Long-lasting gear shift bearing reduces noise in the driver's cab

Better shifting comfort, less vibrations: wear-resistant iglidur G fixed flange bearings in gear shift

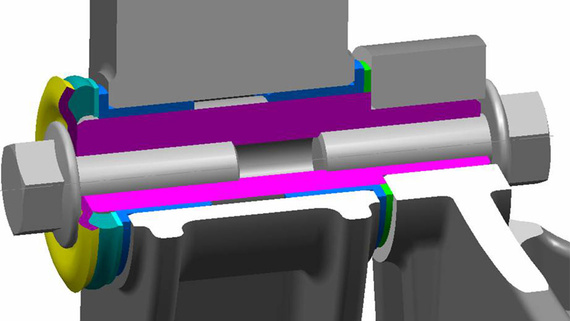

This application serves on the one hand to improve the shifting comfort and on the other hand to reduce the vibration-induced noise in the driver's cab. By enlarging the bearing position, two iglidur G fixed flange bearings could be installed with a step-free pin. The rigidity of the bearing point was thus increased and the vibration impulses of the driver's cab were reduced. With an additional iglidur G thrust washer, friction and wear could also be reduced.Profile

- What was needed: iglidur G fixed flange bearings; iglidur G thrust washers

- Requirements: Flexurally stiff and durable bearing, which reduces the vibration-induced noise in the driver's cab and operates reliably and maintenance-free in the gear shift system

- Industry: Automotive industry

- Success for the customer: Vibrations and noise in the cabin were reduced by the bend-resistant iglidur fixed flange bearings; reduced friction and the wear resistance of the bearings increase the service life of the solution and make it maintenance-free; at the same time, manufacturing costs were reduced

Problem

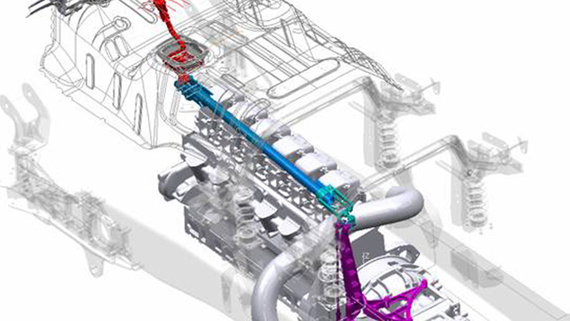

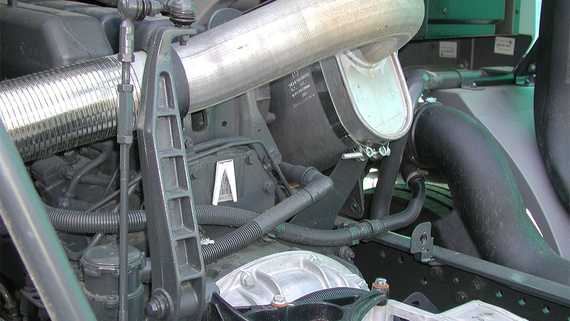

This application involves the swing arm bearing of a deflected cab-mounted gear shift in the AXOR-C

(SOP 2001) utility vehicle from Daimler AG.

The car manufacturer had two central goals with regard to the optimisation of the swing arm bearing: On the one hand, the suspension had to be flexurally stiff and durable in order to improve driving comfort, and on the other hand, it had to reduce the noise in the driver's cabin caused by vibrations.

In order to work reliably in the gear shift in the long term, they were also looking for a long-term solution that would not require any maintenance. Here, the material selection of the bearing was paramount.

Solution

By enlarging the bearing position, two iglidur G fixed flange bearing could be installed with a step-free pin. The rigidity of the bearing point was thus increased and the vibration impulses of the driver's cab were reduced. Thus, noise in the driver's cab caused by vibrations could also be reduced. With an additional iglidur G thrust washer, friction and wear could also be reduced. (Friction partner: flange bushing / thrust washer). By optimising the coefficients of friction, the component also has a longer service life, while the need for maintenance is eliminated. And if problems do arise with the gear shift, the bearings can be easily removed and quickly replaced. The simplified geometry and the elimination of case hardening of the pin reduced the manufacturing costs at the same time.