Precision at high speed: Linear bearings in thermoforming machine

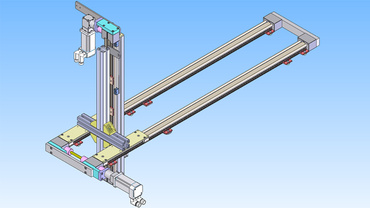

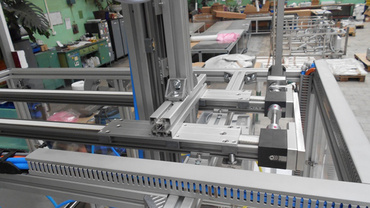

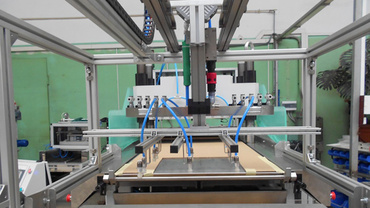

drylin ZLW toothed belt axes enable fast and precise positioning of the arm stacker.

This thermoforming machine adapts perfectly to new packaging sizes. The parts to be packaged are automatically positioned and then packaged in different sizes. drylin linear bearings ensure precise positioning at high speed. Unlike conventional bearings, they do not need to be lubricated and are corrosion-resistant. This increases efficiency and reduces maintenance times.Profile

- What was needed: drylin ZLW toothed belt axis

- Requirements: The solution had to be particularly flexible, able to receive packages in a variety of sizes and shapes automatically and at the same time ensure high process efficiency. The primary objective was also to be completely lubrication-free.

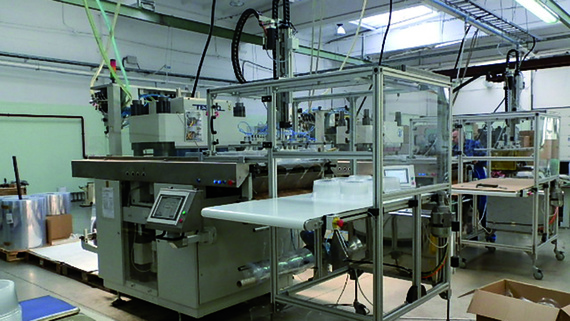

- Industry sector: Packaging technology, thermoforming

- Success for the customer: The ZLW toothed belt axis ensures fast positioning of the arm stacker. The system is not only lubrication and maintenance-free, but also has a modular design and can therefore be easily and individually customised.

Problem

The UT-806B stacker is a device for automatically storing and receiving thermoformed packaging from thermoforming machines. The stack configuration is designed for use with the TES 805 and 806 thermoforming machines made by TEPRO SA. The machine has a shoulder that picks up packages, which can move in two axes at high speeds and with high positioning accuracy.The problem was to develop a device that would make it possible to automatically receive parcels in a variety of sizes and shapes while ensuring high process efficiency. The primary objective was to use solutions that do not require lubrication during operation.

Solution

The designers finally achieved a breakthrough with the use of toothed belt axes from the drylin ZLW-1040 system, which enables the arm stacker to be positioned quickly at a gliding speed of up to 5 metres per second. The use of these systems eliminates the need for lubrication and maintenance, significantly reduces the weight of the motors and ensures corrosion resistance. The ZLWA toothed belt axis is based on the modular system of drylin W bearing technology. This means it can be easily and individually modified until the customer has found their desired format. The validity of such solutions has been confirmed in the operation of devices in production environments.