iglidur® L350 – material data

Material data table

| General specifications | Unit | iglidur® L350 | Testing method |

| Density | g/cm³ | 1,54 | |

| Colour | dark grey | ||

| Max. moisture absorption at 23 °C/50% r.h. | % weight | 0,4 | DIN 53495 |

| Max. total moisture absorption | % weight | 1,4 | |

| Coefficient of sliding friction, dynamic, against steel | µ | 0,07 – 0,18 | |

| pv value, max. (dry) | MPa x m/s | 3,00 | |

Mechanical properties | |||

| Flexural modulus | MPa | 15.882 | DIN 53457 |

| Flexural strength at +20°C | MPa | 210 | DIN 53452 |

| Compressive strength | MPa | 210 | |

| Recommended max. surface pressure (20°C) | MPa | 59 | |

| Shore-D hardness | 80 | DIN 53505 | |

Physical and thermal properties | |||

| Max. long-term application temperature | °C | +180 | |

| Max. short-term application temperature | °C | +210 | |

| Min. application temperature | °C | -100 | |

| Thermal conductivity | [W/m x K] | 0,61 | ASTM C 177 |

| Coefficient of thermal expansion (at 23 °C) | [K-1 x 10-5] | 7 | DIN 53752 |

Electrical properties | |||

| Specific volume resistance | Ωcm | > 105 | DIN IEC 93 |

| Surface resistance | Ω | > 105 | DIN 53482 |

Table 01: Materials table iglidur® L350

Download datasheet

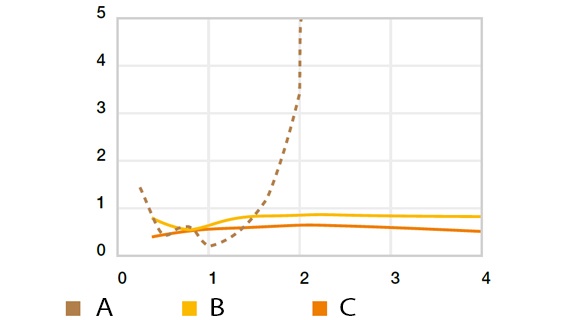

pv-values of iglidur® L350

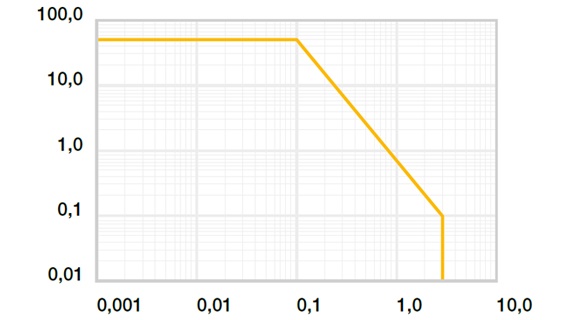

With iglidur L350, another lubrication and maintenance-free material is now available, which is designed for continuous high speeds. Due to the low thermal expansion and low moisture absorption, bearings can be manufactured with minimal potential to expand. iglidur® L350 is especially suitable for use in fans, blowers or electric motors – and the costs are also lower.Diagram 01: Permissible pv values for iglidur® L350 plain bearings with a wall thickness of 1 mm in dry operation against a steel shaft, at +20°C, mounted in a steel housing

X = Surface speed [m/s], Y = Load [MPa]

| Medium | Resistance |

| Alcohol | + |

| Hydrocarbons | + up to 0 |

| Greases, oils without additives | + |

| Fuels | + |

| Diluted acids | + |

| Strong acids | + |

| Diluted alkalines | + |

| Strong alkalines | + |

+ resistant 0 limited resistance - non-resistant

Electrical properties

| Specific volume resistance | > 105 Ωcm |

| Surface resistance | > 105 Ω |

Moisture absorption

The very low moisture absorption of 0.4 %weight in standard climatic conditions and 1.4 %weight at maximum water absorption also enables continuous operation in high humidity or in liquid media.Vacuum

In vacuum, the moisture content is released as vapour. Due to its low moisture absorption, use in a vacuum is possible.Radiation resistance

Plain bearings made from iglidur® L350 are resistant up to a radiation intensity of 2 x 10² Gy. Higher radiation affects the material and may result in a significant decrease in mechanical properties.UV resistance

The material properties of iglidur® L350 plain bearings do not change under UV rays or other weathering effects.Mechanical properties

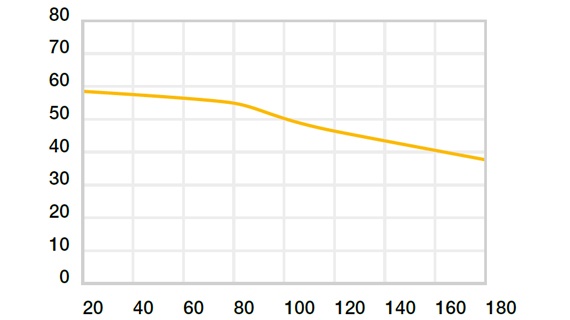

With increasing temperatures, the compressive strength of iglidur® L350 plain bearings decreases. The diagram 02 shows this inverse relationship. The recommended maximum surface pressure is a mechanical material parameter. No conclusions regarding the tribological properties can be drawn from this.

