Maintenance-free in rail transport due to lubrication-free lead screw drives

How can the wear on sliding doors in trains be reduced by 25%?

The number of passengers on public transport has been increasing steadily for 20 years. This is good news for the industry, but it also places an increasing burden on the rail network, trains and their individual components, such as sliding doors. Long-lasting lead screw drives which meet the high requirements, such as minimising wear and increasing service life are in demand. drylin lead screw technology is convincing and has already proven itself in many railway applications.

Can maintenance costs in bridging gaps be avoided?

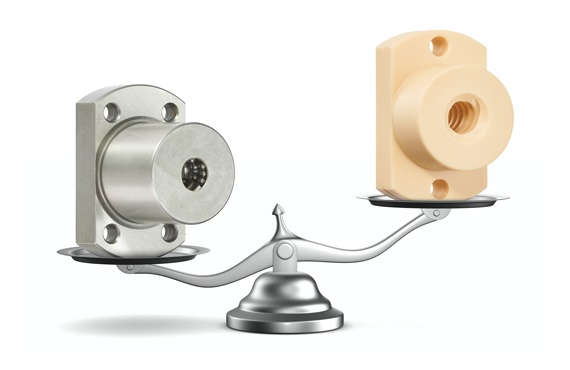

How would it be if maintenance efforts and costs were reduced and regular lubrication became unnecessary? And what if efficiency and effectiveness increase significantly? drylin lead screw technology offers the perfect alternative to conventional metal lead screw nuts for railway technology. It is completely lubrication-free and maintenance-free and therefore ideally suited for 24/7 operation.

Find out more about how to improve the technology of your application and reduce costs at the same time:

► Up to 50.9% more cost-effective than metallic sliding lead screw nuts

► Up to 69% compared to comparable plastic lead screw nuts

► Up to 50% compared to ball screw systems*

*Due to a deviating thread profile, lead screw & nut must always be replaced, even for the same thread size

Lead screw nuts

► Very different types

► Save up to 50.9% in costs

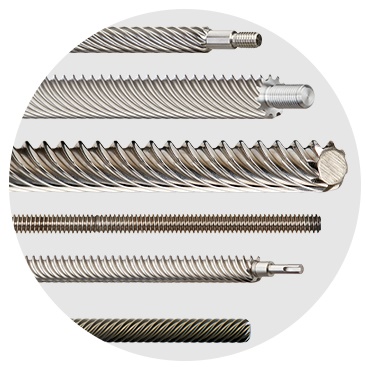

Lead screws

► High helix, trapezoidal and metric lead screws

► Up to 30% longer service life

Special geometries & accessories

► Accessories for lead screw nuts & lead screws

►Our experts are happy to assist you in person

Customer application examples

In railway technology

In railway technology

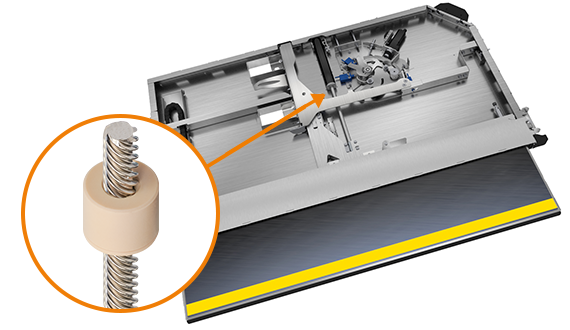

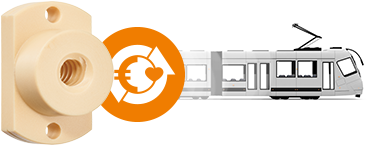

Sliding steps on trains

drylin® lead screw drives keep gap bridging moving on trains

no jamming or sluggishness during continuous sliding step operation

► Requirement:

Lightweight, weather-resistant, few components, low clearance height, reduced costs

Switchgear for a railway control panel

drylin® TR high helix lead screw nut in one switchgear

Benefits:

