Technical data:

► What was needed: Lifelong freedom from clearance of the adjustment unit and thus precise glue application without maintenance► Requirements: No sticking due to the fine wood dust, high precision, absolute freedom from lubrication and maintenance, flexibility in production

► Products used: Anti-backlash trapezoidal lead screw nut, trapezoidal lead screw made of stainless steel

► Success for the customer: The clearance-free and maintenance-free nature of the newly developed adjustment system has convinced Brandt so much that they are thinking of basically converting all lead screws in the machines to the maintenance-free anti-backlash system. "That way we can further increase the reliability of the machines," says Ralf Garnjost with confidence. In the edge banding machines, various tribo-optimised polymer bearings are also proving themselves in special shapes. "Freedom from lubrication pays off in all areas. For us lubrication and dust are incompatible at all points."

Request free sample

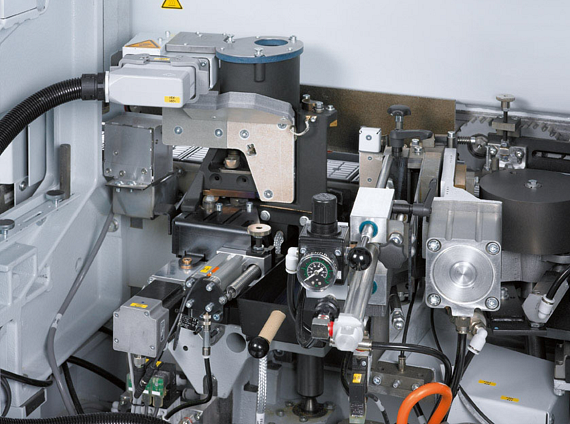

Lubrication-free and clearance-free dryspin lead screw drives ensure precise glue application

What happens when fine and the finest wood dust encounter the lubricant? Adhesion is inevitable. The functionality of woodworking machines can be permanently impaired. For this reason, a medium-sized company relies on lubrication-free and maintenance-free lead screw drives with anti-backlash nuts in its new development of an adhesive application system for edge banding machines, which ensure lifelong zero clearance of the adjustment unit and the precise application of glue.

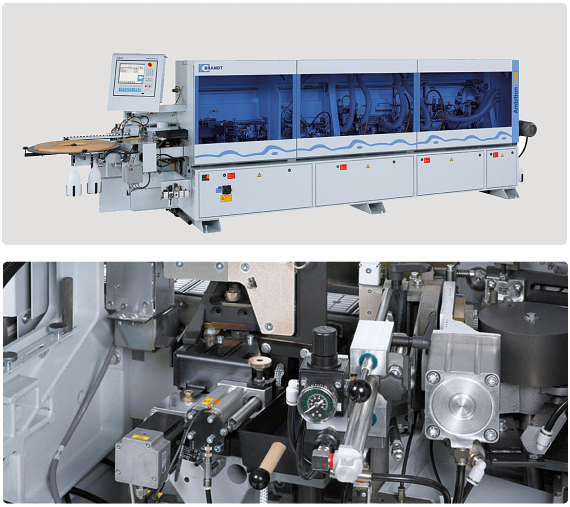

"The product variety in furniture continues to increase, consumer wishes are becoming increasingly diverse. For these reasons, our customers want the greatest possible flexibility in production," explains Ralf Garnjost, mechanical engineer and head of design at Brandt Kantentechnik GmbH in Lemgo. Whether it is sophisticated shop fitting, unit 1 production for individual requirements, living room and bedroom furniture or functional office furnishings: the specialist for edge banding technology, a member of the globally active Homag Group, offers the right solution for every requirement profile. "From the simple entry-level machine for the carpenter around the corner up to the highly automated edge banding machine, our modular system includes customised machines for all customer requirements and processing tasks," Ralf Garnjost summarises.

