Hygienic and maintenance-free linear modules in beverage control equipment

Linear plain bearings contribute to food-grade testing systems for the beverage industry

Since the most important safety standards for the protection of consumers are applicable in beverage and food technology, designers need products that do not require external lubrication. This is the only way to rule out contamination in food or beverages. Furthermore, there is the need, amongst other things, for resistance to chemicals and corrosion, freedom from maintenance and low moisture absorption. We meet these concerns with our products and ensure years of functional reliability.Profile

- What was needed: drylin® SHT linear modules; easy chain® energy chains

- Requirements: Only the top quality structural parts could be used in the high-quality test systems; safety standards in beverage and food technology require products that do not require external lubrication; in addition, there are, amongst other things the need for resistance to chemicals and corrosion, freedom from maintenance and low moisture absorption.

- Industry: Food industry, testing systems

- Success for the customer: drylin® SHT linear modules offer corrosion and chemical resistance as well as freedom from maintenance, they are easy to clean and require no lubrication; the customer can meet all hygiene requirements and enable his own customers to use the products for years to come; no complaints about the systems are known to date

Problem

Indspect GmbH focuses on the beverage industry and supplies control devices for industrial testing processes according to customer-specific requirements. Thereby, the focus is on the user-friendliness of the measuring systems. Even with complex measuring procedures, every user should be able to operate the system after a brief introduction. Therefore, a graphical, intuitive user interface together with contextual help is the basis of each device type. Indspect develops an individual solution for each application and offers advice, support and staff training. The objective of the measurement technology experts is to ensure the use of high-quality products and optimised work processes that take account of the respective local conditions as well as an optimal quality control through a high production standard.Indspect's devices consist of a camera system with appropriate sensor technology and have proven themselves on the market. One focus here is on a wide variety: labels, seals and their colour shades, the fill level, bottle shapes, defects in the glass and other technical production processes are checked.

The different adjustments on the systems require Indspect to provide high-quality testing systems, in which only the highest quality structural parts are used. Since the highest safety standards apply in beverage and food technology to protect consumers, designers need products that do not require external lubrication.

the need, amongst other things, for resistance to chemicals and corrosion, freedom from maintenance and low moisture absorption.

Solution

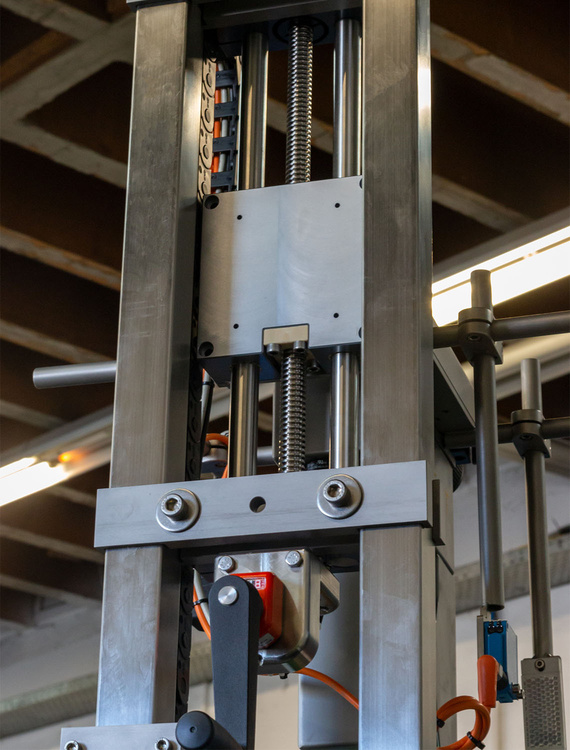

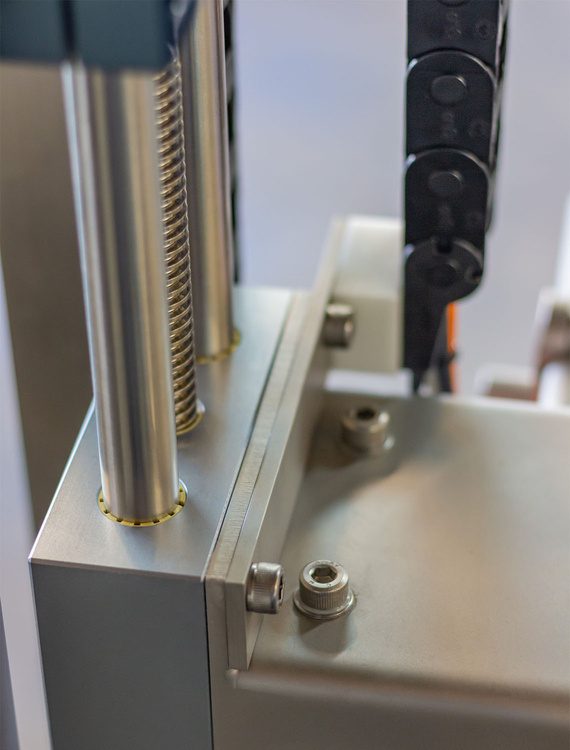

In the case of linear systems, we are already a long-standing partner of Indspect. The drylin® SHT linear modules that are used offer resistance to corrosion and chemicals as well as freedom from maintenance. They are easy to clean and have low moisture absorption. In addition, they are light and do not require additional lubrication. The lead screw linear units are recommended for aggressive environments. A stainless steel version with corrosion-free steel components also meets the highest demands of the food industry.The manufacturer already knew the products from previous collaborations. He is thereby able to meet all hygiene requirements and keep the aging process low. This enables customers to use the system for many years.

The camera and lighting also move along in the adjustments in the Indspect devices. The drylin® SHT was used here almost from the beginning. An appropriate energy chain was included a little later. In large systems where many cameras work, it secures the cables and therefore the operation. The E14 series easy chain® energy chain is easy to fill quickly along the outer radius. A "push-button design" safely holds the chain links together. A small pitch ensures quiet, smooth operation.

To date, there have been no known complaints about the systems, and it only returns to the manufacturer if something is rebuilt or a part is added. Maintenance work is also not necessary thanks to the lubrication-free nature of the linear systems. In this way, the high expectations of the food industry for the linear systems could be met right from the start. This also applies if entire units - such as linear systems - are on the order form. Extensive assembly work is completely eliminated.

Michael Pfeiffer, Head of Design at Indspect