Recycling adapter for liners

Linear bearings made from eco-materials

Linear housings made of 100% recycled igus® polymer P4 and liners made of iglidur® J4 with high recycling material content. The split linear housings also enable fast bearing replacement directly on the round shaft.Questions about the product

More information on drylin R shaft guides

Tech up

- Split linear housing made of iglidur® ECO P, 100% recycled material, 0% CO2 footprint

- Liner made of iglidur® J4 with high recycled material content and a CO2 footprint that is 60% lower than that of standard liners made of iglidur® J.

Cost down

- Lightweight due to 100% plastic

- Splittable bearing halves for bearing replacement directly on

the shaft - For all round shafts: Steel/stainless steel hardened

or drawn, hard anodised aluminium or

carbon

Proof

- Weight comparison: 27g TJ4UMP-01-20-RECP recycled adapter, 49g TJUM-01-20 aluminium adapter, weight savings of about 50%

Sustainability

- 100% elimination of lubricants

- Reuse of igus® plastics

- Reusable adapter

- igus® has been an investor in Mura Technology from the very beginning, and is advancing chemical recycling. From plastic waste to crude oil in 20 minutes:

igus.eu/hydroprs

Download current catalogue

Go to the PDF downloads

Further drylin® products

Go to the other products

Application examples of our drylin® products

igus® helps prospective carpenters with their project

As part of a course in machinery at the Cologne Chamber of Crafts, prospective carpenters combined Scandinavian looks with industrial design. The results of this project are a pull-out bedside table and a coffee table with rotating drawer and pull-out opening. The pieces of furniture are not only beautiful to look at, but have a certain quality.

To the application example

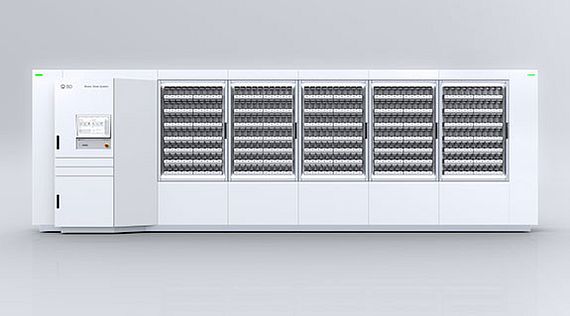

igus® in the storage technology of a blister centre

igus® stoarge technology in an automated blister centre. Automated medicine handling for pharmacies: with over 7,500 systems installed worldwide, Rowa Systems from Becton Dickinson are market leaders.

To the application example

igus® components in KHS labelling machines

Numerous rotary and linear bearings from the igus® product range are not the only ones installed in KHS GmbH's labelling machines. igus® also supplies complete, ready-to-install modules here, e.g. adjustment systems and support rollers.

To the application example

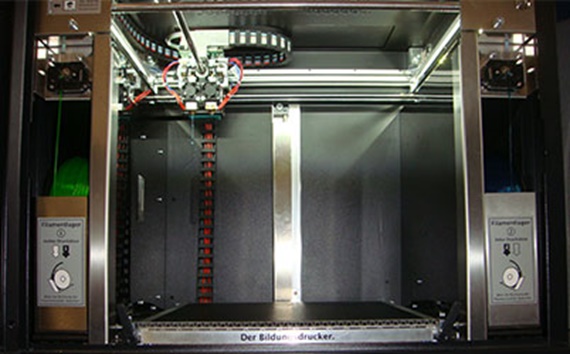

Linear guide components for 3D printers

Tech-savvy start-ups are more daring than others in turning emerging technologies into new, marketable products. This is also the case with fabmaker GmbH, Braunschweig, which has developed a 3D printer for the school and training sector.

To the application example