The product range of the company, founded in 1955, is geared to all trends in customer requirements and machining tasks. The focus of machine development is on practical and economical solutions that guarantee the best possible production results for customers worldwide. Production takes place in Lemgo with around 280 employees; there are also locations in the Czech Republic, Poland and China. With an export share of around 80 percent and customers in over 90 countries, the edge band specialist is one of the leading global suppliers.

Glue application with precision

The latest developments include the QA 45 glue application system, which is available as an option from a certain machine size. It is characterised by, among other things, short heat-up times as well as fast changeover options and thus a high degree of flexibility when processing a wide variety of adhesives, edges and board materials. "With the system, we want to create the possibility of automating adhesive application. In this way, we offer our customers more ease of use. Otherwise, the adhesive is applied more or less by sight," says Ralf Garnjost, describing the original situation. "Our goal was to create an inexpensive, yet structurally sound solution that would stand the test of time in everyday operations."

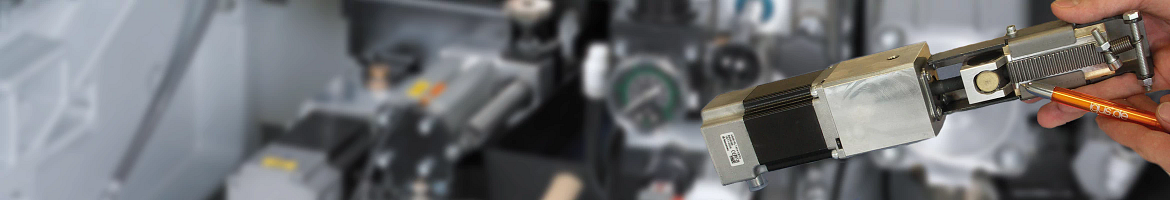

Besides the automatic cleaning function, one of the innovations of the new glue application system is a clearance-free adjustment, which was implemented in collaboration with the company igus GmbH, Cologne. At the heart of this adjustment is the anti-backlash nut, which was presented as a standard product at the Hannover Messe Industrie 2010. "Backlash" refers to the play at reversal, which is caused in a lead screw drive by the axial clearance.

The anti-backlash lead screw nuts offer many advantages:

► Reduction of backlash over the entire service life

► Permissible wear is ensured

► Non-lubricated and extremely dirt-sensitive lead screw drive

► No adhesion of dirt and dust to lubricants

In the glue application system, anti-backlash lead screw nuts have been used for metric threads as a special development for several months: Lubrication-free, vibration- and noise-dampening, they ensure maximum precision.

The anti-backlash lead screw nuts offer many advantages:

► Reduction of backlash over the entire service life

► Permissible wear is ensured

► Non-lubricated and extremely dirt-sensitive lead screw drive

► No adhesion of dirt and dust to lubricants

In the glue application system, anti-backlash lead screw nuts have been used for metric threads as a special development for several months: Lubrication-free, vibration- and noise-dampening, they ensure maximum precision.

Precise travel

"All the usual solutions tend to be susceptible to maintenance in everyday operation due to the difficult environmental conditions in woodworking," explains mechanical engineer in the design department, Thorben Fritz, who was largely responsible for the development of the adjustment unit. "Due to our many years of experience with tribo-optimised plain bearings from igus in our machines, we were convinced right from the start that we could guarantee precise format adjustment in the long term with lubrication-free machine elements." In the area of lead screw systems - up to ten axis units cover the most diverse work in an edge banding machine - the edge specialist has so far relied on brass nuts, which are, however, not backlash-free. Due to the existing backlash, the desired position is not always hit, the repeatability is poor.With the help of the adjustment, the adhesive application on the edges is dosed. If the travel is not accurate, there are deviations of several tenths, which reduces the quality of the adhesive application. For this reason, clearance-free adjustment was very important in the development of the application system. Classic solutions such as lead screw nuts braced against each other have been quickly discarded. "These are manifold design approaches that are not only very complex, but also require a relatively high drive torque of the actuator," explains Ralf Garnjost. "In contrast, we try to drive our axis systems with a relatively low torque." The low coefficients of friction of the new lead screw nut system provide the required low drive torque.

