Durable and lubrication-free linear bearings for high-performance cutting machines

Polymer bearings or a cutting machine with high-speed depositing system in the food industry

For over 20 years now, the Treif Maschinenbau GmbH from Westerwald has been relying on plastic plain bearings in their machines, plants and systems for slicing food items. Installed in 1993 for the first time in a multi-tooth gripper, today virtually our complete range of lubrication-free and maintenance-free polymer bearings are used. The technical demands are rising steadily.Profile

- What was needed: drylin linear plain bearings, drylin shaft guides, drylin linear liners, iglidur plain bearings

- Requirements: High dynamic loads due to high speed of the depositing system; continuous operation; low wear; long service life; lubrication-free bearings requiring strict hygiene specifications and are resistant to chemicals and have low moisture absorption,

- Industry: Packaging, food industry

- Success for the customer: iglidur and drylin bearing components have low coefficients of wear and friction are, lubrication-free and corrosion-resistant as well as tough and economical

Problem

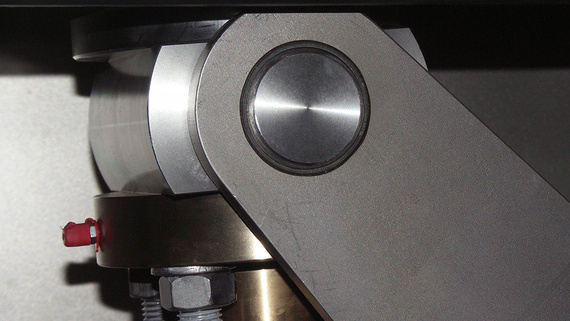

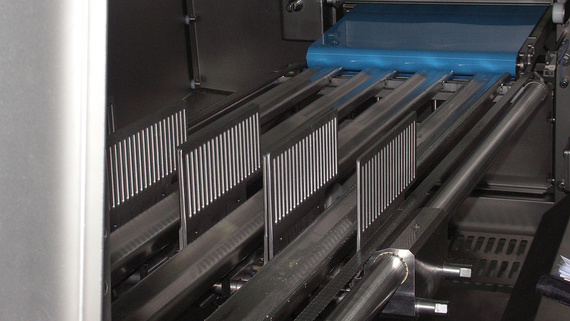

In the slicing division of Treif Maschinenbau GmbH in Oberlahr, equipment such as the high-performance slicer 'Divider 880' are produced for the food industry.One of its technical features is a high-speed depositing system whose task is to feed the cut product out of the cutting area and into the packaging machine. In order not to interrupt the product flow, a kind of fork is shot into the product flow, which results in enormous accelerations of 25 G. At the same time, the slices must at all times be clean and absolutely uniform. The toothed belt, with which the fork is accelerated to 25 G, are synchronously driven and deflected. The roller bearings initially installed in the deflection had to be sealed. Since the seal generated friction that had a negative effect on the drives, a better solution was sought here.

Challenges also arose for the cutting system itself. Empty cuts (knife rotations in which no product is cut) had to be avoided. They bring on high dynamic loads in the product. The blade performance and a chamber size of 450 x 130 mm for inserting the products to be cut result in physical requirements for which the performance data of the machine elements must be met.

Due to the complex requirement profile of continuous rapid movements, the plain bearings in question were tested by Treif itself over a period of months, with the focus sometimes also on wear results and service life calculations.

In the food industry, there are also strict hygiene regulations that must be observed, e.g. lubrication-free lifting and cutting systems are required so that no product contamination can occur at any point during cleaning with water and the different cleaning agents. In addition, chemical resistance and low moisture absorption are important. And since the slicing machines sometimes work three shifts up to six days a week, their service life need to be coordinated. Unscheduled maintenance should be excluded.

Solution

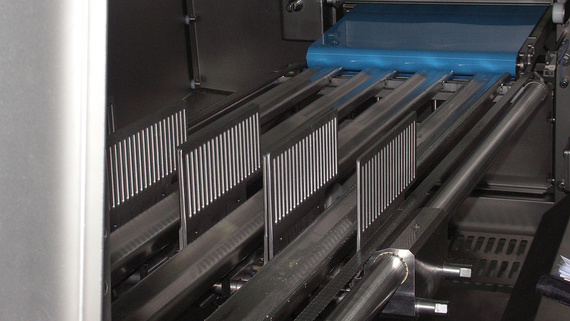

In the area of the deposition system for inserting the sliced pieces and also in the actual slicing machine, different lubrication-free and corrosion-free, open and enclosed drylin linear plain bearings made of the materials iglidur J and iglidur J200 are used. Due to their wear and friction properties they are suitable for most linear applications. Designed for dry operation, their applications are protected from contamination by grease and oils, i.e. active lubrication.Furthermore, plain bearings of the iglidur J and iglidur G material series display their strength in the high-performance slicing machine. They are sturdy, economical and universal. All machine elements made by igus prove their capability in high-speed slicing and in depositing the sliced products.

Slices holder

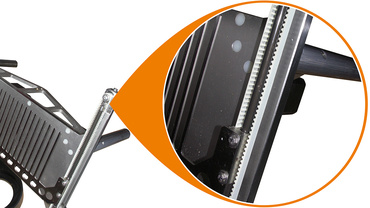

Today, externally positioned soft stainless steel shafts, which are resistant to chemicals are used in combination with open drylin linear liners.

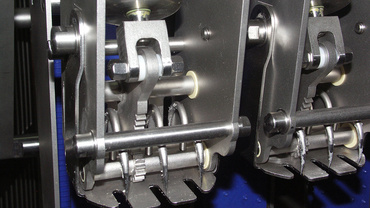

Depositing fork

Additional lubrication-free polymer bearings made of the corrosion-resistant iglidur J type series are used in the area of the depositing fork for mounting the slice holder. They ensure the pivoting movement of the drive to the pneumatic cylinder. The material is resistant to weak acids, diluted alkalis and many disinfectants used in the food industry. The intensive cleaning of machines in the food industry thus presents no problems for the polymer bearings.

Pre-gripper / Feeding tower

The use of the polymer technology goes even further: soft stainless steel shafts and linear sliding elements secure the linear stroke of the pre-gripper for the forward feed of the slices. Universal iglidur G polymer bearings are used in the pivotal mounting of the feeding tower. They are wear-resistant, insensitive to dust and dirt and very economical. All materials that come into direct contact with food are FDA-compliant and thus safe in the long-term.