► Dirt-resistant► Lubrication-free solution

► No self-locking due to high pitch

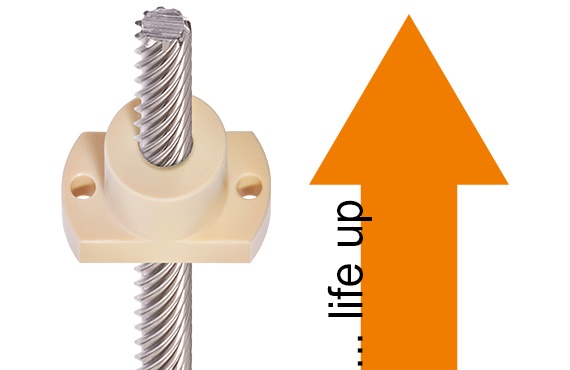

25% less wear

Our lead screw technology convinces in the test laboratory

The evaluation of the wear test for the product with the dimensions 10x3 made of stainless steel showed that our dryspin® thread Ds10x3 can achieve a wear rate up to 25% lower, a service life up to 25% longer and greater efficiency compared to the competition and the trapezoidal thread Tr10x3 .

30% longer service life

Thanks to the unique dryspin technology

The larger spaces between the individual dryspin threads result in a higher share (factor 1.3) of tribologically optimised polymer in the threads. More wear-resistant material and higher levels of efficiency are crucial for a service life that is up to five times longer compared to conventional high helix threads.

100% lubrication-free and maintenance-free

Ideally suited for applications in continuous operation

From railway doors and bridging gaps, up to track adjustment - the freedom from lubrication and maintenance of the lead screw drives enables their use in almost all areas of railway technology.By using the tribologically optimised, iglidur high-performance polymers, dust and dirt cannot stick to the lead screw drive. The dryspin technology is also one step ahead in humid environments: it is 100% corrosion-free. Therefore, a smooth operation is guaranteed throughout the entire application. Discover maintenance-free dry operation in the dryspin thread shop.

Saves weight by up to 88%

Low weight means energy efficiency

Weight saving is a major issue in almost all means of transport. Because less weight means less energy consumption, which in turn leads to a reduction in CO2 emissions. Developers from the rail transport sector want to become fully CO2-neutral by 2050.Metal lead screw nuts are robust – and heavy. drylin polymer lead screw nuts offer the perfect alternative for many applications in railway technology. They are light, reliable and durable. Wherever low weight is important, our light lead screw nuts made of polymer are perfect, because you achieve a weight saving of up to 88%.

Cost down

Save 50.9% of the cost

dryspin technology convinces in any comparison of prices. It not only distinguishes itself due to its several technical advantages over its metallic counterpart, but is also 50.9% more cost-effective.

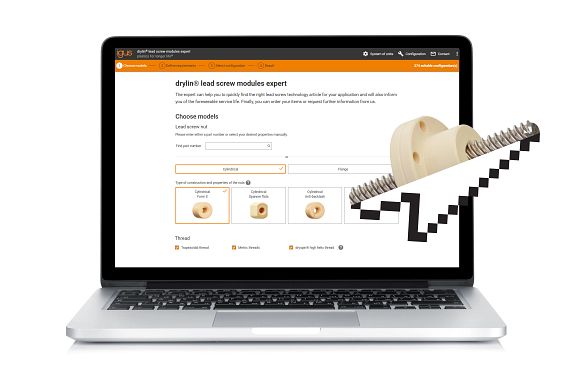

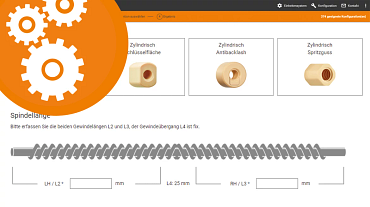

Customer-specific designs configurable online

The expert can quickly help engineers find the right lead screw system part for their application and will also predict service life.

The configurator enables engineers to quickly find the right lead screw and machine the pins from both sides. The application generates a dimensioned drawing of the configuration.

Free dryspin® sample

Your own lead screw drive with the most important information for railway technology at a glance:► Free from lubrication and maintenance

► Higher efficiency and longer service life

► Media resistance

► Quiet, vibration-free operation due to rounded tooth geometry

► Service life predictable online

Further application examples of drylin lead screw technology:

| Beverage industry | Wood industry | Camera technology | Food industry | Medical technology | Model making |

| Furniture & industrial design | Robots | Solar technology | Textile industry | Packaging industry | etc.