However, it is not just about the zero clearance of the adjustment, but also the issues of zero maintenance, reliability, durability and long service life that play an important role. The atmosphere around the edge banding machines is extremely dusty. If greased systems such as ball screw drives are used, wood dust and particles come and accumulate on them. The range of adjustment would have to be encapsulated in this case and continuously relubricated. Regular maintenance, even in less accessible places, would be the result. "That is cumbersome and expensive, which is why we have relied on maintenance-free linear technology components right from the start," explains Ralf Garnjost. They permanently ensure the necessary operational safety.

Added to the dust is high ambient temperatures, which can be up to 200 °C in the hot melt adhesive range. In the surroundings of the glue application system, they still amount to up to 80 °C, which can influence the functionality of the installed machine elements in the adjustment unit. But even here, no complaints were found in endurance tests. The all-round material iglidur J provides the necessary temperature resistance.

Added to the dust is high ambient temperatures, which can be up to 200 °C in the hot melt adhesive range. In the surroundings of the glue application system, they still amount to up to 80 °C, which can influence the functionality of the installed machine elements in the adjustment unit. But even here, no complaints were found in endurance tests. The all-round material iglidur J provides the necessary temperature resistance.

From trapezoidal to metric thread

Before the development of the anti-backlash system usually two mutually braced nuts ensured the necessary zero clearance, the edge specialist today uses only one component. The challenge for the company igus was to produce a custom-made special part with metric thread from a series product with a trapezoidal thread without sacrificing performance. "Since we have been manufacturing lead screw nuts for almost 15 years, we have the necessary experience to implement such special solutions quickly and reliably," says Dominik Hartmann, Project Manager drylin TR lead screw drives. After adapting the geometry of the nut in Cologne to the specifications of the company Brandt and appropriate samples were produced, various functional tests began in Lemgo. "We tested 40 000 strokes without sacrificing zero clearance," says Thorben Fritz. "This was the final proof that the anti-backlash function also works with metric threads." After a lead screw nut system was dismantled after a running time of nine months, and sent to Cologne for inspection, igus could also confirm that the lead screw drive works without a measurable increase in clearance.Ralf Garnjost adds to that. "However, our application does not depend on the number of strokes, but on the reliability of the adjustment system. The movement sequence of the glue application system is relatively limited. It is not a continuous, but a discontinuous movement. Nevertheless, it must be ensured that it always works and that no adhesions occur." With regard to the number of cycles tested in advance, however, the edge specialist assumes that the service life expectancy of the complete adjustment unit in everyday operations is several years.

General conversion to maintenance-free linear systems and plain bearing solutions

The freedom of clearance and maintenance of the newly developed adjustment system has convinced Brandt so much that it is thinking of converting all lead screws in its machines to the maintenance-free, anti-backlash system. "That way we can further increase the reliability of the machines," says Ralf Garnjost with confidence. The companies have been working together for a number of years. In the edge banding machines, various tribo-optimised polymer bearings are also proving themselves in special shapes. "Freedom from lubrication pays off in all areas. Lubrication and dust don't mix at all in any of our places."

A special profile based on the drylin W linear guide is also currently being developed, which has the same dimensions at the relevant points as the recirculating ball bearing guides previously used. "Without major design changes, we are saving parts," concludes Ralf Garnjost. "This not only pays off in terms of warehousing, purchasing and assembly, but also simplifies the replacement of the relevant parts in the event of maintenance and servicing."

A special profile based on the drylin W linear guide is also currently being developed, which has the same dimensions at the relevant points as the recirculating ball bearing guides previously used. "Without major design changes, we are saving parts," concludes Ralf Garnjost. "This not only pays off in terms of warehousing, purchasing and assembly, but also simplifies the replacement of the relevant parts in the event of maintenance and servicing."

Would you like to test the dryspin technology?

Ask for a free sample of a lead screw drive here!

► Your own lead screw drive sample► A lot more information

► Simple explanation of the dryspin technology

Order a dryspin sample here