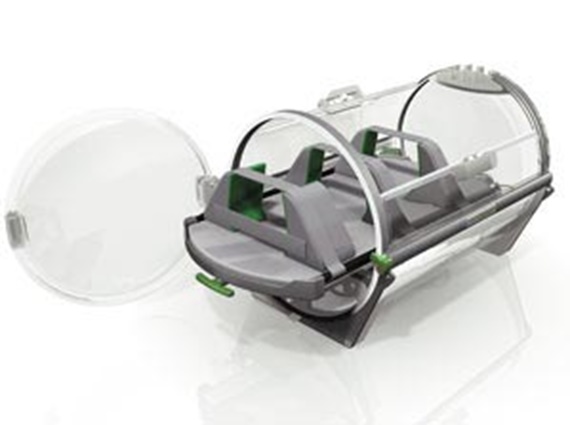

Transport incubators to move critically sick newborn babies

by ambulance or aircraft between hospitals

Transport incubators have changed little since the 1950s and are currently based on an inappropriate fixed ward incubator design. This means they are heavy, difficult to use, and offer little protection to the baby from the extreme challenges faced during transportation, such as noise, vibration and vehicle accidents. The Neo-Capsul opens to allow the bed to slide out as far as possible from the enclosure to enable the baby to be reintubated: a frequent procedure absolutely critical to the survival chances of the baby. It was important that the bed action was smooth, reliable, did not require lubrication and crucially met infection control protocols. The linear transfer device also needed to operate under tight spatial constraints to ensure maximum space was left for neonate care. igus® drylin® W polymer linear bearings dramatically increased bed stroke and stability over polymer competitors’ products and offer a significant USP to the market. The system is also non-lubricated, ® cost effective, exceeds infection control protocol, fits with the clean aesthetic of the Neo-Capsul and is a silent, low maintenance solution. The compact nature of the rail design also ensures that maximum space is provided for the baby. "igus® linear rails were the key component which helped us to solve a critically important design challenge which will help save the lives of very sick babies."

Rory Wilkinson

Director and Design Engineer

Leightweight Medical

Director and Design Engineer

Leightweight Medical