 Ωcm |

| Surface resistance | > 1011 Ω |