CLAAS with shorter maintenance and development times - thanks to lubrication-free plain bearings at record speed

Profile:

- What was needed: plain bearings in a special shape

- Requirements: quick delivery

- Industry: Agricultural engineering

- Success for the customer: custom-made injection-moulded plain bearings within seven days with the FastLine Service, self-lubricating bearing points, minimal maintenance, long service life and reliability

Company portrait:

The family company CLAAS, founded in 1913, is one of the world's leading manufacturers of agricultural machinery. The company, headquartered in Harsewinkel, Westphalia, is the world market leader in forage harvesters. CLAAS is also the European market leader in another core segment, combine harvesters.

Problem

In a project for CLAAS combine harvesters, a search was made for suitable iglidur® plain bearings for a new bearing point. The sophisticated design of the assembly required a shape that could not be reproduced in the extensive igus® catalogue range. The special shape could only be solved in the injection moulding process with a separate injection mould. It usually takes several weeks to design, manufacture and release such an injection mould for volume production.

Solution

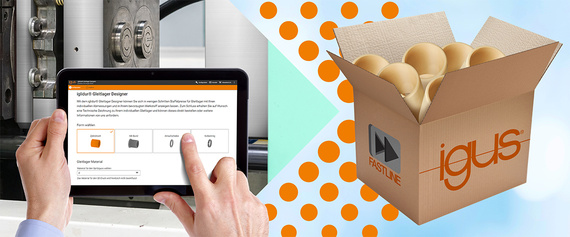

With the igus® FastLine Service , however, this injection mould could be implemented in a very short time. Through consistent optimisation and automation of the design, production and sampling processes and the use of the most modern machines, injection moulded parts from customer-specific injection moulds can be made ready for volume production in just a few days. It took only seven days for CLAAS to submit the first special component for testing after the order had been approved. In this way, the development time of the assembly could be significantly accelerated and the maintenance effort reduced even further.Lubrication-free and maintenance-free bearing points with a long service life

In particular, iglidur® plain bearings help to increase the reliability and service life of machines that are becoming more and more powerful, despite their increasing technical complexity. iglidur® plain bearings do not require any lubricating grease for operation and therefore do not need to be lubricated. In this way, the maintenance of the bearing points can be reduced to a minimum. This effectively contributes to increasing the productivity and reliability of the machines.

Individual injection moulded plain bearings received in seven days - igus® FastLine Service

✅ Instant pricing✅ Get the individual plain bearing in seven days

✅ Maximum price transparency by comparing the manufacturing processes

✅ Everything from a single source: from the injection mould to the plain bearing

Go to the FastLine service