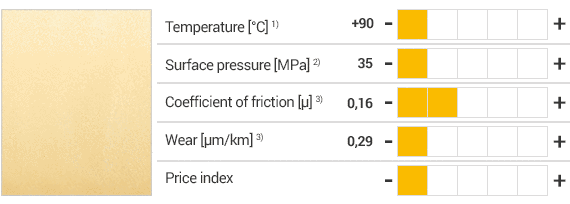

iglidur® J - Material data

The most important specifications at a glance

- Excellent wear resistance at room temperature

- Good wear resistance at medium temperatures

- Excellent friction coefficients

- Low moisture absorption

- High media resistance

- Resistant to edge pressure

- Resistant to shocks and impacts

- Resistant to dirt and dust

- Mould resistant according to DIN EN ISO 846

When do I use this material?

- For high speeds

- When highest wear resistance at low to medium pressures is required

- Low wear against different shafts

- When a low coefficient of friction in dry operation is requested

- For vibration dampening

- When good chemical resistance is required

- For best performance with soft shaft materials

- Low moisture absorption

When do I use a different material?

- When high pressure loads occur

iglidur® G, sleeve bearing, mm

iglidur® W360, sleeve bearing, mm - When temperatures higher than +120°C occur in the short-term

iglidur® G, sleeve bearing, mm

iglidur® Z, sleeve bearing, mm - When looking for a cost-effective bearing for occasional movements

iglidur® G, sleeve bearing, mm

Maximum surface speed

| m/s | Rotary | oscillating | Linear |

| Constant | 1,5 | 1,1 | 8 |

| Short-term | 3 | 2,1 | 10 |

Table 02: Maximum surface speeds

Permitted surface speeds

The low coefficients of friction and the very low stick-slip tendency of iglidur® J bearings are particularly important at very low speeds. However, iglidur® J can also be used for high speeds of over 1 m/s. In both cases the static friction is very low and stick slip does not occur. The maximum values shown in table 02 can only be achieved at low pressures. At the given speeds, friction can cause a temperature increase to maximum permissible levels. In practice, though, this temperature level is rarely reached due to varying application conditions.| iglidur® J | Dry | Grease | Oil | Water |

| Coefficients of friction µ | 0,06 - 0,18 | 0,09 | 0,04 | 0,04 |

Table 04: Coefficients of friction for iglidur® J against steel (Ra = 1 μm, 50 HRC)

Friction and wear

Just like the wear resistance, the coefficient of friction µ also alters with the load (Fig. 04 and 05).

Shaft materials

The friction and wear are also dependent, to a large degree, on the counter partner. With increasing shaft surface finish, the coefficient of friction also increases. The best case is a ground surface with an average surface finish Ra = 0.1–0.3 μm. Diagrams 06 and 07 display a summary of the results of tests with different shaft materials executed with plain bearings made of iglidur® J. When compared to most other iglidur® materials, iglidur® J plain bearings have very low wear results at low loads compared with all shaft materials tested. Also, for increasing loads up to 5 MPa, the wear resistance of iglidur® J plain bearings is excellent. If the shaft material you intend to use is not included in the test results presented here, please contact us.Shaft materials

| Diameter d1 [mm] |

Shaft h9 [mm] |

iglidur® J E10 [mm] |

Housing H7 [mm] |

| Up to 3 | 0 - 0,025 | +0,014 +0,054 | 0 +0,010 |

| > 3 bis 6 | 0 - 0,030 | +0,020 +0,068 | 0 +0,012 |

| > 6 bis 10 | 0 - 0,036 | +0,025 +0,083 | 0 +0,015 |

| > 10 bis 18 | 0 - 0,043 | +0,032 +0,102 | 0 +0,018 |

| > 18 bis 30 | 0 - 0,052 | +0,040 +0,124 | 0 +0,021 |

| > 30 bis 50 | 0 - 0,062 | +0,050 +0,150 | 0 +0,025 |

| > 50 bis 80 | 0 - 0,074 | +0,060 +0,180 | 0 +0,030 |

| > 80 bis 120 | 0 - 0,087 | +0,072 +0,212 | 0 +0,035 |

| > 120 bis 180 | 0 - 0,100 | +0,085 +0,245 | 0 +0,040 |

Table 07: Important tolerances for iglidur® J bearings according to ISO 3547-1 after the press-fit.

Installation tolerances

iglidur® J bearings are standard bearings for shafts with h-tolerance (recommended minimum h9). The bearings are designed for press-fit in a housing with h7 tolerance. After the installation in a housing with nominal diameter, the inner diameter of the bearing automatically adjusts to the E10 tolerance. In certain dimensions the tolerance in dependence on the wall thickness deviates from this (See delivery program )| Medium | Resistance |

| Alcohols | + |

| Hydrocarbons | + |

| Greases, oils without additives | + |

| Fuels | + |

| Diluted acids | 0 to - |

| Strong acids | - |

| Diluted bases | + |

| Strong bases | + to 0 |

All specifications at room temperature[+20 °C]

Table 05: Chemical resistance of iglidur®

Electrical properties iglidur® J bearings are electrically insulating.

| Specific forward resistance | > 1013 Ωcm |

| Surface resistance | > 1012 Ω |

Further properties

chemical resistanceiglidur® J bearings are resistant to diluted alkalis and very weak acids as well as to fuels and all kinds of lubricants. The low humidity absorption allows them to be used in wet or humid environment. The bearings made of iglidur® J are resistant to common cleaning agents used in the food industry.

Radioactive rays The iglidur® J bearings are radiation resistant up to a radiation intensity of 3 • 102 Gy.

UV-resistantiglidur® J bearings change color under the influence of UV rays. However, the material properties do not change.

VacuumIn vacuum, iglidur® J plain bearings degases. For this reason only dry bearings are suitable for vacuum.