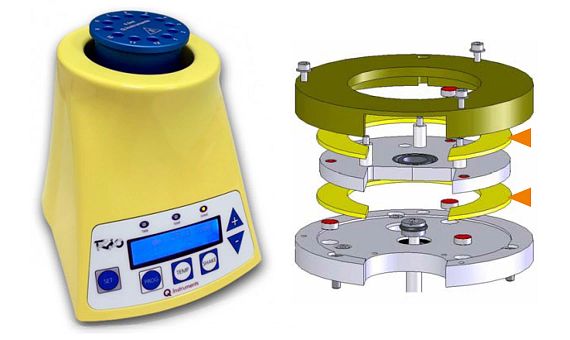

Thrust washers for high precision and maintenance-free use in thermal shakers

iglidur thrust washers at 3,000 revolutions per minute in thermal shakers for laboratories

These medical laboratory devices, known as thermal shakers, must function perfectly in order to deliver accurate results. No vibrations or imbalances should occur when the tubes containing laboratory samples are accelerated at up to 3,000 revolutions per minute and heated up to 99°C. The implementation of orbital and planar mixing movements with igus thrust washers in the Quantifoil Instruments GmbH device results in a significantly more robust, more precise and lower-maintenance technology than that of classic thermal shakers.Profile

- What was needed: iglidur G thrust washers

- Requirements: No vibrations or imbalances should occur when the tubes with laboratory samples are accelerated up to 3,000 revolutions per minute and heated up to 99°C.

- Industry: Medical technology

- Success for the customer: The integrated 3-dimensional controlled guidance of the shaking movement enables for the first time planar and vibration-free working, even at very high shaking frequencies of up to 3000 rpm, while delivering excellent results in tempered mixing.

Discover all products for medical technology

Problem

Due to their design, the commonly used guides for the reaction vessels on elastic elements allow uncontrolled movements that counteract the requirement for reproducible processing and generate massively undesirable vibrations. Furthermore, most of the previous devices are very unwieldy due to their installation size and mass and have a negative influence on their environment due to uncompensated imbalances. A small and light laboratory device suitable for everyday use is desirable, which mixes the samples to be examined in test tubes up to 3000 rpm without vibration and actively tempers them from room temperature up to 99°C.Solution

The implementation of orbital and planar-guided mixing movements by means of thrust washers made of the material iglidur G lead to a significantly more robust, more precise and lower-maintenance technology than that of the classic thermal shakers.The integrated 3-dimensional controlled guidance of the shaking movement enables for the first time planar and vibration-free working, even at very high shaking frequencies of up to 3000 rpm, while delivering excellent results in tempered mixing. The precisely set mixing orbit diameter of 3.0 mm always remains constant. Unwanted lid wetting or spillage of the samples are thus a thing of the past. This eliminates the need for time-consuming centrifugation steps after mixing.