Minimal wear, maximum hygiene: Plain and linear bearings in filling lines

Self-lubricating bearing technology in beverage filling plants from Küppersbusch GmbH

Küppersbusch GmbH in Velbert develops and manufactures customer-specific filling plants and has been using plain bearings from the igus modular construction system for more than twenty years. A closer look at a manufactured plant shows a wide variety of possible applications for bearing systems made of high-performance polymers in beverage technology.Profile

- What was needed: drylin trapezoidal thread, igubal clip bearing, drylin R fixed flange bearing, tribo-tape liner, drylin T rail guide, iglidur flange bearing

- Requirements: All rotary and linear bearings must be easy to clean and have a long service life. For hygiene reasons, they must not require any external lubricants, and the material of the parts in contact with the product must be FDA-compliant.

- Industry: Packaging, beverages sector

- Success for the customer: The bearing portfolio offers components for all requirements: The bearings made of high-performance polymers are lubrication-free, virtually wear-free and FDA-compliant. The users of Küppersbusch systems can therefore do with a minimum of service.

Problem

It is frequently small companies in the beverages sector that set important trends and, at least in the beginning, produce smaller amounts. When they want to invest in a partially or fully automated filling system, they often turn to Küppersbusch GmbH in Velbert. A typical feature of Küppersbusch's procedure is that there are no prefabricated solutions or type series. Since most customers want flexible systems in smaller quantities, the solution often consists of semi-automatic, linear filling, labelling and sealing machines.For all plant components in these systems, it is important that both the rotary and linear bearings can be cleaned easily and achieve a long service life. They must not require external lubricants for hygiene reasons, and the materials of parts that come into contact with the product must be FDA-compliant.

The example of a bottling plant for spirits, which is currently undergoing its final test runs in Velbert before delivery, is a good illustration of how many and which different plain bearings from the igus modular system are used here.

Here, the designers benefit from the constantly growing variety of the iglidur material selection range. Today, instead of the material iglidur A180, the new FDA versions iglidur A181 (blue) and the likewise FDA-compliant high-temperature bearing iglidur A500 are mostly used.

Solution

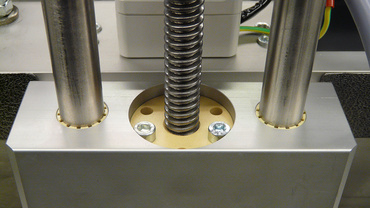

Height and format adjustments:For various height adjustments, drylin trapezoidal threads in combination with flange nuts made of high-performance polymers are used (see picture 1 below). The format adjustments are made via drylin R flange bearings (picture 2).

Electric motor bracket:

The igubal clip bearings are installed on the bracket of an electric motor to ensure easy installation (picture 3).

Vertical linear axis:

On another (vertical) linear axis, Küppersbusch has been using a combination of drylin R fixed flange bearings with aluminium adapters in which anodised aluminium shafts move for many years (picture 4). It does not need any lubrication and is almost wear-free.

Rotary table outlet and bottle feed:

The outlet of the rotary table, when feeding the bottles, was originally made of stainless steel. In order to dampen the noise of bottles hitting metal, tribo-tape made of iglidur B160 is used at present (picture 5). The liner is resistant to cleaning agents and is characterised by a very good coefficient of sliding / friction compared to glass.

Filling and dosing stations:

At the valves and pumps of the filling and dosing stations, the bottles are drylin T rail guides and connected to the filler. At the centring bridges of the filling tubes, the company installs iglidur flange bearings (picture 6), which are not only FDA-compliant and chemically resistant, but also have an extremely long service life.

Klaus Voigt, project engineer at Küppersbusch on the iglidur flange bearings at the filling and dosing stations