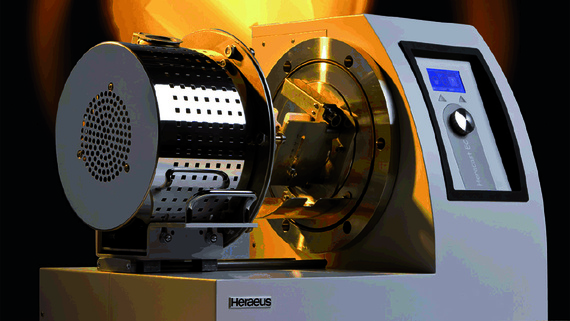

Dental casting machine: reliable linear guides for extreme heat and dirt

drylin W linear bearing for maintenance-free and long-lasting closing mechanism in the dental laboratory

This casting device from Heraeus Kulzer is used in dental laboratories. It is used to make dentures. The used alloys can become several hundred degrees hot. To protect the user, all moving components have been moved indoors in a vacuum. The closing mechanism thereby is subjected to high temperatures and dirt. To make it as durable as possible despite this, it is mounted with a drylin W profile guide.Profile

- What was needed: drylin W linear guide

- Requirements: A long-lasting and reliable mechanism was required, which is not affected by high temperatures and a high level of dirt in the application .

- Industry: Medical technology

- Success for the customer: The drylin linear bearings are 100% maintenance-free and lubrication-free. They have a high wear resistance, are resistant to dirt, dust and moisture and run quietly.

Discover all products for medical technology

Problem

The induction casting unit Heracast EC is a laboratory unit for casting all precious metal and almost all non-precious metal and model casting dental alloys for dental applications with a liquidus temperature of 500°C to 1600°C.To minimise the risk of injury to the device used in dental laboratories, the moving components have been relocated to the interior, where a vacuum prevails. A durable and reliable mechanism was needed to open and close the pressure vessel in which the airless space is created. However, several challenges arose due to the particular nature of the application. The tooth alloys that are cast in the device are several hundred degrees hot, so the mechanism must be able to withstand high temperatures permanently. In addition, there is a high degree of contamination in the application. Finally, the customer was also looking for a solution that would permanently reduce the maintenance effort in order to make the handling of the unit as easy as possible.

Solution

Today, the opening and closing mechanism is solved via a linear bearing system, more precisely with the help of a drylin W profile guide. The linear movement when opening and closing the vacuum pressure vessel considerably minimises wear on the safety-relevant closure system. In addition, the measure allowed the rotary movement of the entire boiler to be decoupled and shifted to the inner area, thus minimising the risk of injury.The drylin linear bearings are used here because they are 100% maintenance-free and lubrication-free. Also decisive here were the high wear resistance, their resilience to dirt, dust and moisture, as well as their quiet operation. They thus qualify for a wide range of applications and are up to 40% more cost-effective than recirculating ball bearing guides.