Centrifugal clutch with long service life due to polymer bearings

Wear-resistant iglidur plain bearings increase the service life of centrifugal clutches

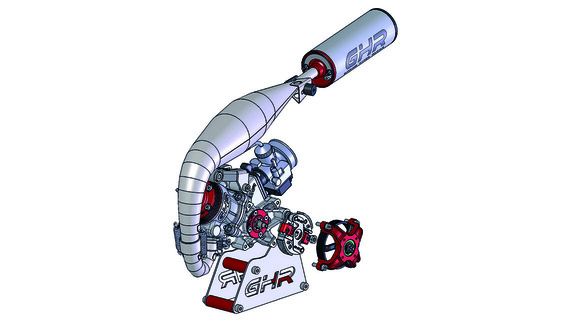

Giprime Hyper Racing is a company that builds centrifugal clutches used in two-stroke racing machines. Clutches of this kind are normally mounted without plain bearings, leading to fast wear. Using highly abrasion-resistant plastic plain bearings greatly increases the service life and eliminates the necessity of replacing the entire coupling.Profile

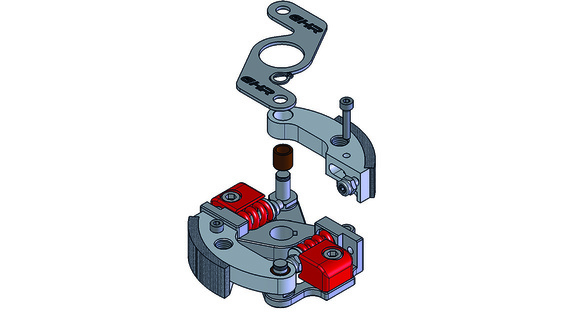

- What was needed: Cylindrical iglidur H4 plastic plain bearings

- Requirements: High wear resistance under extreme conditions

- Industry: Automotive, racing

- Success for the customer: The customer no longer has to replace the entire coupling, just the bearing alone; increasing the service life. Replacement also requires less time and money.

Problem

This Giprime Hyper Racing centrifugal clutch is used in two-stroke racing machines. The function of a centrifugal clutch is to establish the frictional connection from the engine to the drive. As speed increases, the clutch discs are pressed outwards onto the clutch case. This creates a constant pivoting movement for which bearing installation is suitable. Clutches of this kind are normally mounted without bearings, leading to fast component wear. As a result, they often have to be completely replaced after a short time.So the manufacturer's problem was high wear on the pin and coupling fasteners. Because they are used in racing machines, stress is much higher than in normal scooters.

Solution

The Giprime Hyper Racing clutch therefore now uses iglidur Z slide bushings, which can withstand even the heavy loads encountered in racing. They feature particularly long service life under extreme conditions, wear resistance, and impact resistance at high loads and temperatures. In the case of Giprime Hyper Racing, this has greatly reduced the friction between the pin and the housing and increased the clutch's service life.And it is no longer necessary to replace the entire centrifugal clutch, but simply the plastic plain bearing, which takes just a few minutes. This saves the customer time and money.

Plastic plain bearings also require much less time to adjust than metal bearings do. This is especially important in racing.