30 years of iglidur® - 30 years of research

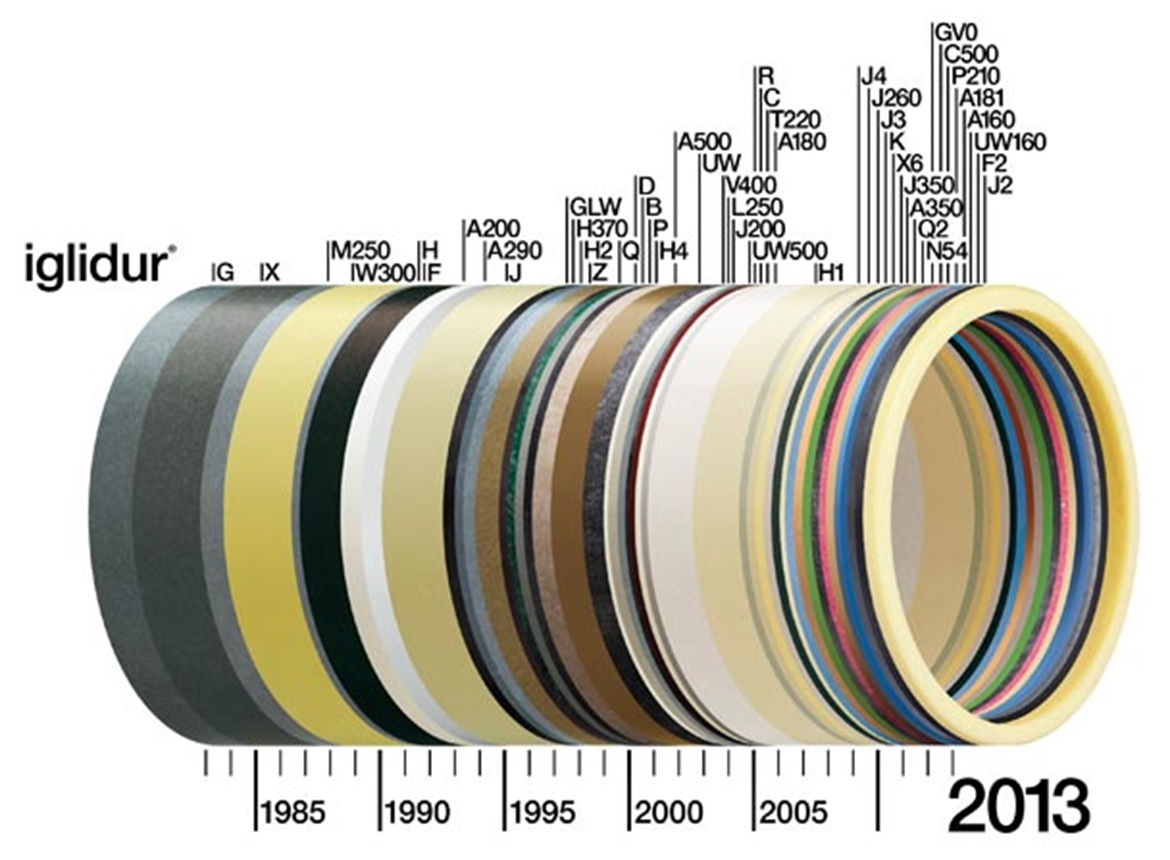

From the first tentative attempts to get started in 1983 with few parts, it has evolved over time through intensive research and learning into a mature product range with numerous options for dry operation and cost reduction.

igus® presented the first iglidur® bearings at the "K" Trade Fair in Dusseldorf 30 years ago.

igus® presented the first iglidur® bearings at the "K" Trade Fair in Dusseldorf 30 years ago.

The iglidur® product range from igus® has been available now for exactly 30 years. The name stands for plain bearings made of high performance plastics which have been optimised in terms of wear and friction coefficients over the decades by our in-house research. All plastic plain bearings from igus® contain millions of tiny little solid lubricants that make an external lubrication unnecessary. This makes them ideal for unusual applications such as underwater, in a dirty environment or in the food industry.

[Uncover linktext="Read more ..."] There are now around 100 different formulas, of which 40 are used in the series. Thereby, a special bearing that precisely matches the special requirements is available for virtually every application. For, similar things apply to plain bearings and athletics: There are the decathletes, who are all-rounders in a certain way and have balanced skills in all areas. And there are specialists such as sprinters, throwers and jumpers who are superior in their disciplines, but cannot give top performances in other disciplines at times. For the next 30 years we want to train our athletes even further and optimise - so that they are always guaranteed to give the maximum performance and service life.

With the "iglidur® world tour", we will demonstrate to you what plastic plain bearings can perform today. On the occasion of the anniversary, we are sending a small car equipped with our iglidur® products around the world. It will stop at our offices, partners, trade fairs, manus® participants and customers. Experience with us a year full of exciting stories and interesting impressions, before the car returns to Cologne in the autumn of 2014.

Yours, Gerhard Baus Authorised representative for plain bearings, igus® GmbH

Yours, Gerhard Baus Authorised representative for plain bearings, igus® GmbH

More on "iglidur® on tour"

Millions of bearings in use

Polymer bearings applications overview

Polymere bearings application examples overviewPolymer bearings applications overview

manus® competition 2023

11th competition for innovative plastic plain bearing applicationsmanus® competition 2023

iglidur® product overview

iglidur: Large range of Bushing & Accessories from igus®iglidur® product overview

iglidur® plain bearing expert

Using the iglidur® plain bearings expert you can get, after only a few inputs about your application, an overview of suitable iglidur® materialsiglidur® plain bearing expert

iglidur® on tour 2013-2014

As part of the 30th iglidur® anniversary, the tribological polymer specialist from Cologne is sending a small car on a long trip

With the "iglidur® on tour", igus® celebrates the anniversary at this year's K: a small car with a plastic body is equipped with iglidur® components and sent on a trip around the world. With this action, igus® demonstrates not only the diverse application of its polymer plain bearings worldwide, but also the performance capability of iglidur®.Go to "iglidur® on tour" blog

From 1983 till today

"I'm always surprised when we implement something

with lubricant-free plastics today, which we

could hardly have dreamt of a few years

ago. “

Frank Blase, Managing Director of the igus® GmbH in Cologne

Frank Blase, Managing Director of the igus® GmbH in Cologne

"Our customers are our foremost inspiration. With

new areas of application, they always provide us with

new challenges. There is the 'manus®'

developer's prize for your most courageous solutions with

plastic plain bearings. “

Gerhard Baus, Head of the Plastic Plain Bearings division

Gerhard Baus, Head of the Plastic Plain Bearings division

"The smallest change in the mixture can fundamentally

revolutionise a polymer material.

Therefore we run more than 3,000 tests annually with

about 150 experimental materials. Only the best

make it into the catalogue. “

Dr. Ralf Selzer, Head of Development of Plain Bearings

Dr. Ralf Selzer, Head of Development of Plain Bearings