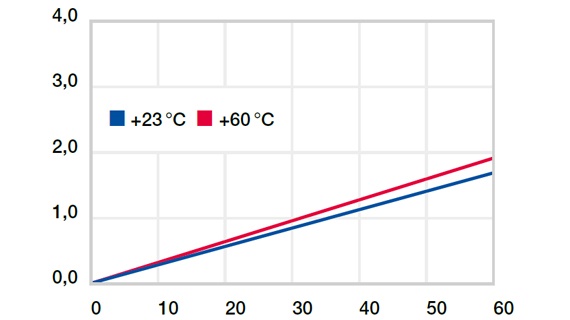

Deformation under load and temperature

Diagram 03 shows the elastic deformation of iglidur® L350 under different loads. At the recommended maximum surface pressure of 59 MPa the deformation is less than 2,5 % at room temperature. A plastic deformation can be negligible up to this value. It is however also dependent on the duty cycle of the load.

Maximum running speed

| m/s | Rotating | Oscillating | linear |

| Continuous | 3,0 | 1,5 | 4,0 |

| Short-term | 4,0 | 3,0 | 6,0 |

Permissible surface speeds

iglidur® L350 has been developed especially for high surface speedswith low loads. Due to the high

temperature resistance of iglidur® L350, the physical

limit of the bearing has been,

increased significantly. In addition, the extremely

low wear allows long sliding distances to be attained quickly

in the case of high peripheral speeds. The maximum

speeds are shown in adjacent table.

| iglidur® L350 | Application temperature |

| Minimum | - 100 °C |

| Max. long-term | + 180 °C |

| Maximum, short-term | + 210 °C |

| In addition secure axially from | + 140 °C |

Temperatures

The iglidur® L350 plain bearings can be used in temperatures up to +210°C for the short-term. Note that a mechanical securing of the bearing is recommended from temperatures of +140°C. Higher temperatures can also cause the bearing to lose its press-fit seating and move in the hole.

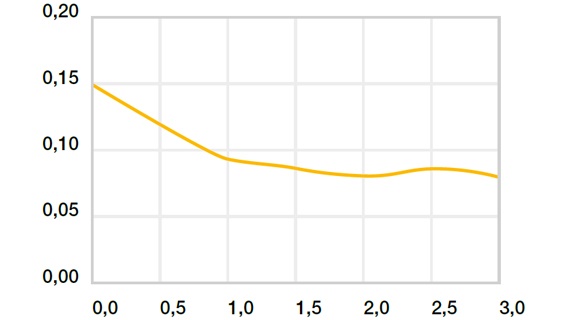

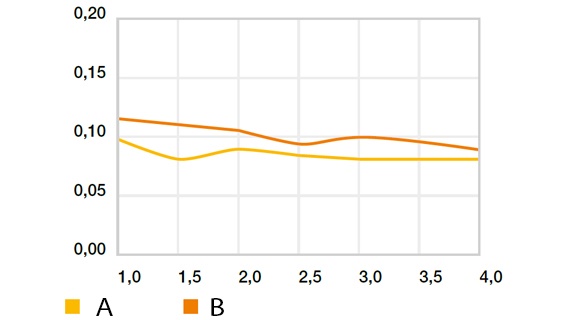

Friction and wear

The very low coefficient of friction remains, even at high speeds. Diagram 04 shows this relationship on a steel shaft at 0.75 MPa surface pressure.| iglidur® A300 | Dry | Greases | Oil | Water |

| C. o. f. µ | 0,07 - 0,18 | 0,06 | 0,04 | 0,03 |

Table 06: Coefficients of friction for iglidur® A350 against steel (Ra = 1 µm, 50 HRC)

Shaft materials

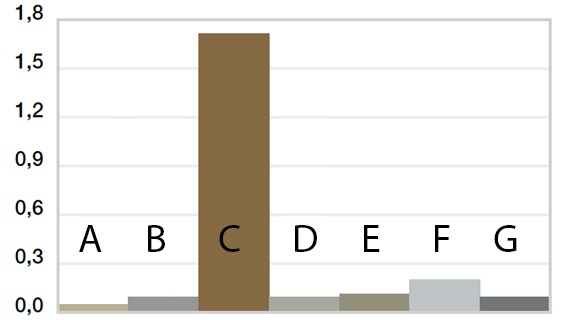

Diagram 05 compares the wear of a sintered bearing with that of bearings made of the materials iglidur® L500 and L350. At a surface speed of 1.5 m/s or more, the wear of the sintered bearing increases exponentially whereas the wear of the iglidur® plain bearings almost remains the same up to a speed of more than 3 m/s.A = Aluminium, hard-anodised

B = Free cutting steel

C = Cf53

D = Cf53, hard-chromed

E = St37

F = V2A

G = X90

Shaft materials

| Diameter d1 [mm] | Shaft h9 [mm] | iglidur® A350 F10 [mm] | Housing H7 [mm] |

| to 3 | +0,000 +0,010 | +0,006 +0,046 | –0,025 +0,000 |

| > 3 to 6 | +0,000 +0,012 | +0,010 +0,058 | –0,030 +0,000 |

| > 6 to 10 | +0,000 +0,015 | +0,013 +0,071 | –0,036 +0,000 |

| > 10 to 18 | +0,000 +0,018 | +0,016 +0,086 | –0,043 +0,000 |

| > 18 to 30 | +0,000 +0,021 | +0,020 +0,104 | –0,052 +0,000 |

| > 30 to 50 | +0,000 +0,025 | +0,025 +0,125 | –0,062 +0,000 |

| > 50 to 80 | +0,000 +0,030 | +0,030 +0,150 | –0,074 +0,000 |

| > 80 to 120 | +0,000 +0,035 | +0,036 +0,176 | –0,087 +0,000 |

| > 120 to 180 | +0,000 +0,040 | +0,043 +0,203 | +0,000 +0,100 |